Lecture 3D Geometry Processing

Scanning and Fabrication

Prof. Dr. David Bommes

Computer Graphics Group

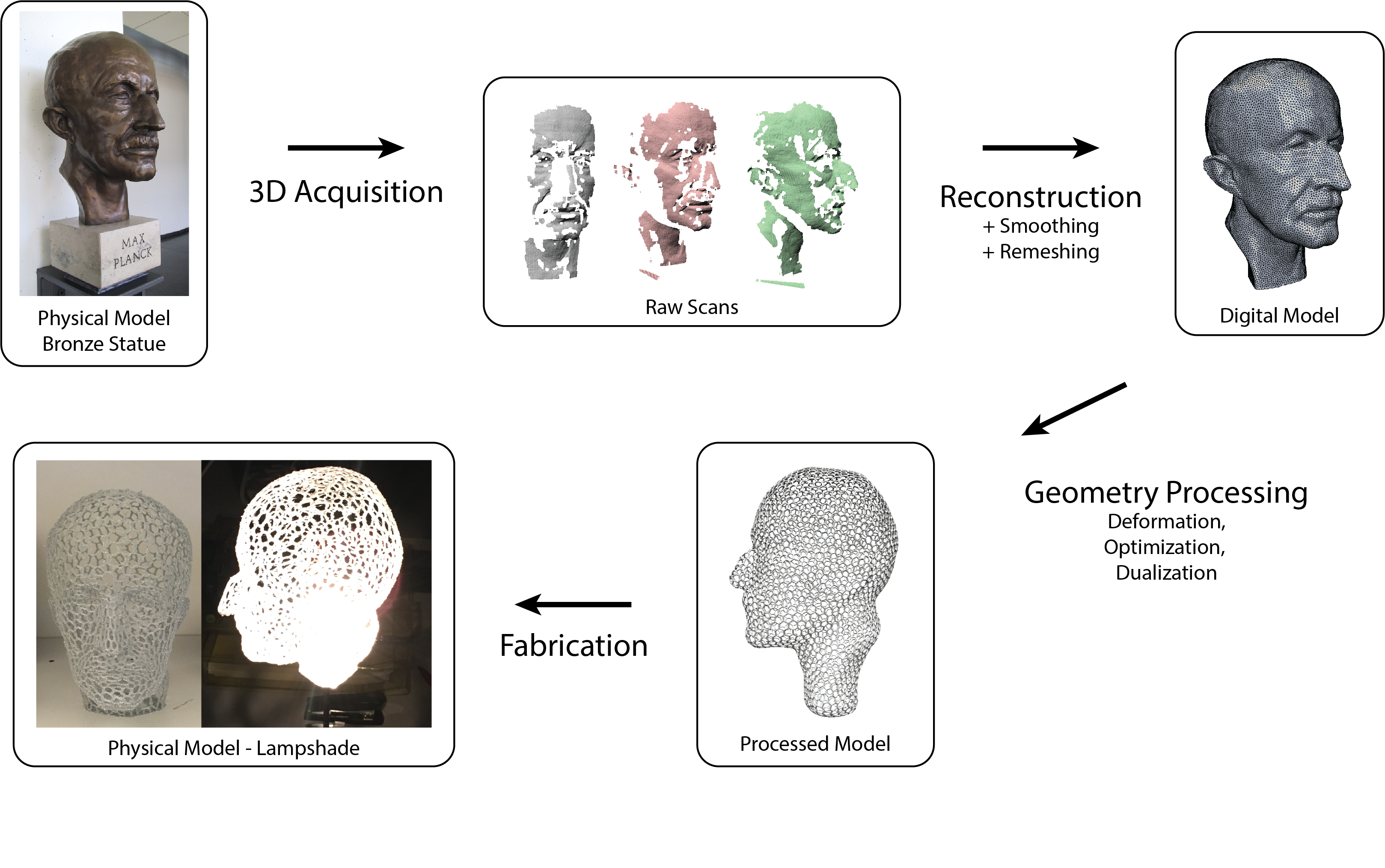

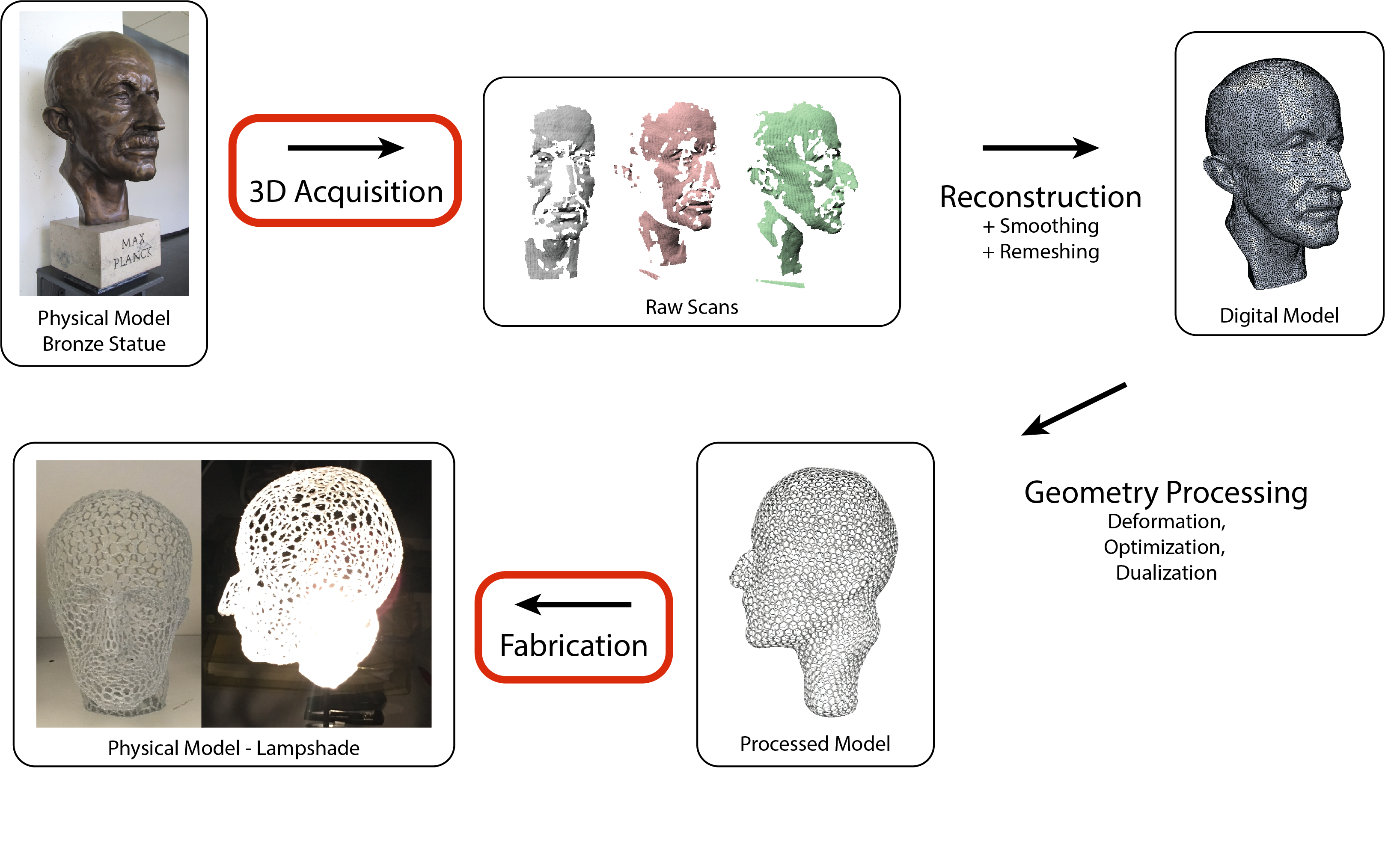

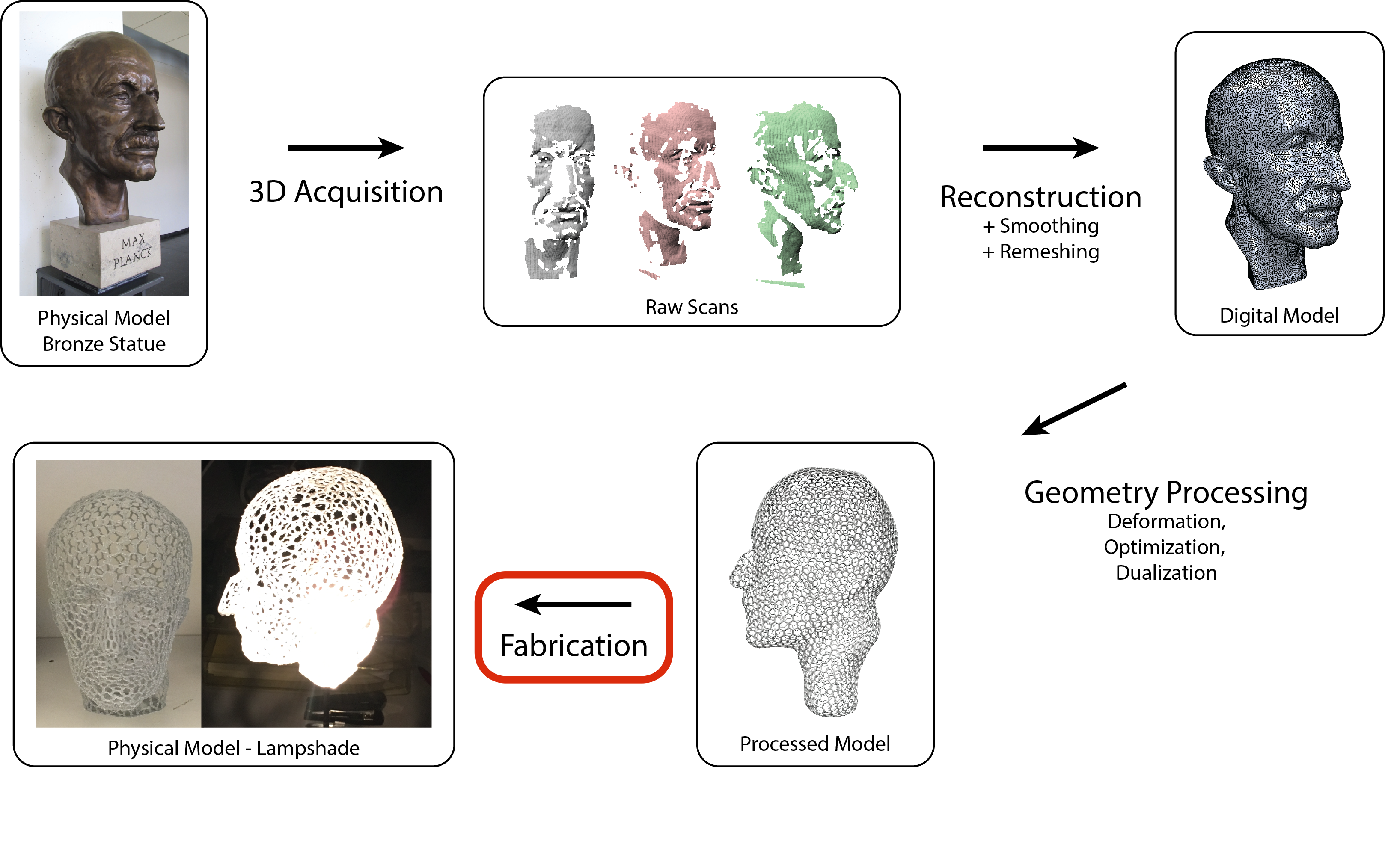

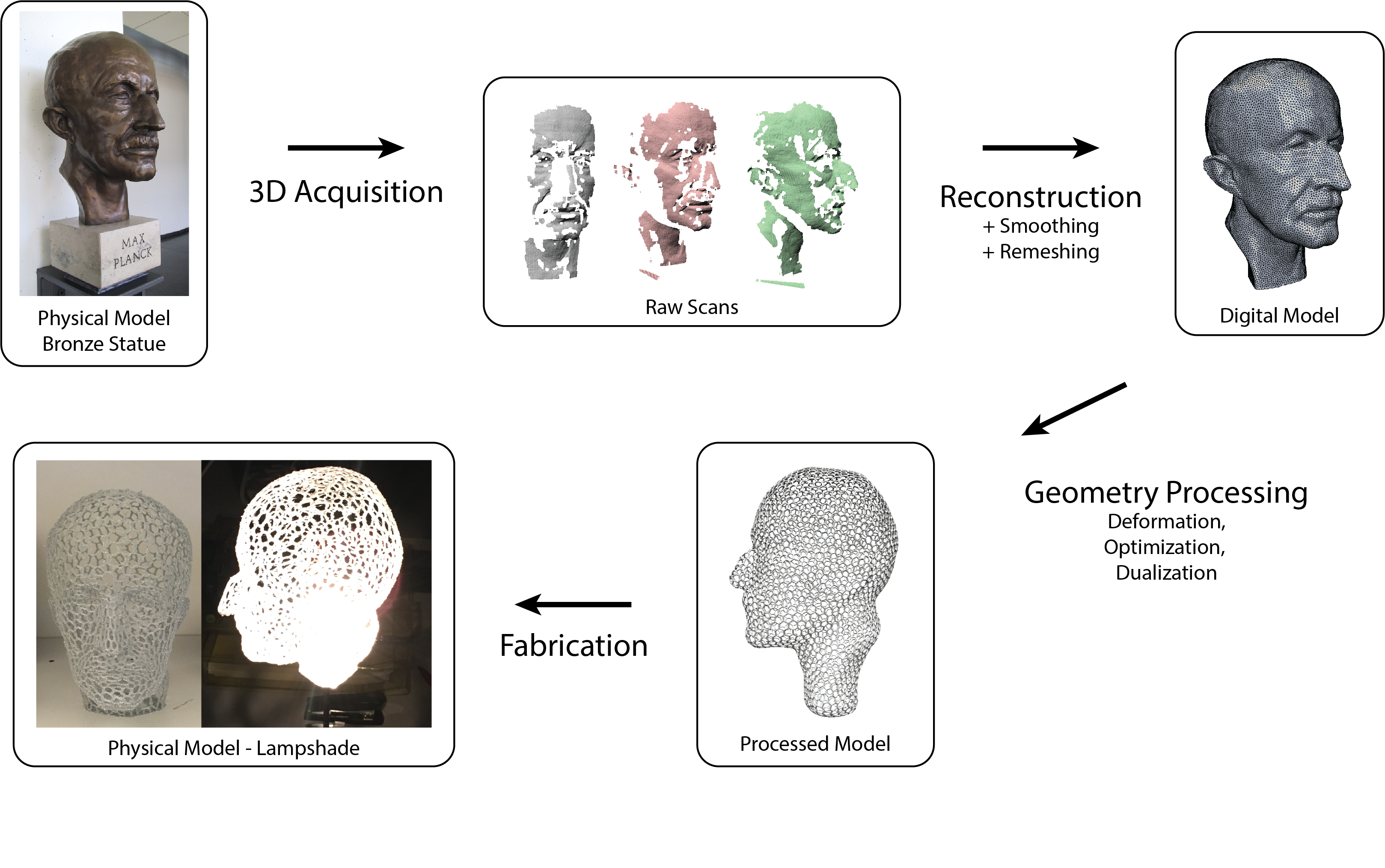

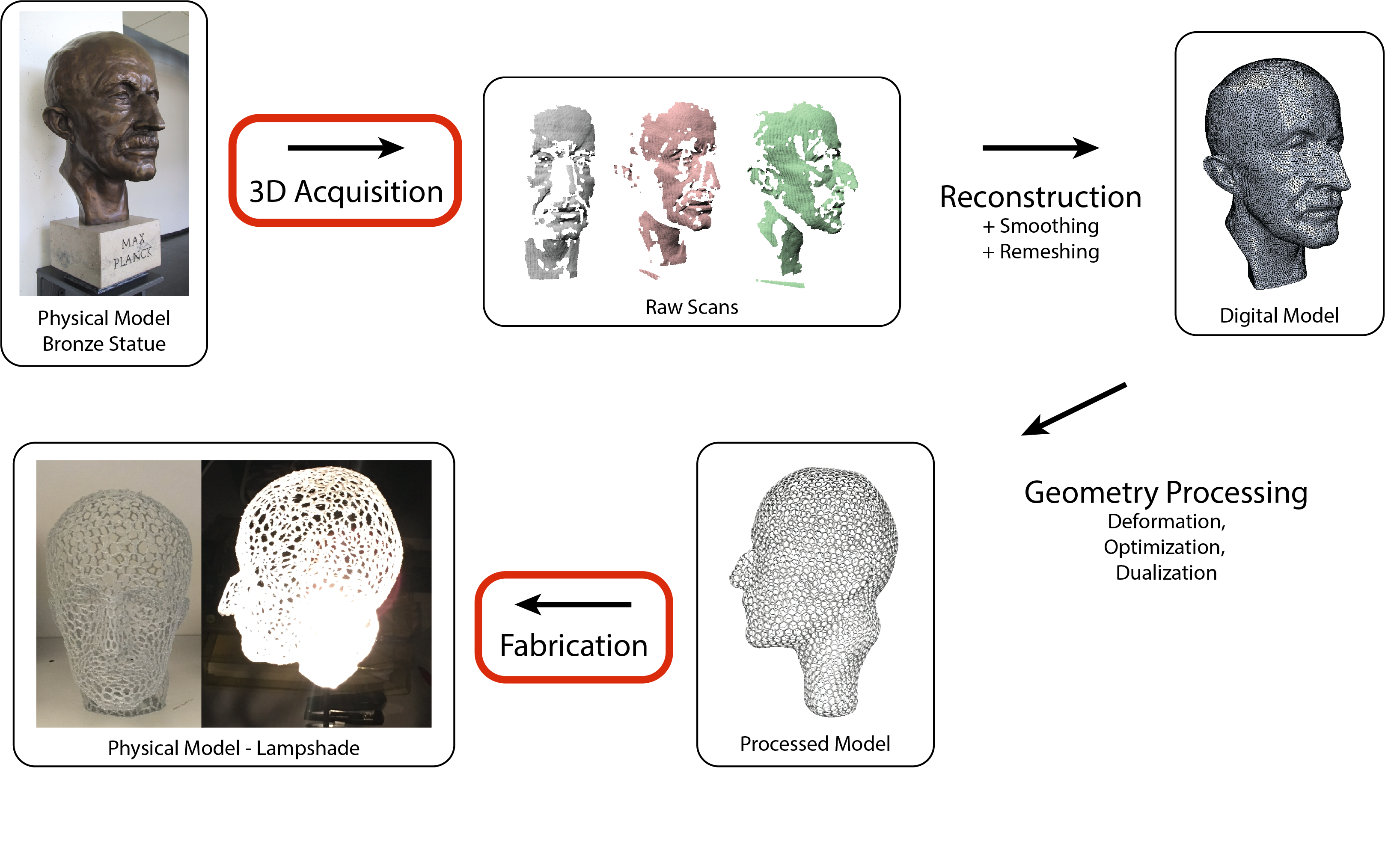

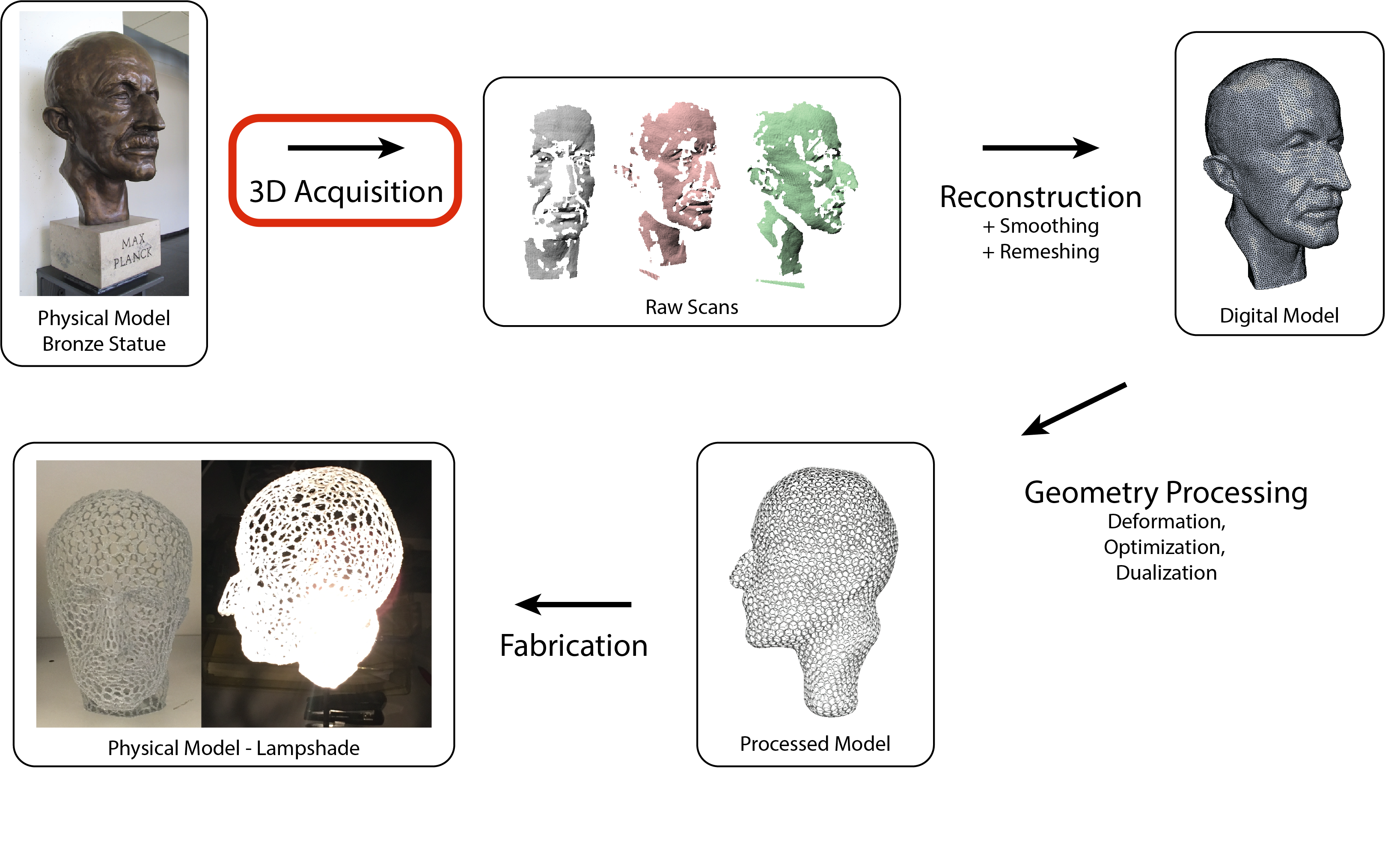

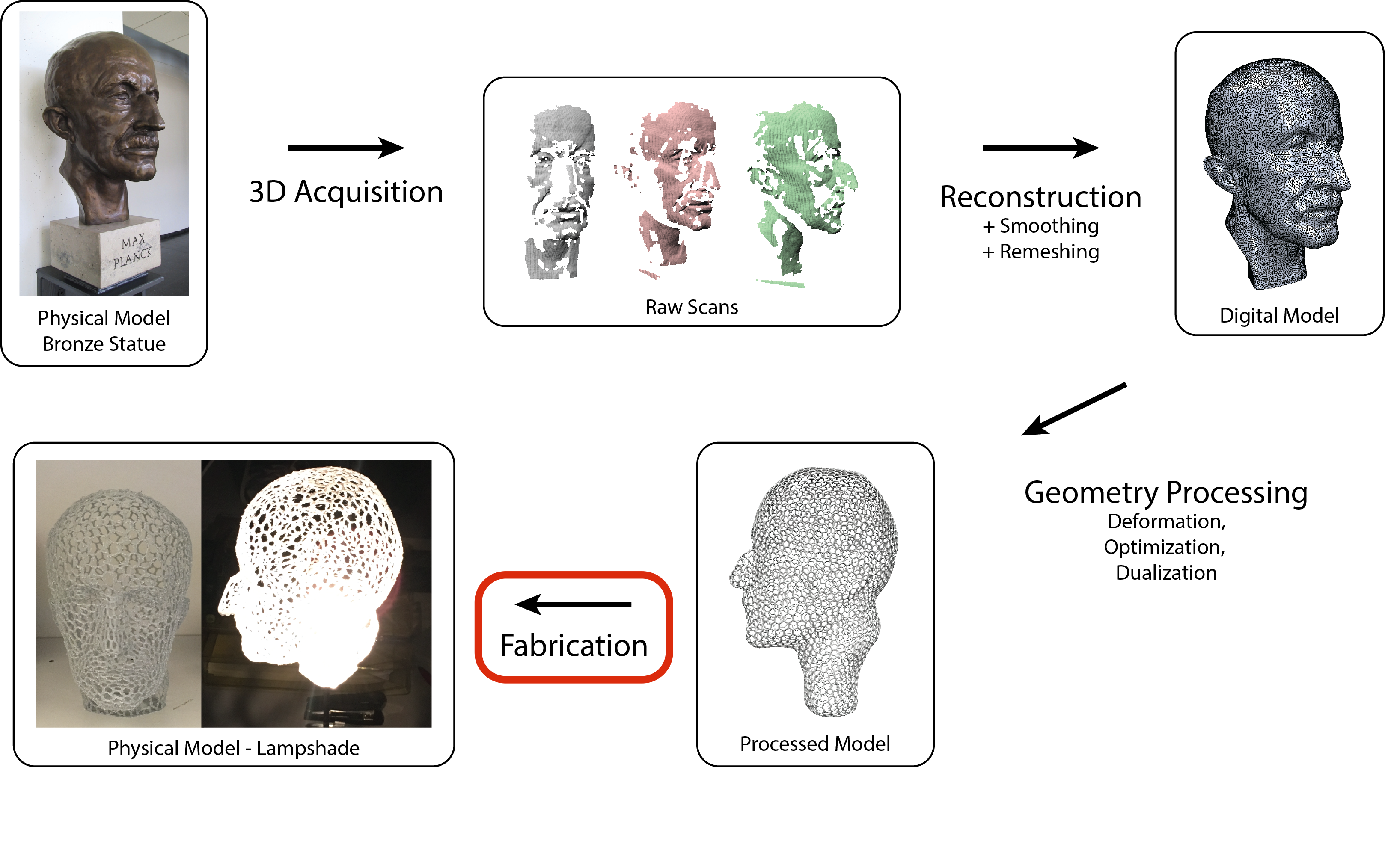

3D Content Creation Pipeline

3D Content Creation Pipeline

3D Content Creation Pipeline

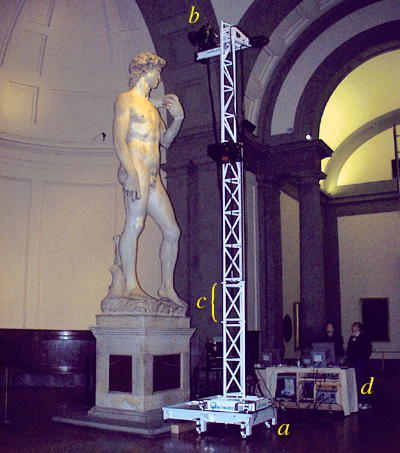

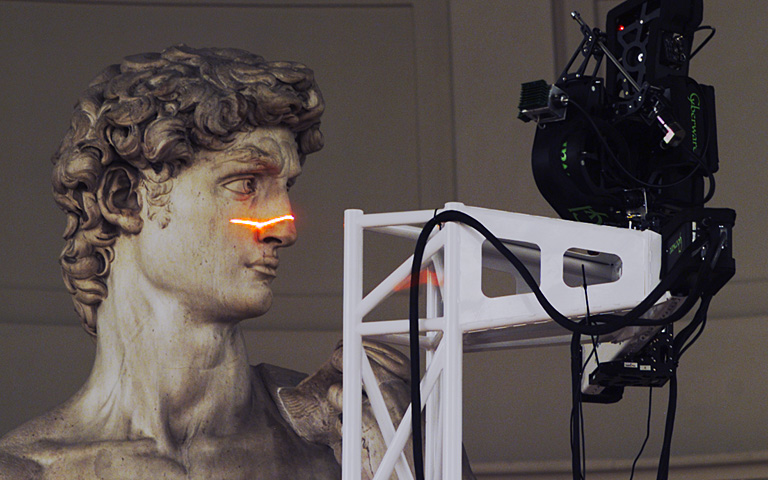

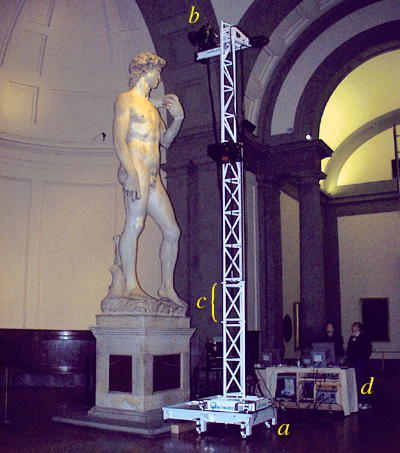

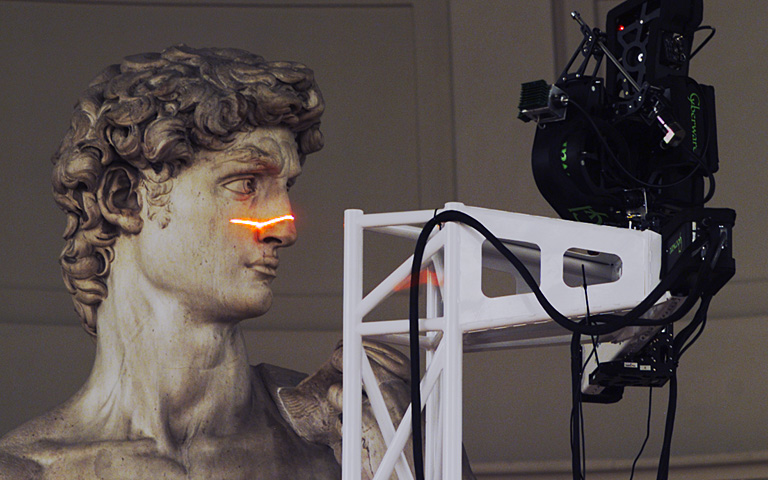

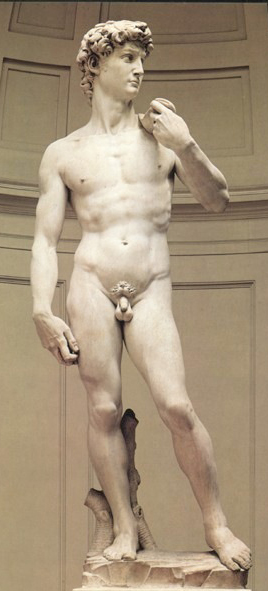

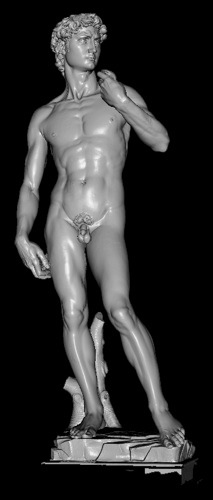

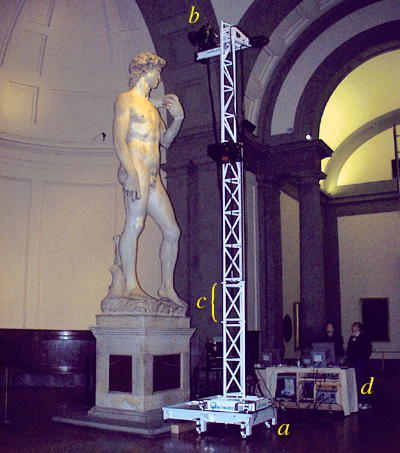

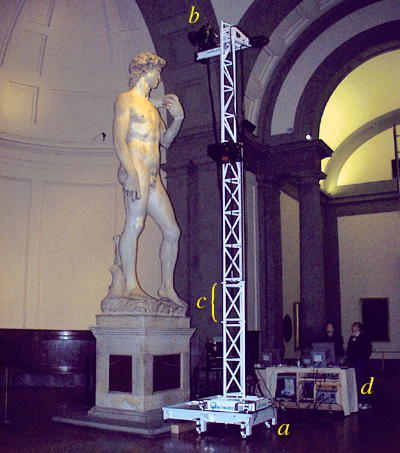

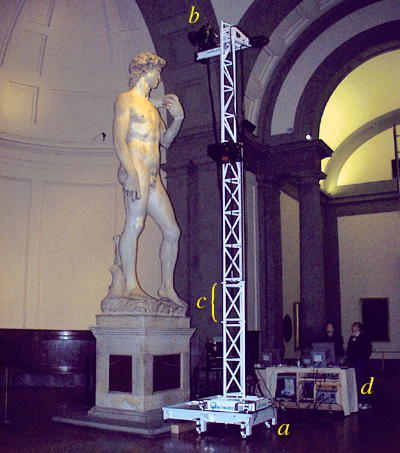

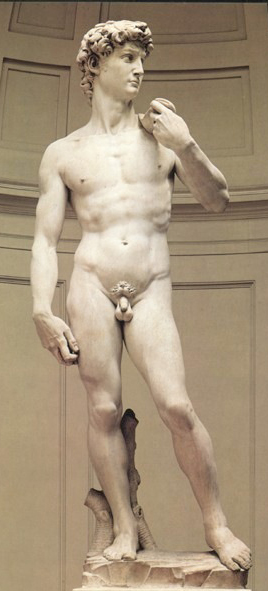

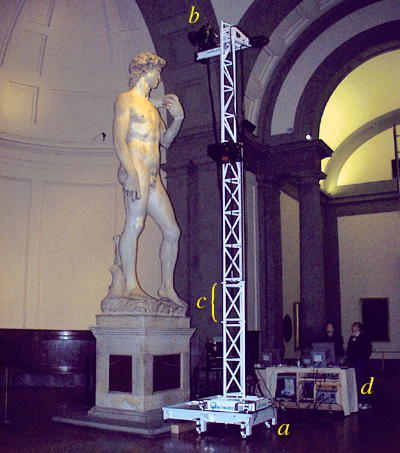

Digital Michelangelo Project

- Scan large statues (~5m) at high resolution (1/4 mm)

- Capture chisel marks

- Record color/reflectance for re-lighting

Digital Michelangelo Project

- Several challenges

- Fragile, precious sculptures

- Bulky equipment

- Visibility

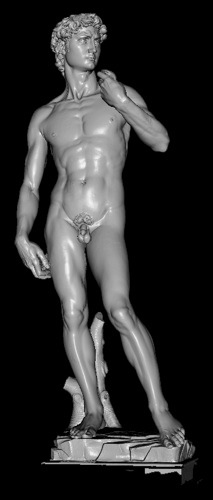

Digital Michelangelo Project

1G sample points

1G sample points  8M triangles

8M triangles  4G sample points

4G sample points  8M triangles

8M triangles

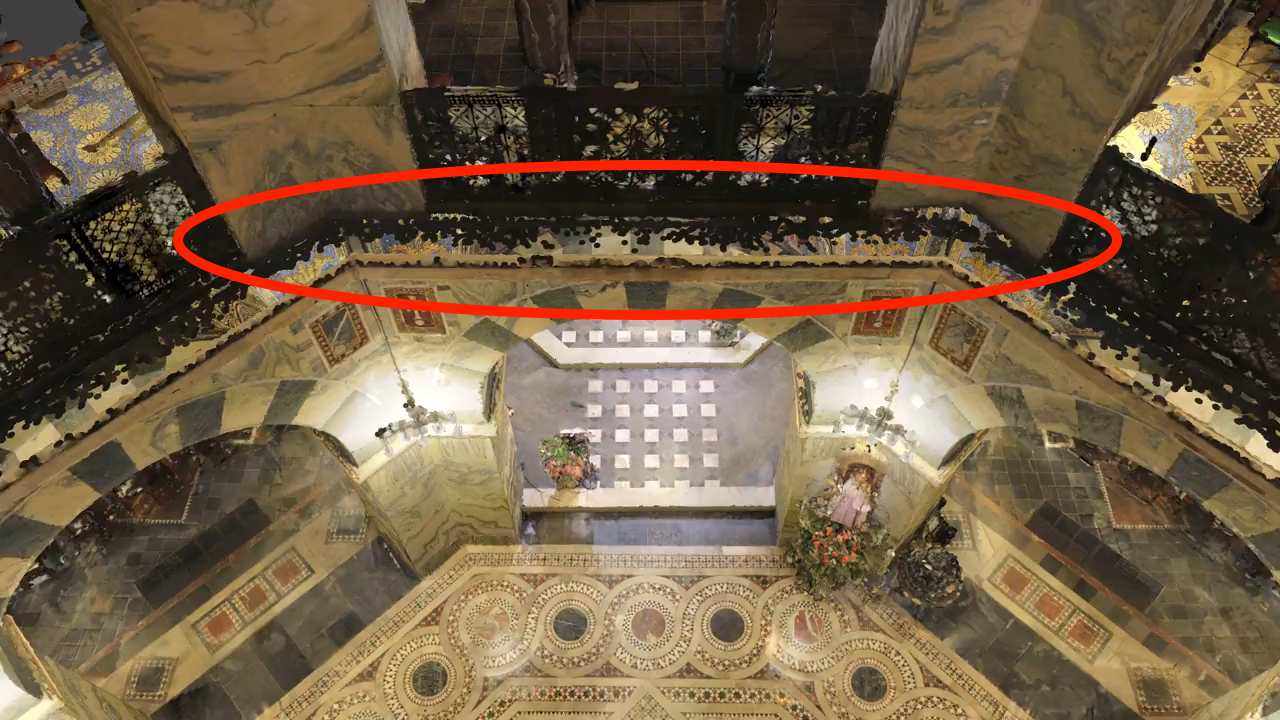

- Another major challenge: huge data sets!

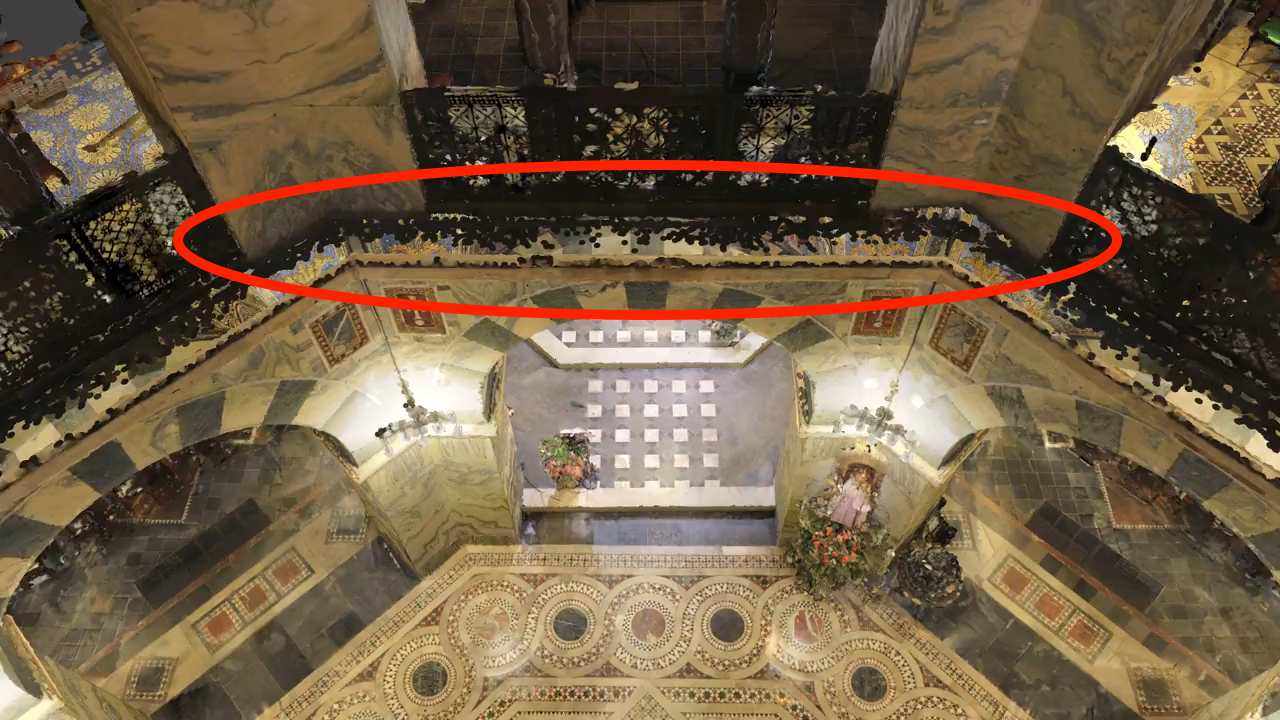

Aachen Dome

3D Scanning Techniques

3D Scanning Techniques

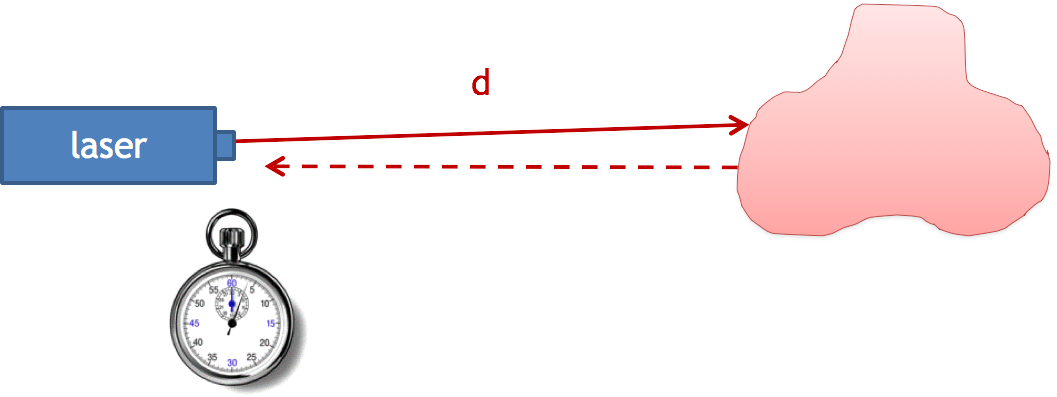

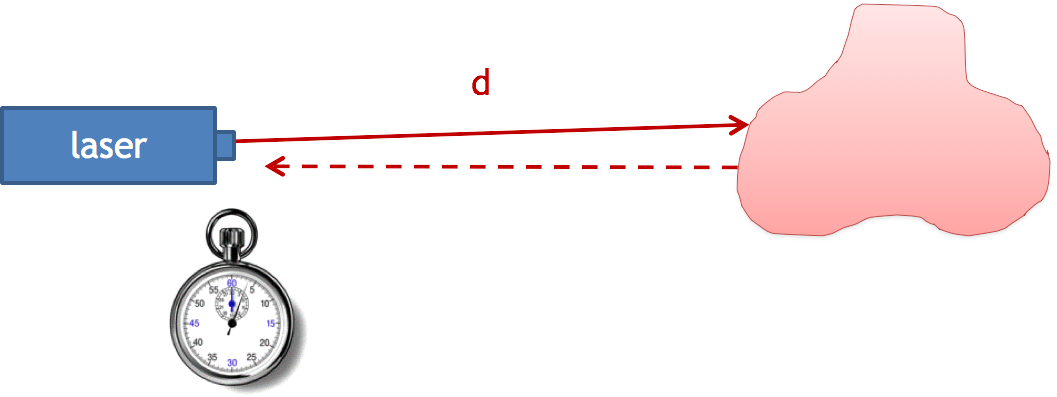

Time-of-Flight Scanners

- Probe object by laser or infrared light

- Emit pulse of light and measure the time until the reflection from the surface is “seen” by a detector

- Speed of light & measured round-trip time ==> distance to surface

Time-of-Flight Scanners

- Capturing a full surface

- Sweep beam over the surface, or

- Use time-of-flight camera

- High speed of light makes accurate measurement difficult

SwissRanger by Mesa

SwissRanger by Mesa  Kinect One

Kinect One

Time-of-Flight Scanners

- Laser LIDAR

- Light Detection and Ranging

- Good for long distance scans

- 6mm accuracy at 50m distance

Forecast 3D Laser System

Forecast 3D Laser System

3D Scanning Techniques

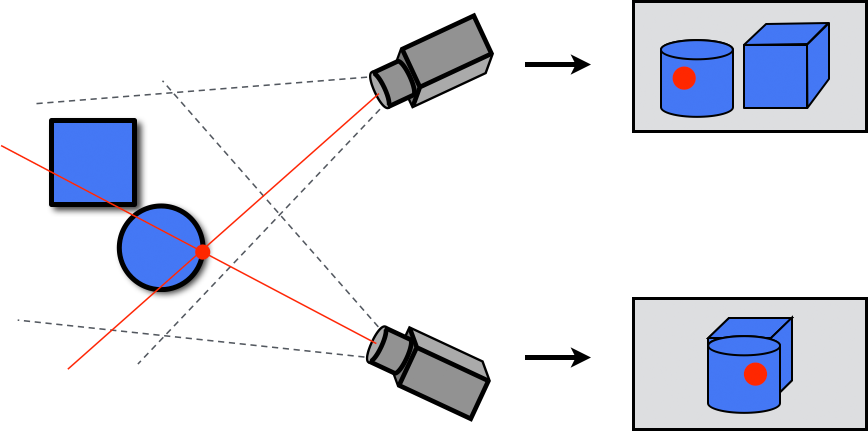

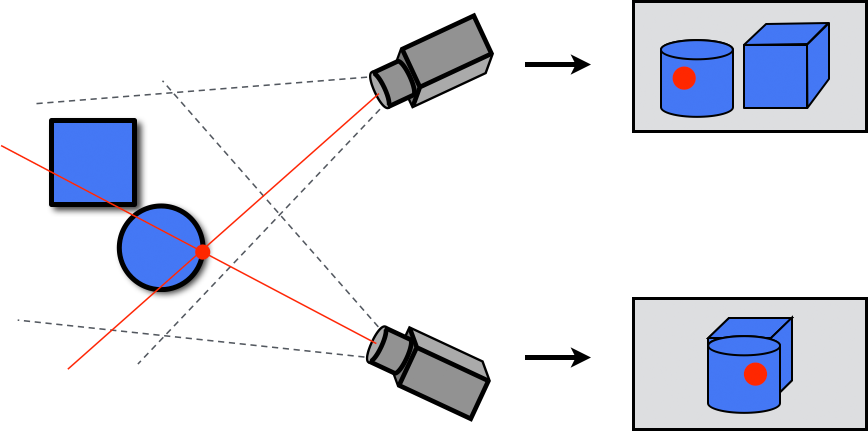

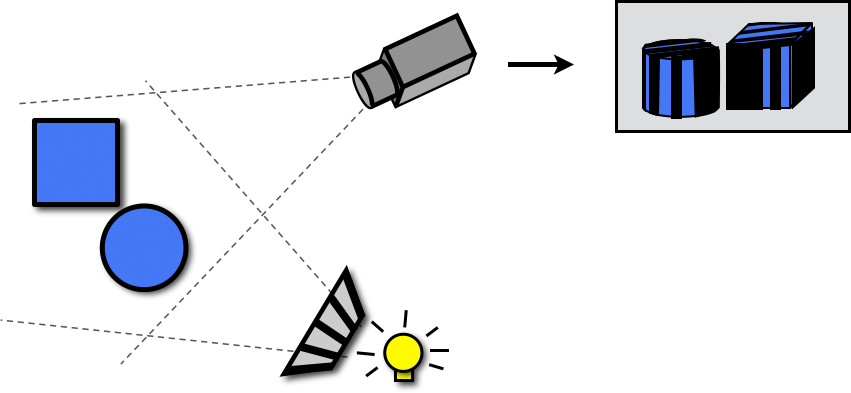

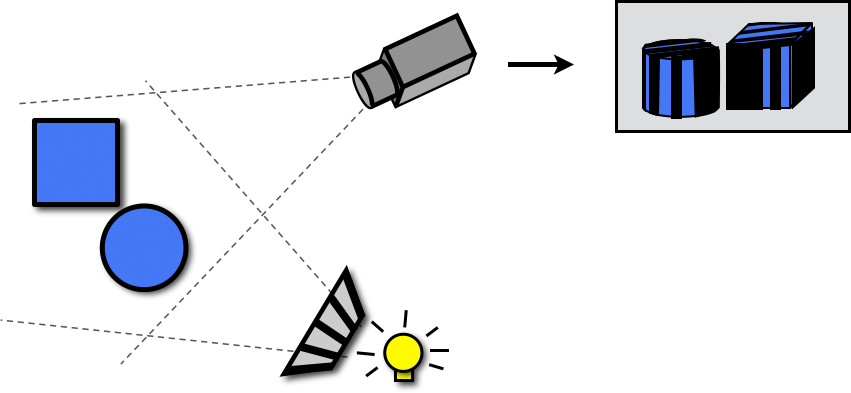

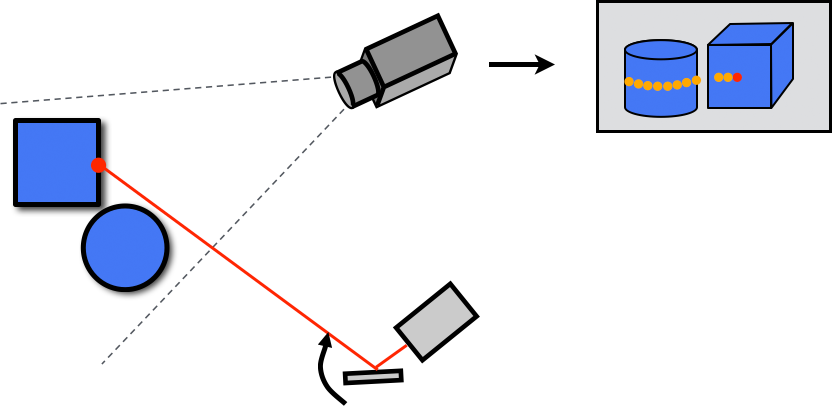

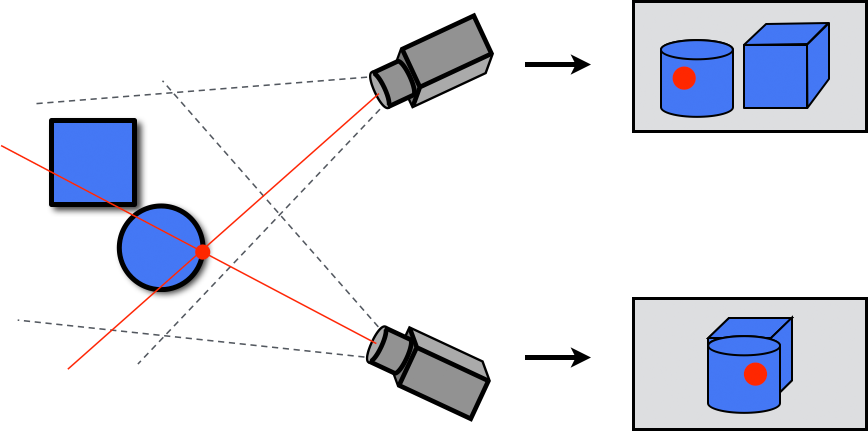

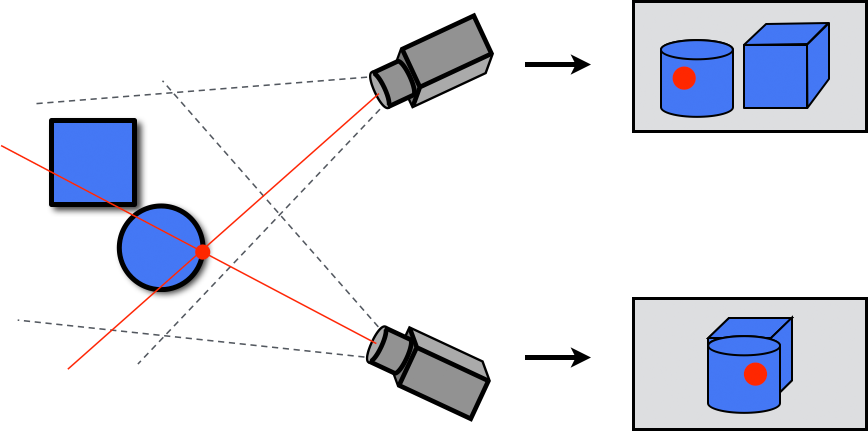

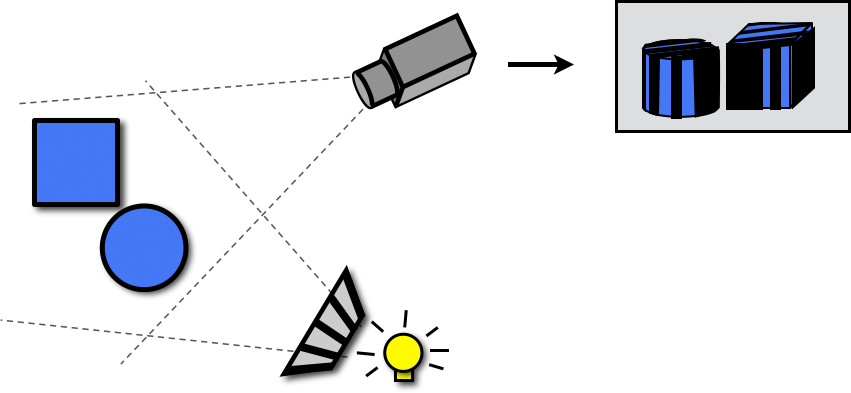

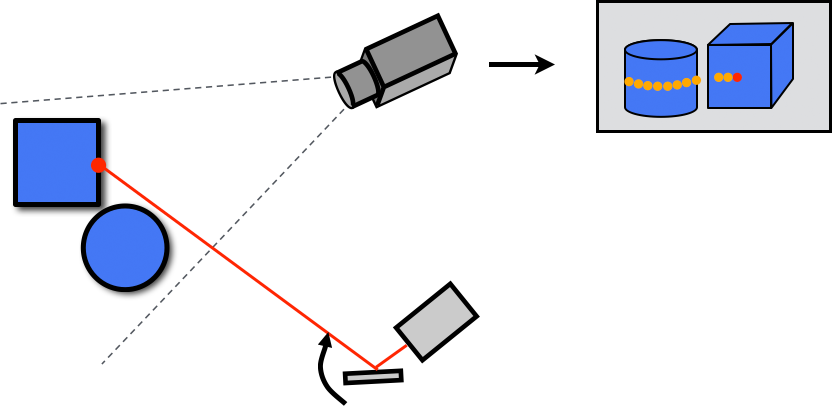

Triangulation Principle

- Two “cameras” identify the same 3D point

- Compute depth from angles and baseline

Triangulation Principle

- Two “cameras” identify the same 3D point

- Compute depth from angles and baseline

- Passive Stereo Matching

- Find and match features in both images

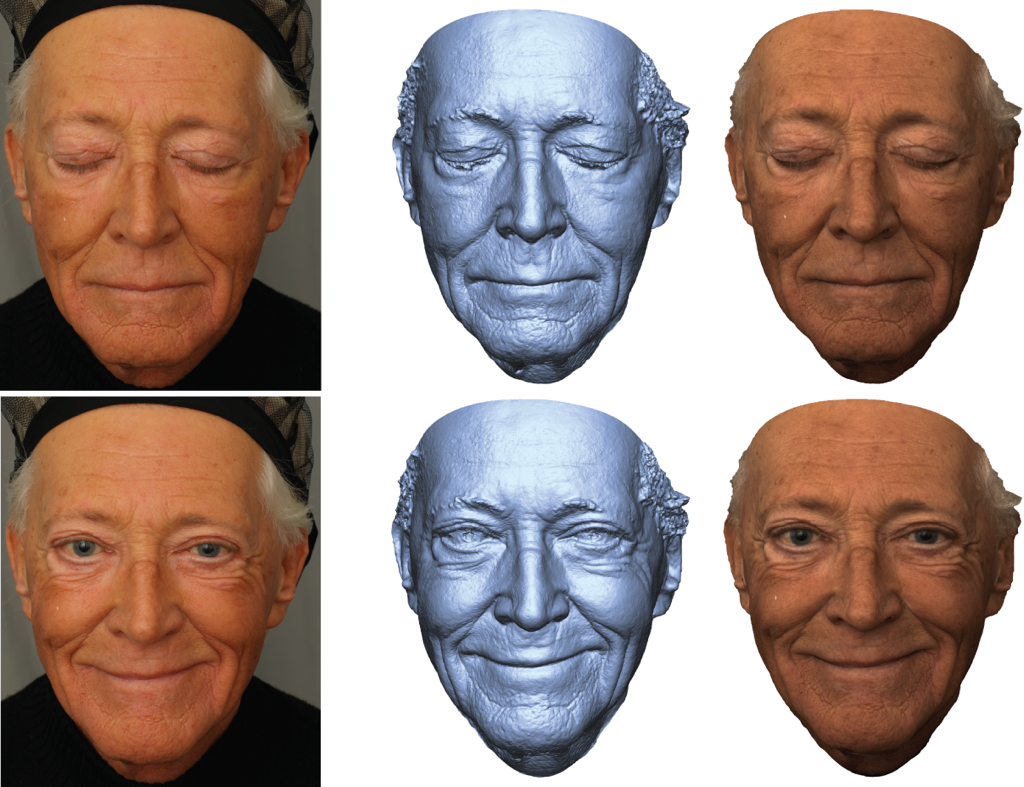

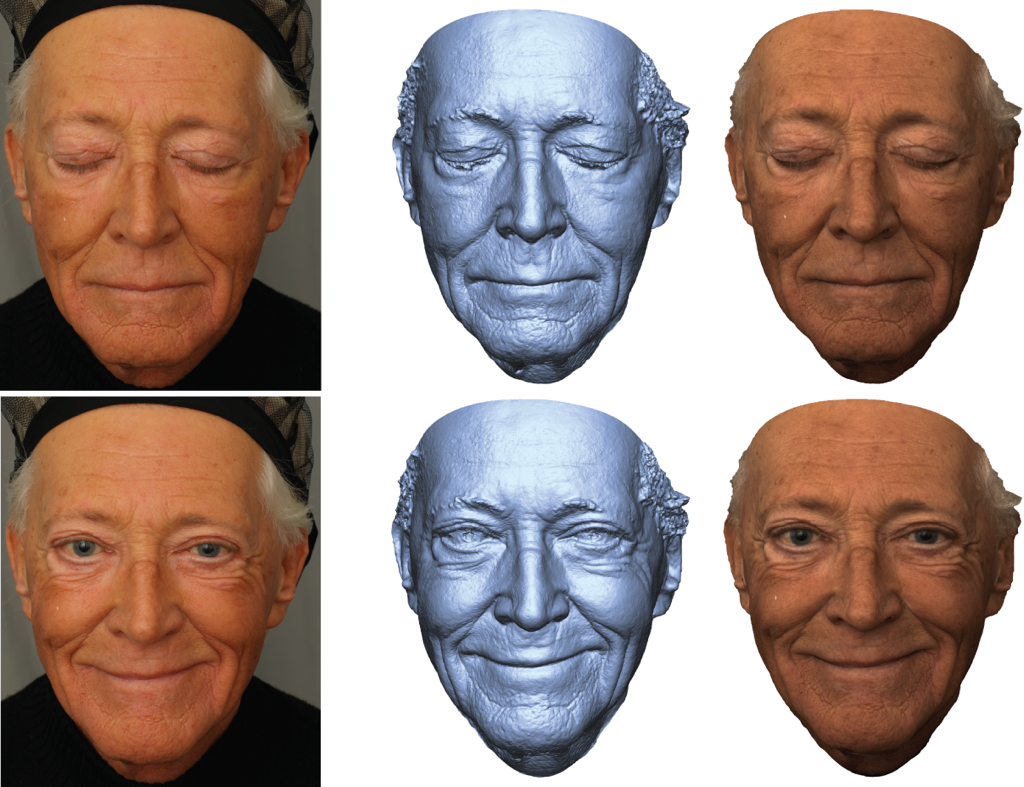

Passive Stereo Matching

- With high resolution cameras, skin has a lot of details!

Passive Stereo Matching

- Passive stereo capturing is fast (just one shot)

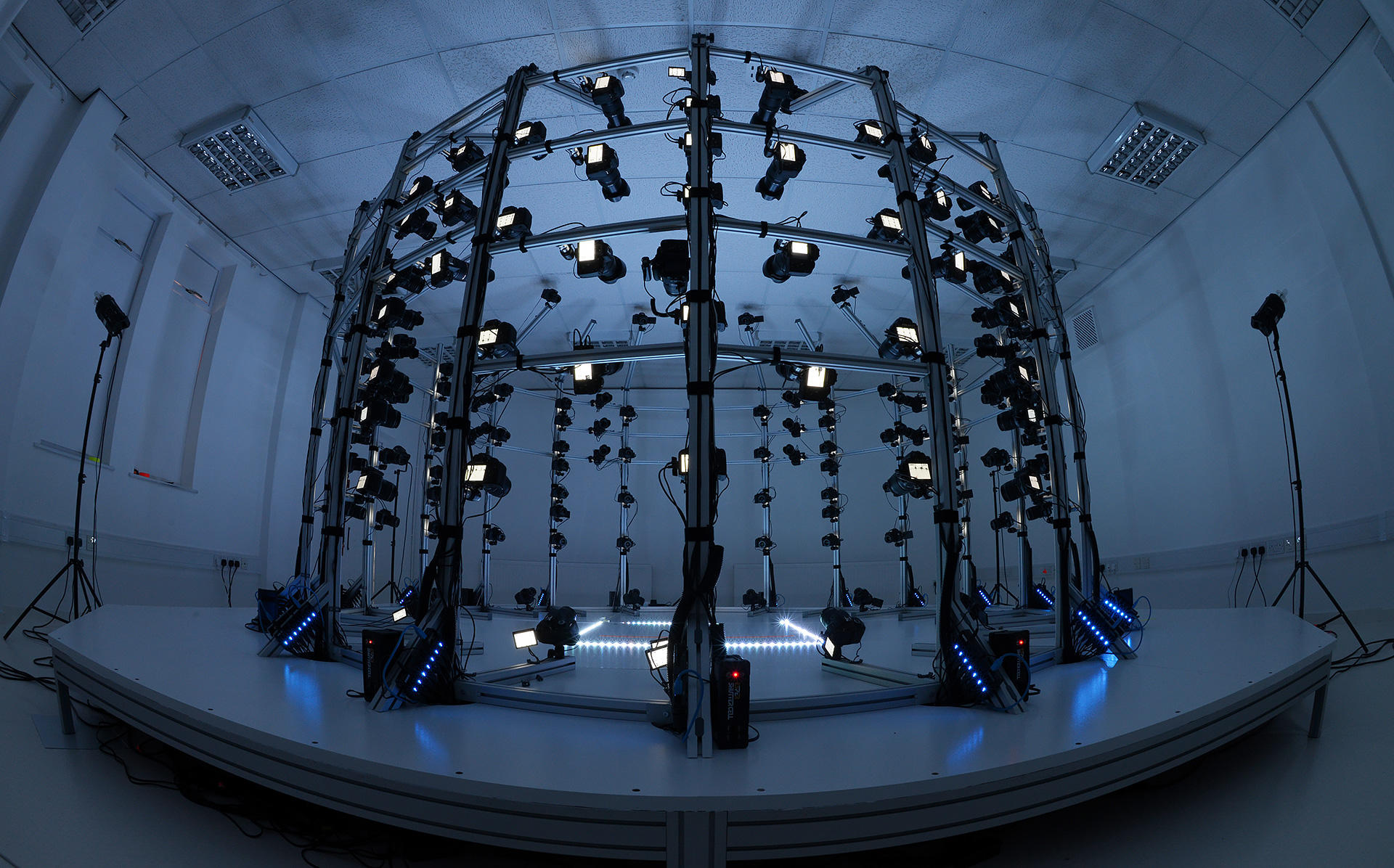

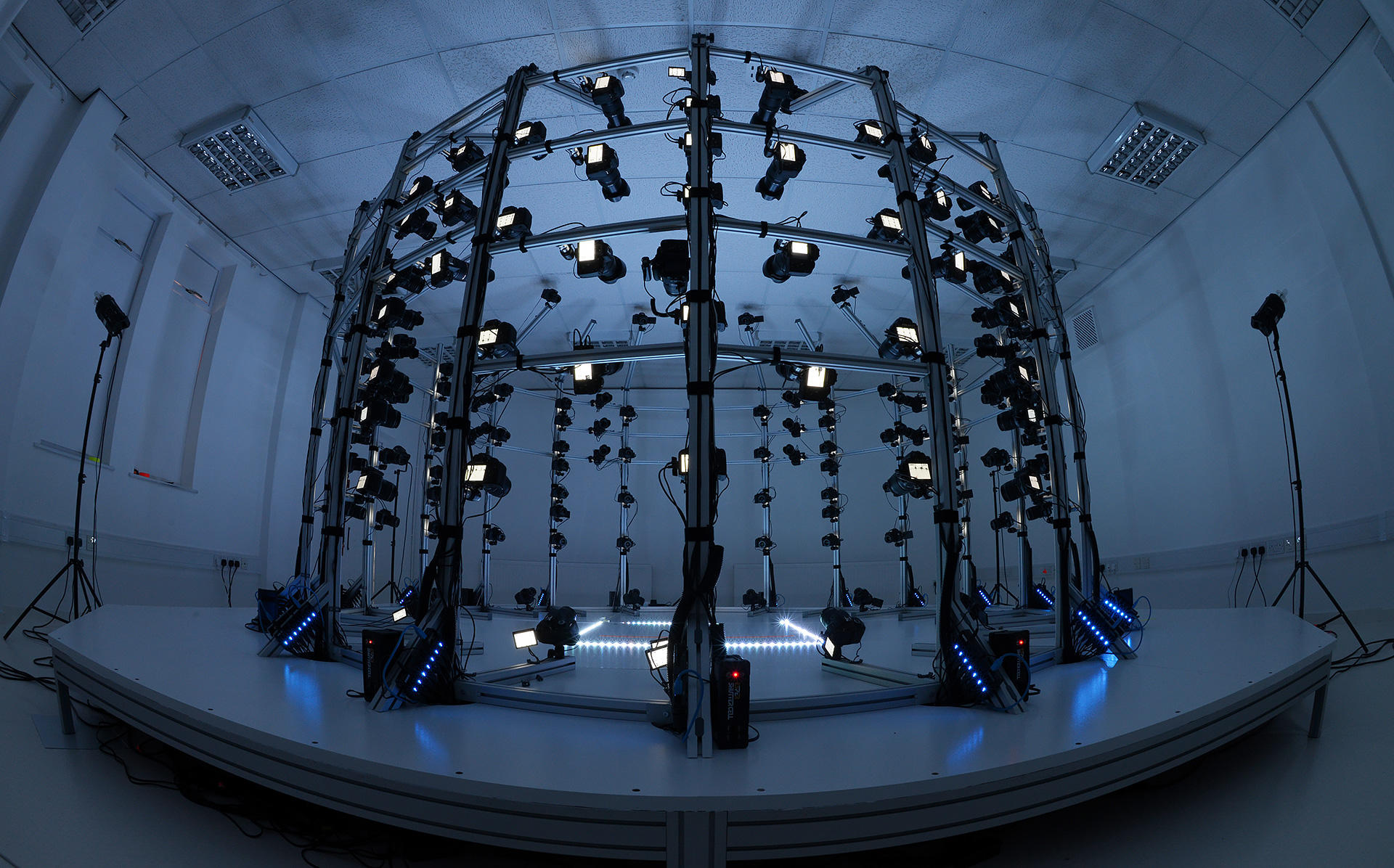

Ten24 Face Scanning

Ten24 Face Scanning

- More than two cameras!

- Same triangulation principle: one camera pair at a time.

Multi-view Stereo

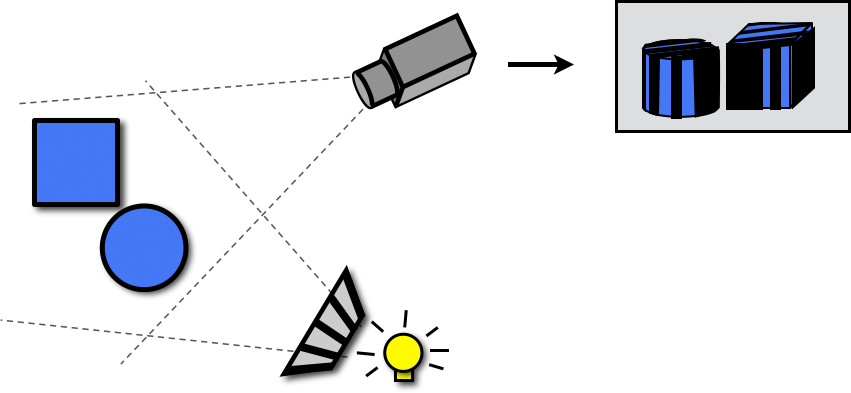

3D Scanning Techniques

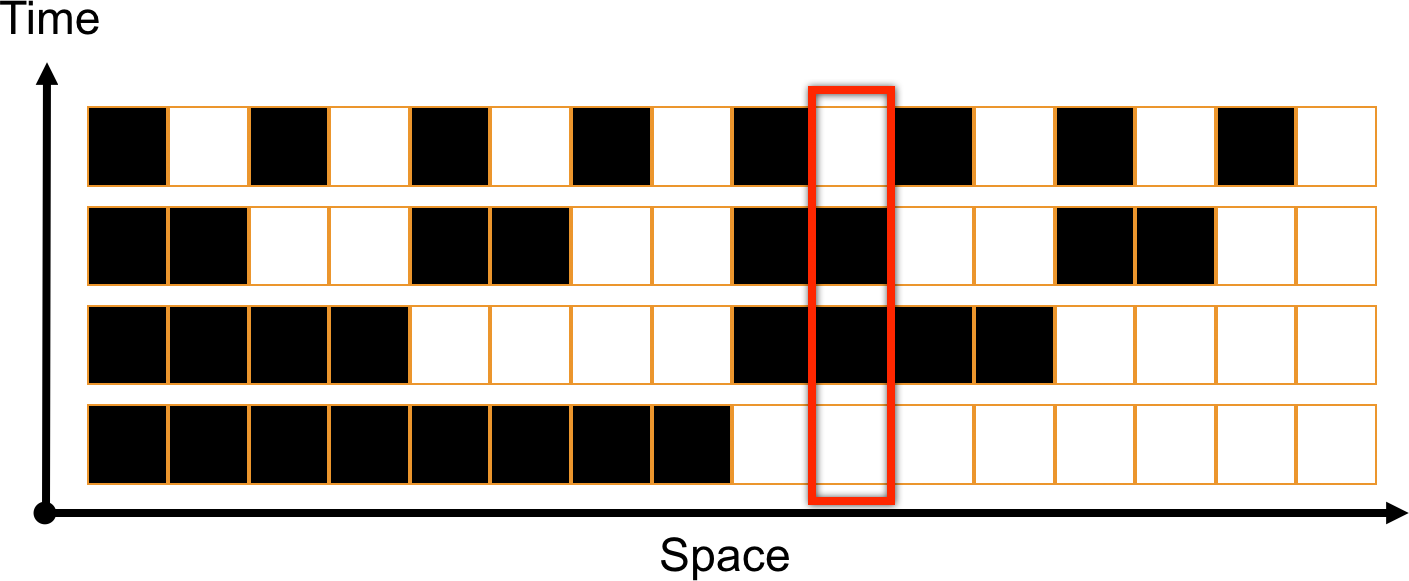

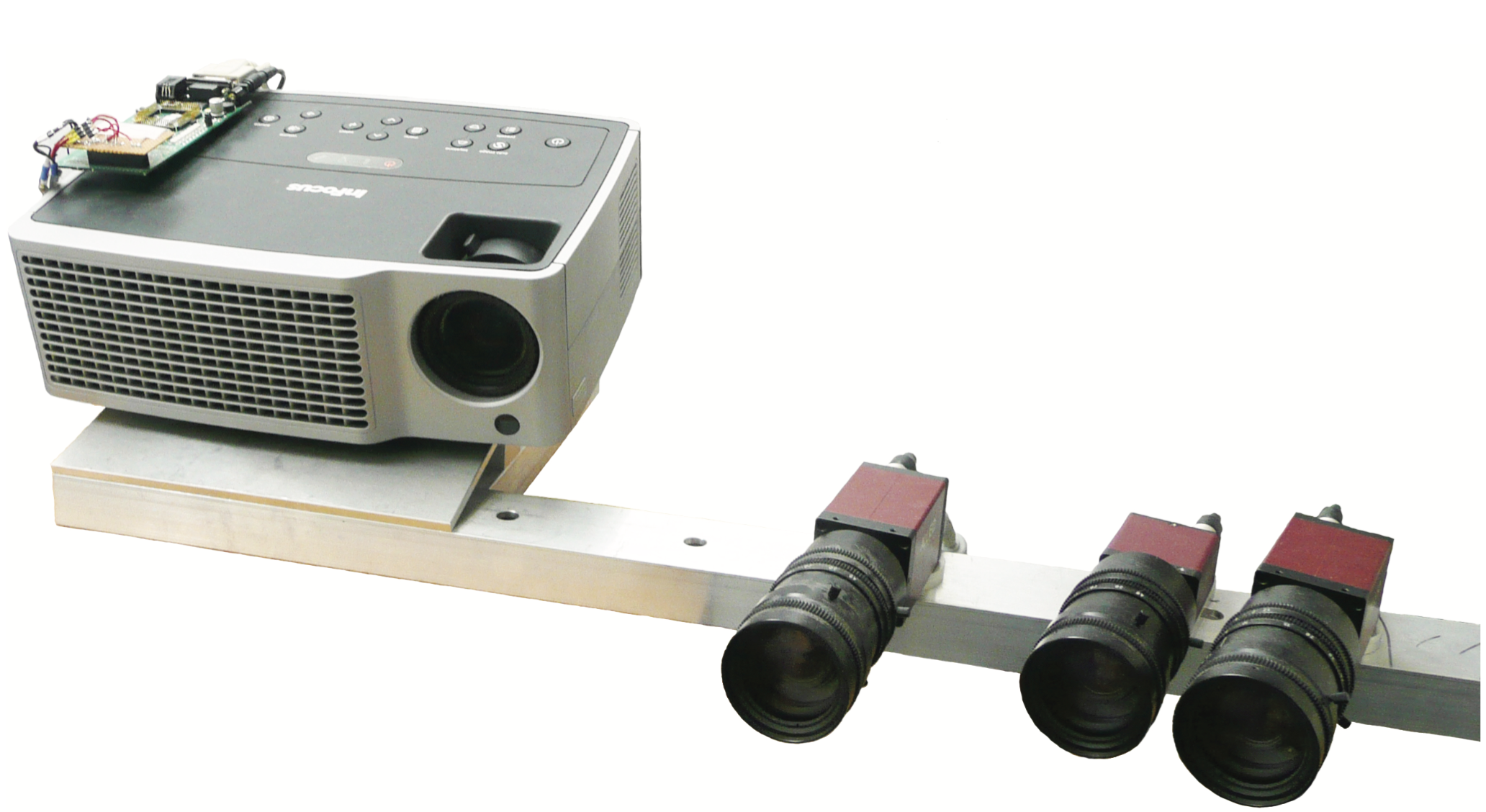

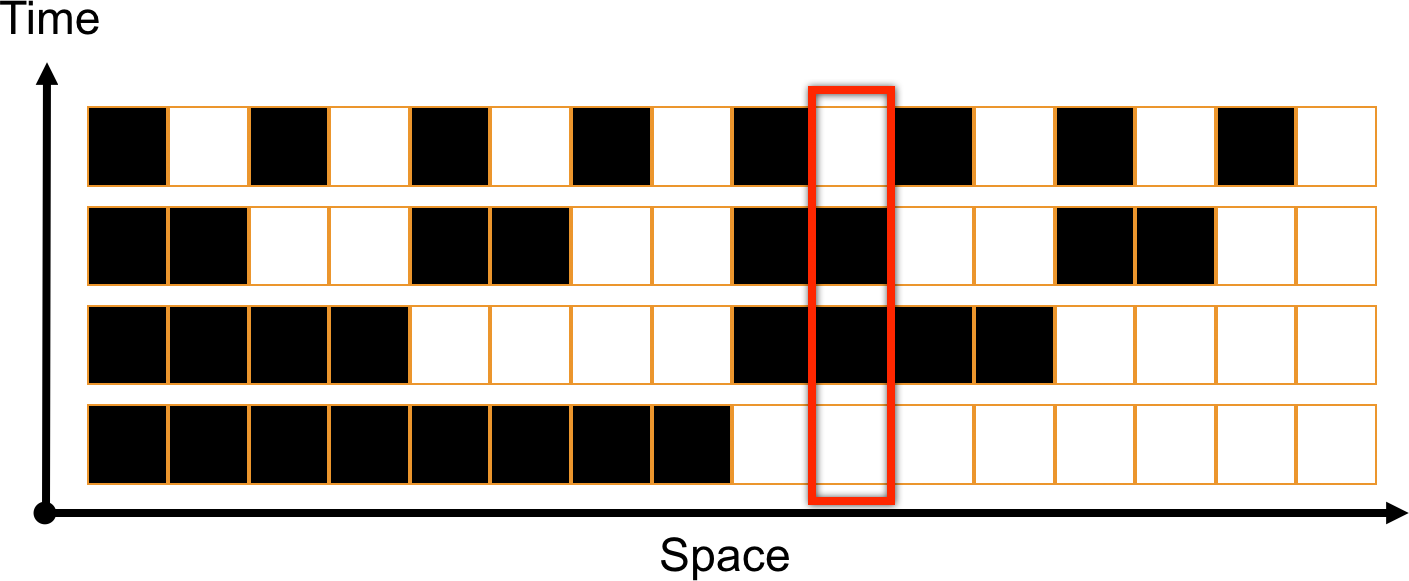

Structured Light Scanner

- 1 camera and 1 projector

- Project special patterns to identify pixels

Structured Light Scanner

- 1 camera and 1 projector

- Project special patterns to identify pixels

Structured Light Scanner

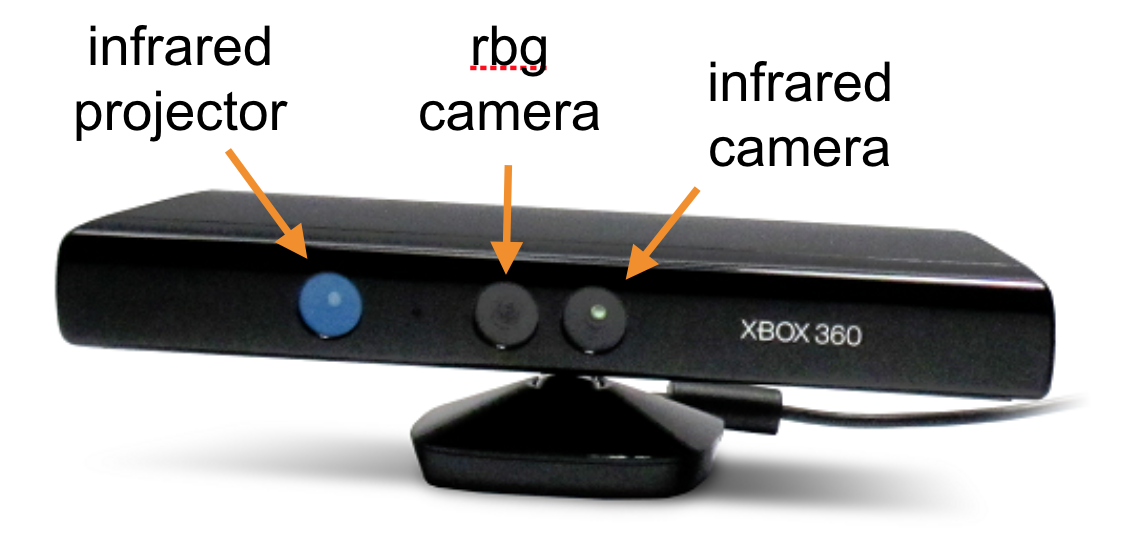

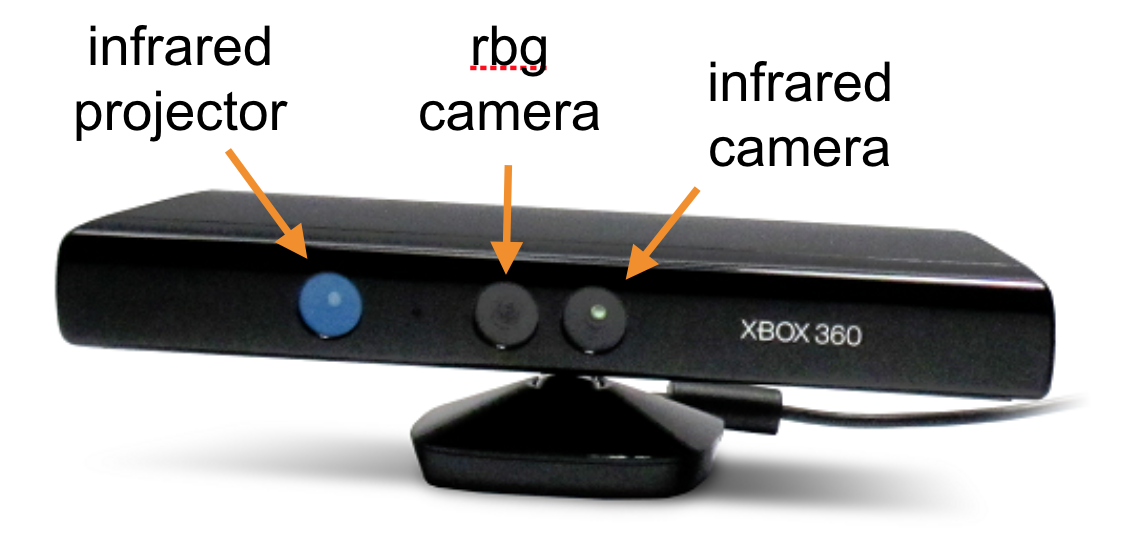

- Consumer-level scanner: e.g. Microsoft Kinect

- Project infrared pattern, but just one frame

- Fast (30fps), but noisy data

infrared pattern

infrared pattern

[Denis John]

[Denis John]

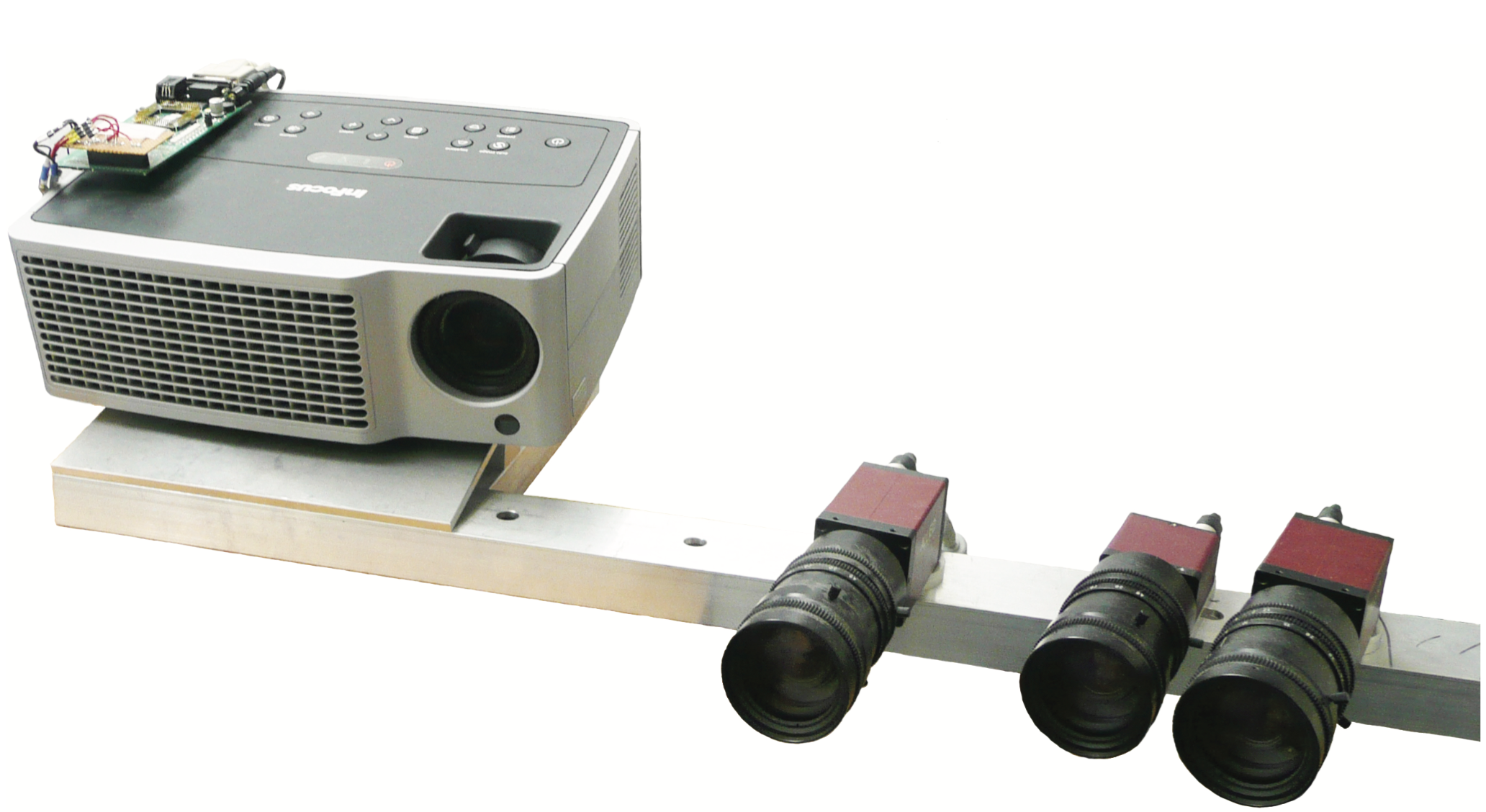

Structured Light Scanner

- Comparison to custom-built scanner (>$10k)

LGG Lab Scanner (2009)

Kinect (2011)

Aside: Face Tracking

LGG Research Prototype 2013

Aside: Face Tracking

LGG Spin-Off Company: Faceshift 2015

Aside: Face Tracking

Apple’s Animojis

Apple’s Animojis

FaceID

Apple’s FaceID

3D Scanning Techniques

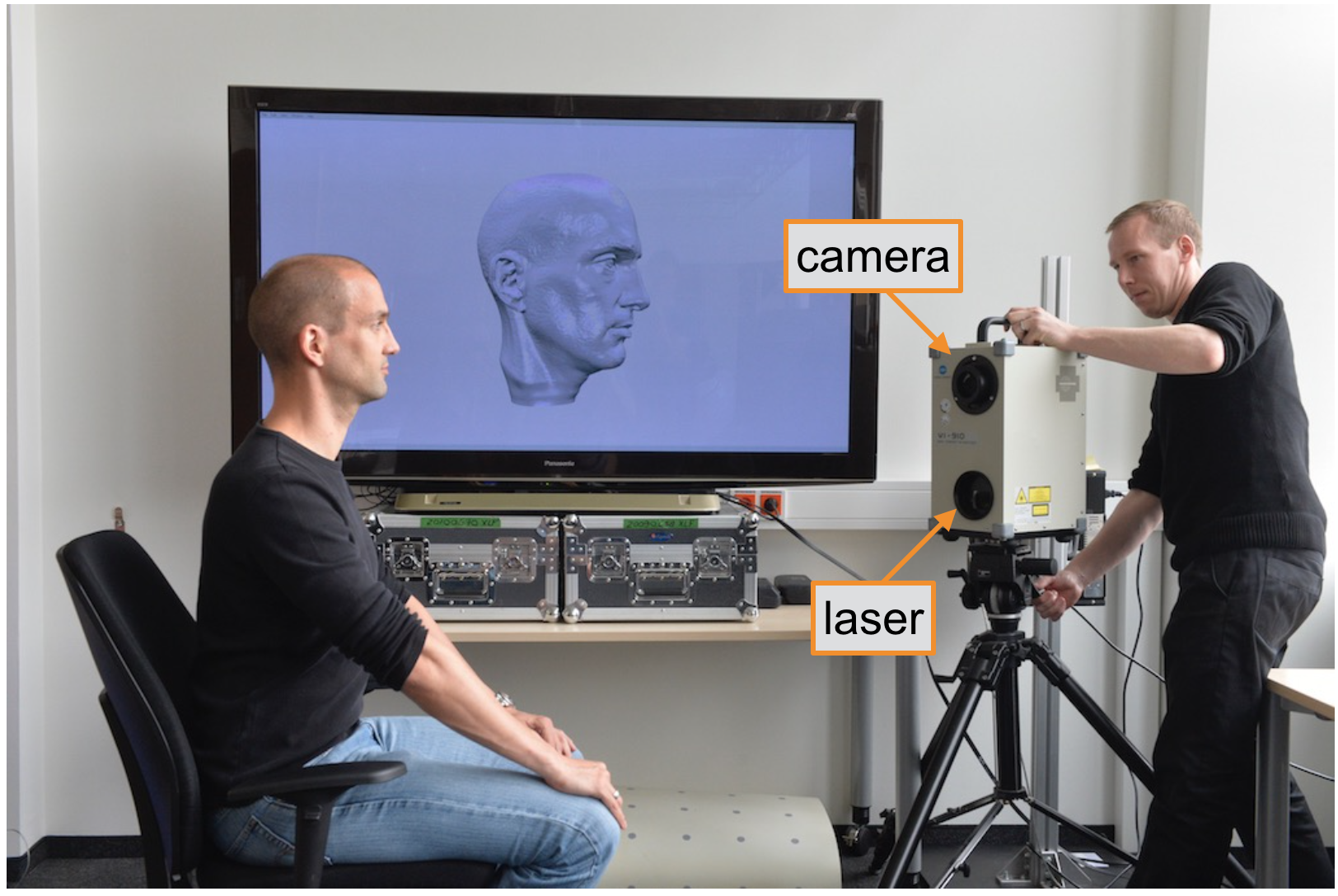

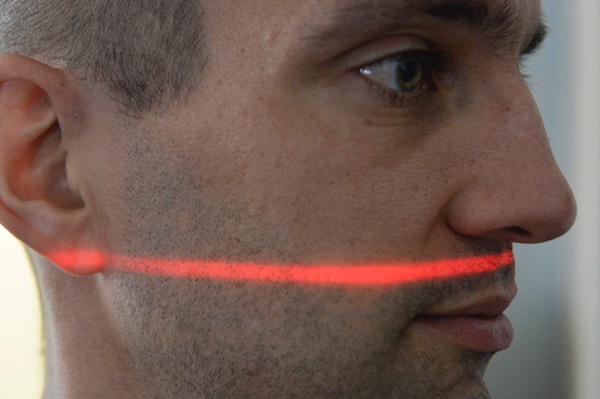

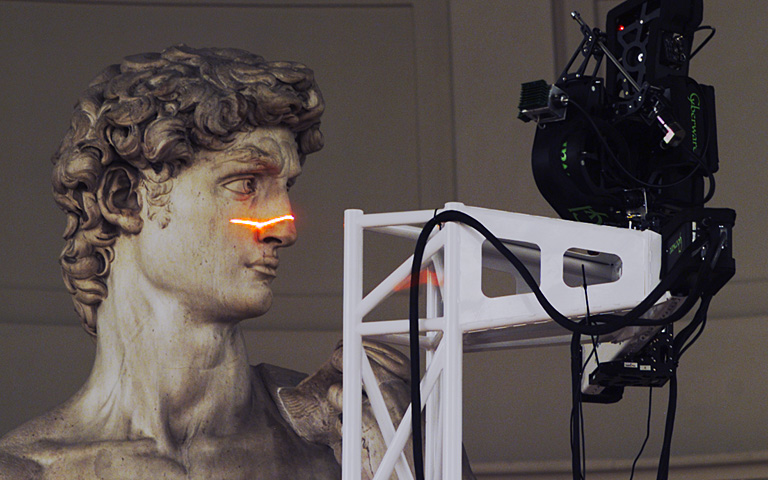

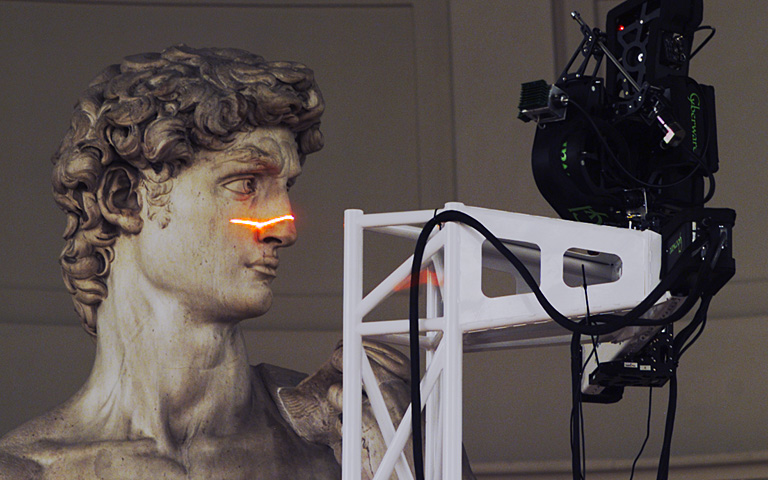

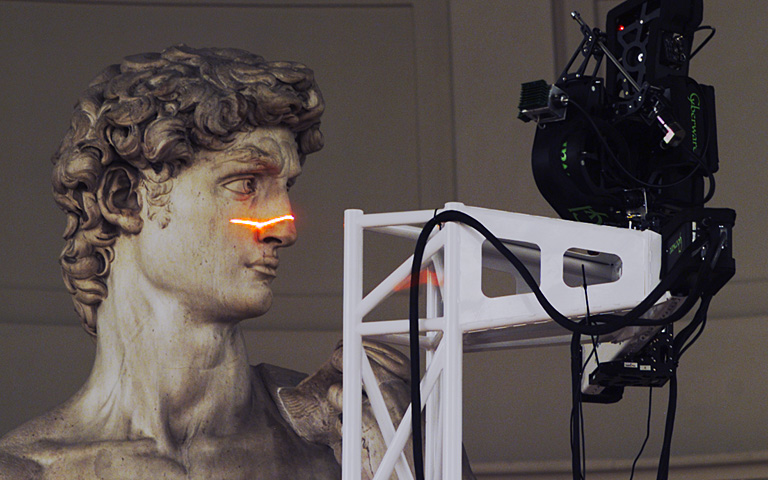

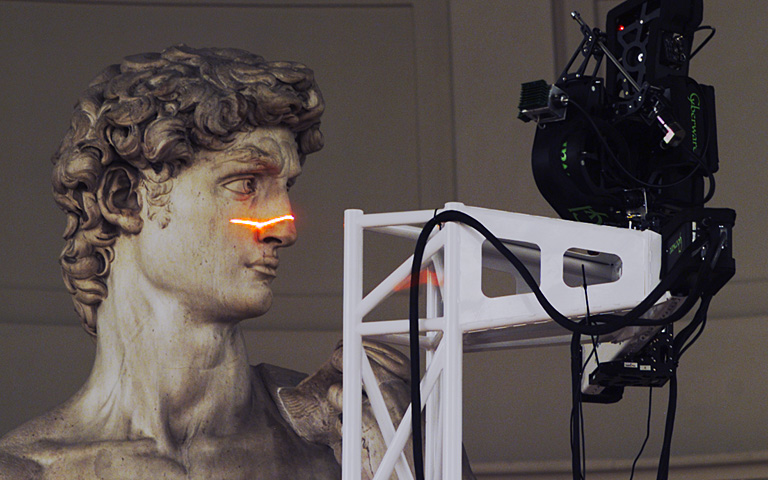

Laser Scanning

- 1 camera and 1 laser beam

- Sweep laser, identify laser in camera image

Digital Michelangelo Project

3D Scanning Techniques

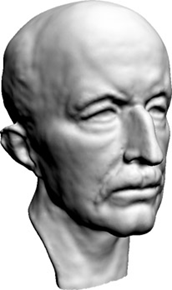

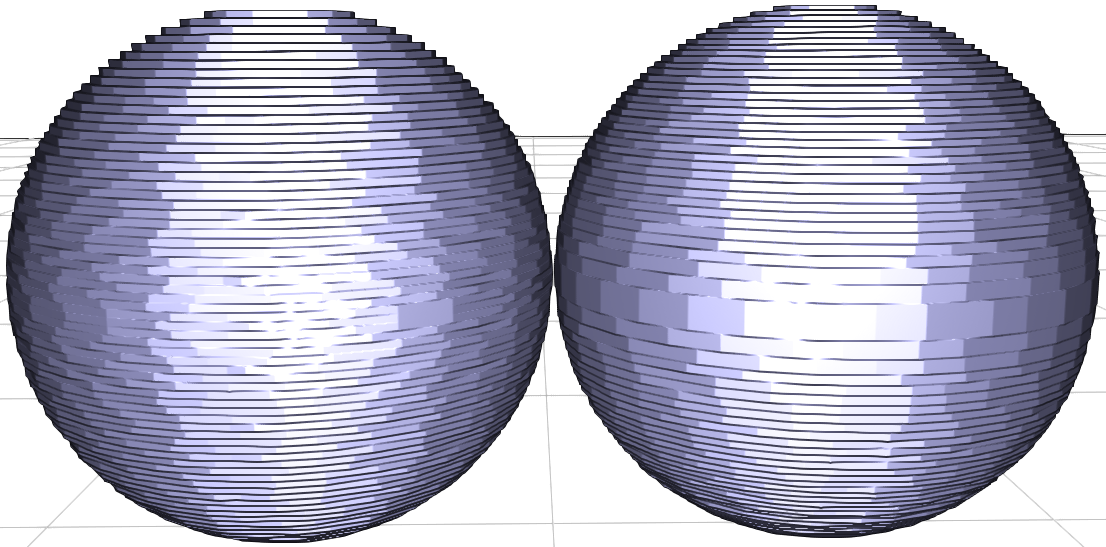

3D Scanner Data

- Common issues with scanned data:

- Noise (especially bad with structured light scanning) Kinect (2011)

3D Scanner Data

- Common issues with scanned data:

- Noise (especially bad with structured light scanning)

- Holes

3D Scanner Data

- Common issues with scanned data:

- Noise (especially bad with structured light scanning)

- Holes

- Insufficient resolution

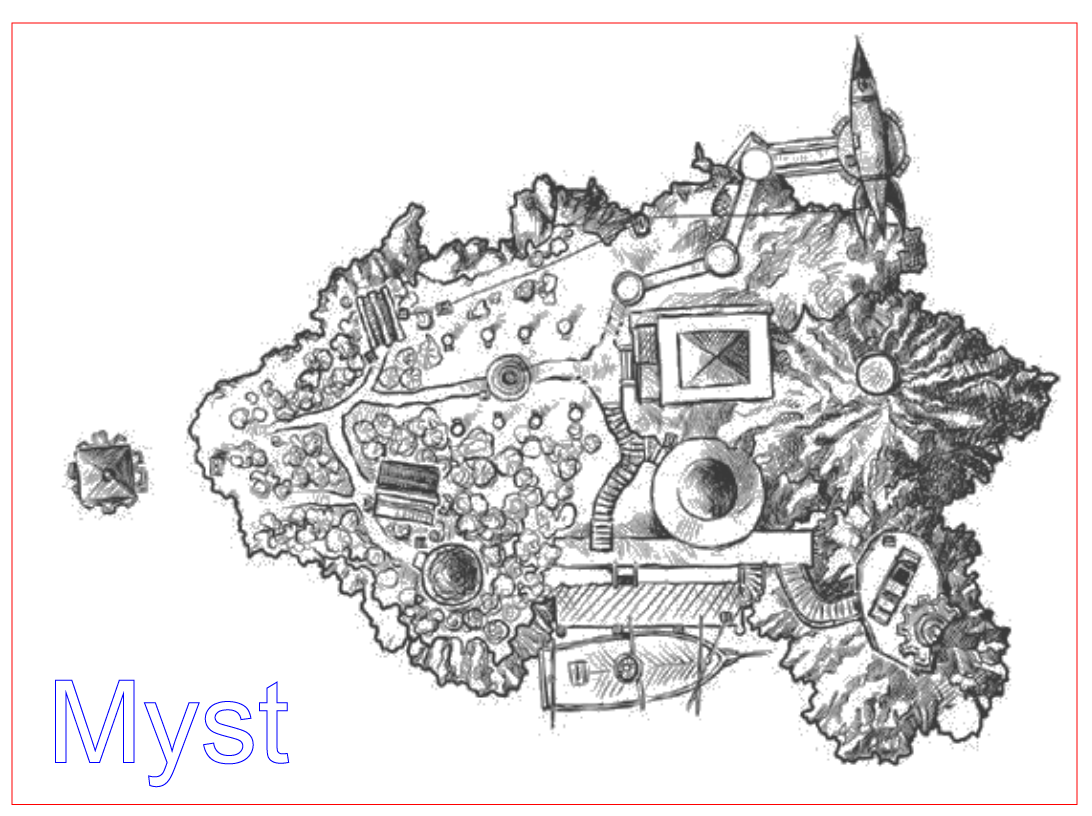

3D Content Creation Pipeline

Digital fabrication: bringing digital geometry to the physical world

- Fabrication technologies

- Subtractive

- Laser cutting

- CNC (computer numerical control) turning/milling

- Additive

- Designing parts for 3d printing

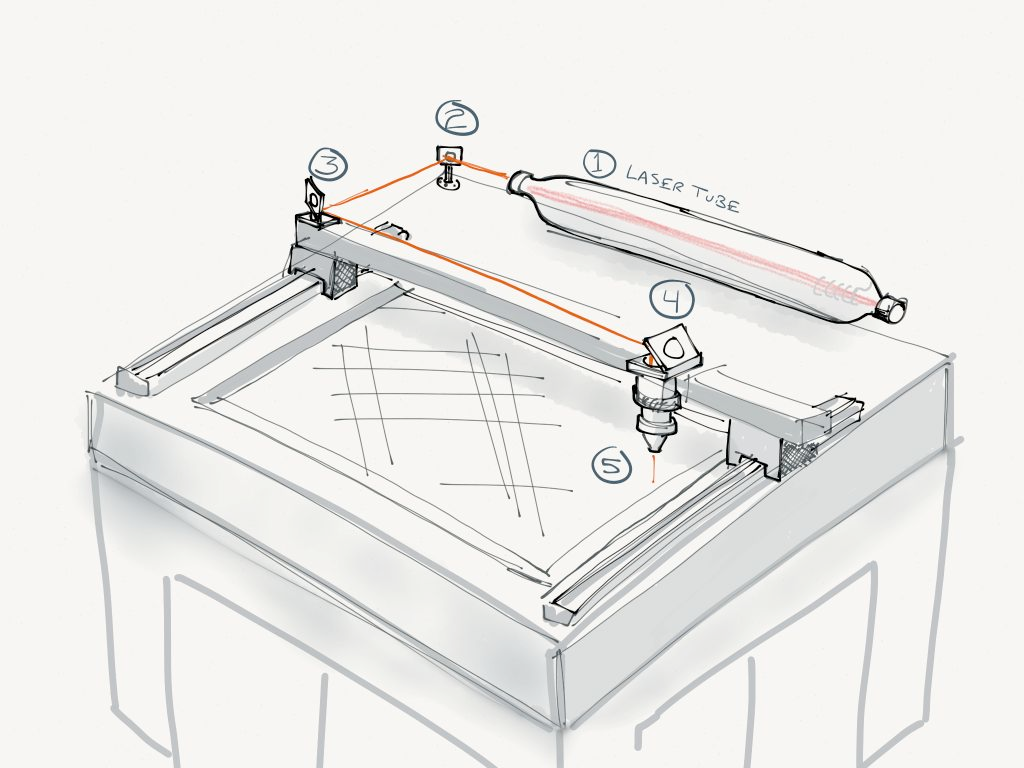

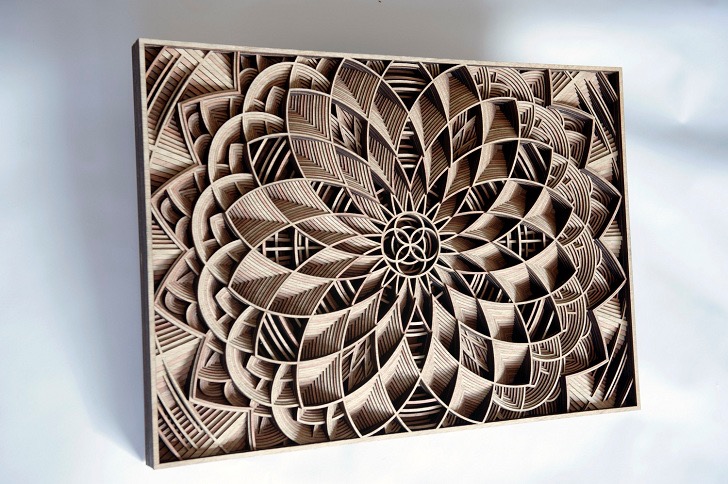

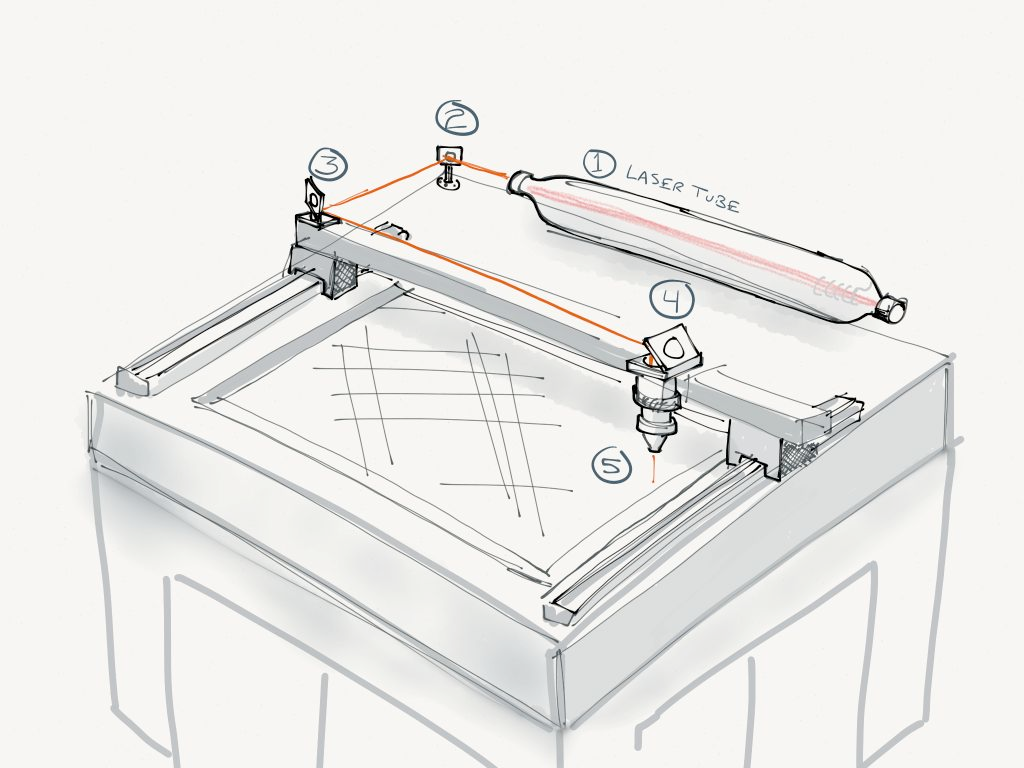

Laser cutting

- Cut/engrave flat sheets with a laser

- Supports many materials (wood, metal, paper, acrylic, …)

Laser cutting

Laser cutting: how it works

- Mirrors direct laser beam to precise (x, y) location

- Laser intensity/exposure time tuned for the material and desired effect (cutting vs engraving)

Laser cutting

Laser cutting: from file to object

- Design is just an image; mode chosen by color:

vector cutting, vector engraving, raster engraving

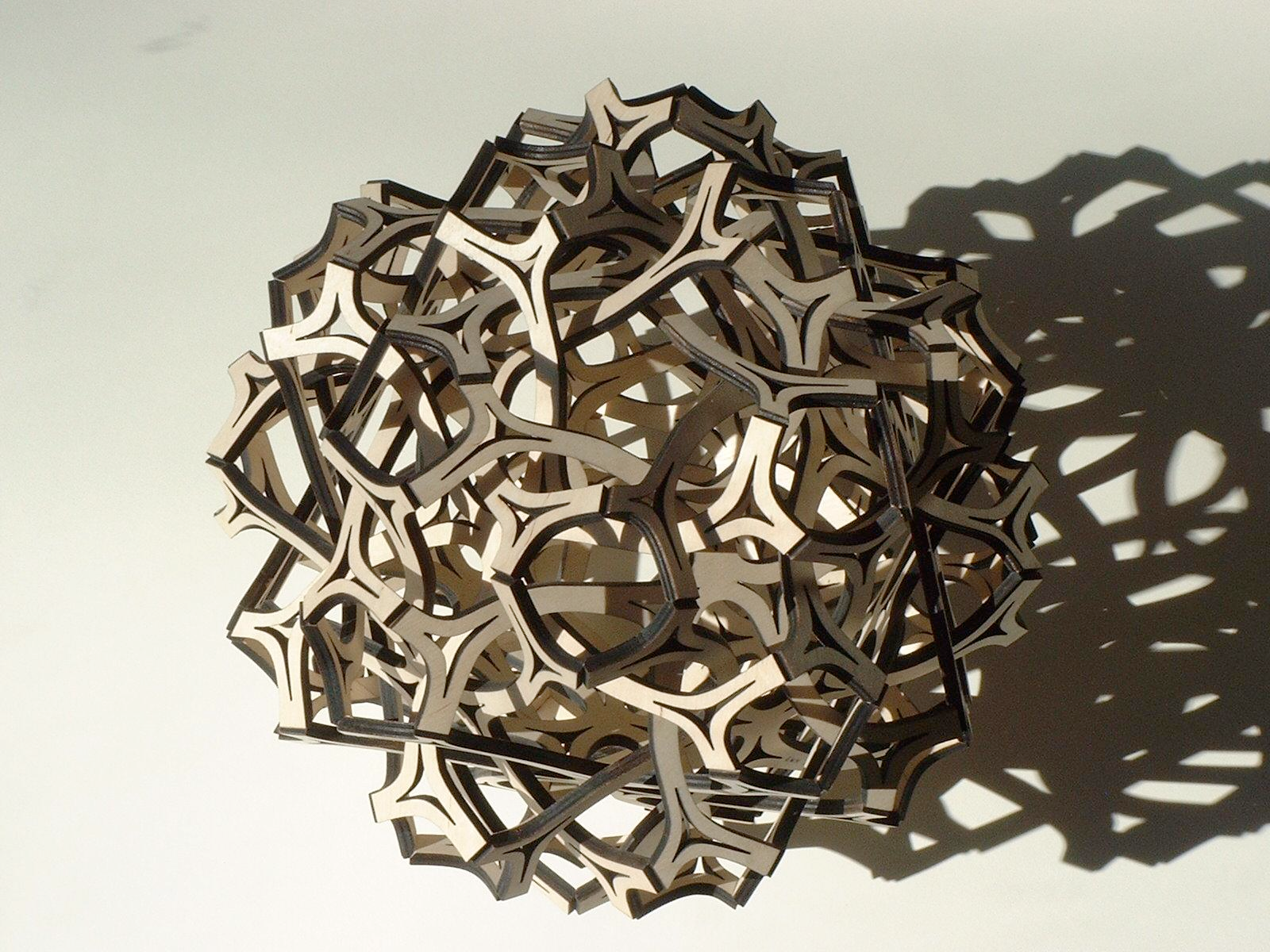

Laser cutting

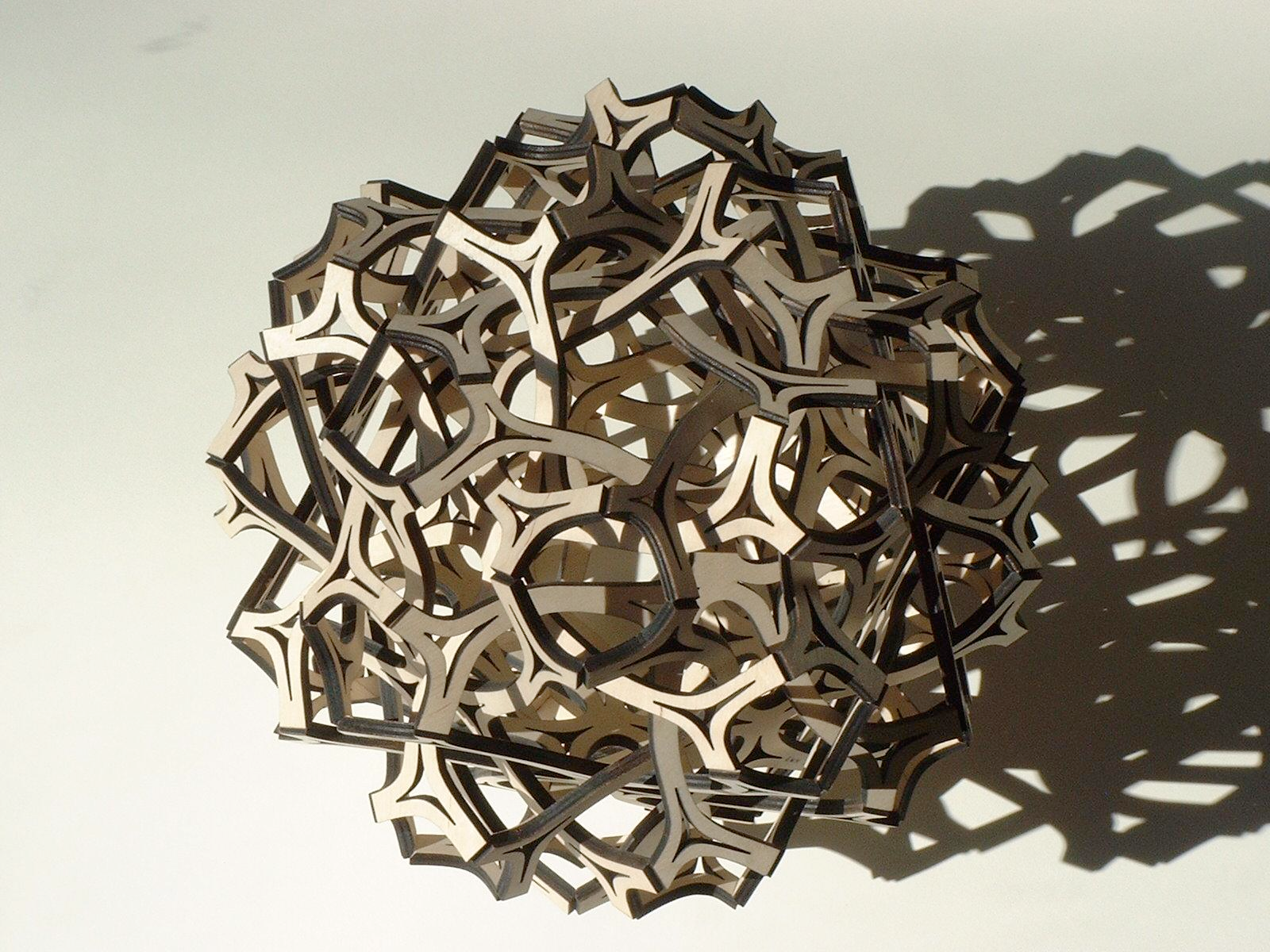

- Great for fabricating 2D or 2.5D designs

- Can also produce 3D shapes:

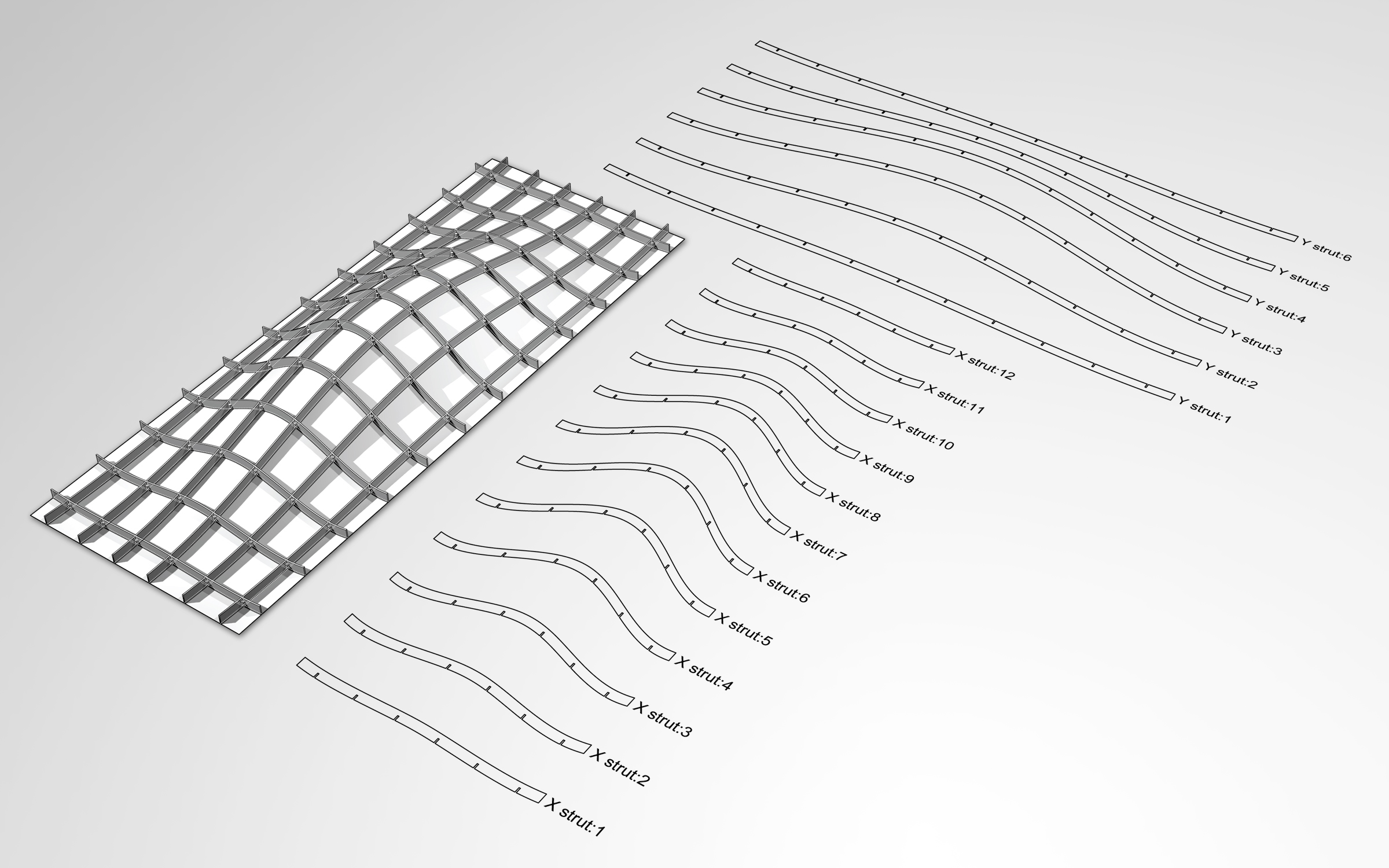

Laser cutting: designing sliced parts

Rhino/Grasshopper

Laser cutting: 3D shapes by folding

Pepakura Designer

Laser cutting: curved surfaces

- Sheet metal/paper only bend into developable surfaces

(Gaussian curvature K = 0)

- Inserting cuts enables stretching, permitting nonzero K

Beyond Developable: Konakovic et al. 2016

CNC turning (lathes)

- Rapidly spin material, insert cutting tool

- Great for surfaces of revolution, screw threads, etc.

Glacern Machine Tools - YouTube

CNC milling

- Rotating cutter, complex insertion paths (5-axis)

- Produce much more general 3D shapes

CNC milling: advantages

- Great accuracy

- Large parts

- Great mechanical properties:

part is solid material, not built from slices

CNC milling: limitations

Wasteful: material milled away is lost

Geometry limitations:

cutting tool must reach all surfaces

Planning tool paths/selecting cutting tools can be challenging

- Higher fixed-costs

- Slower turnaround time

Usually large, expensive and dangerous

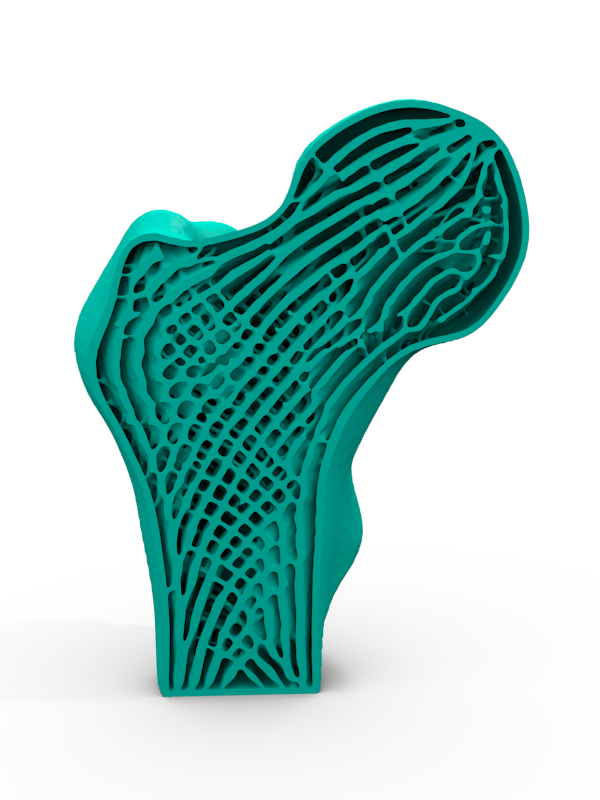

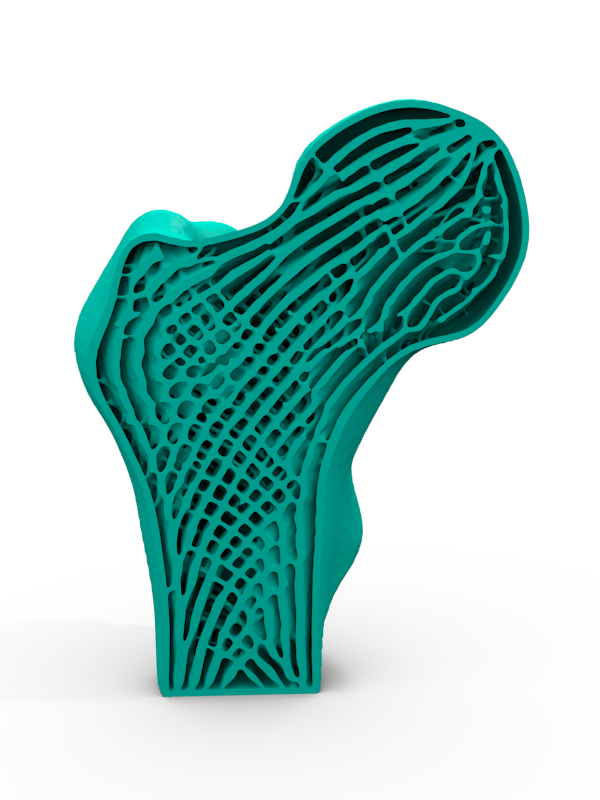

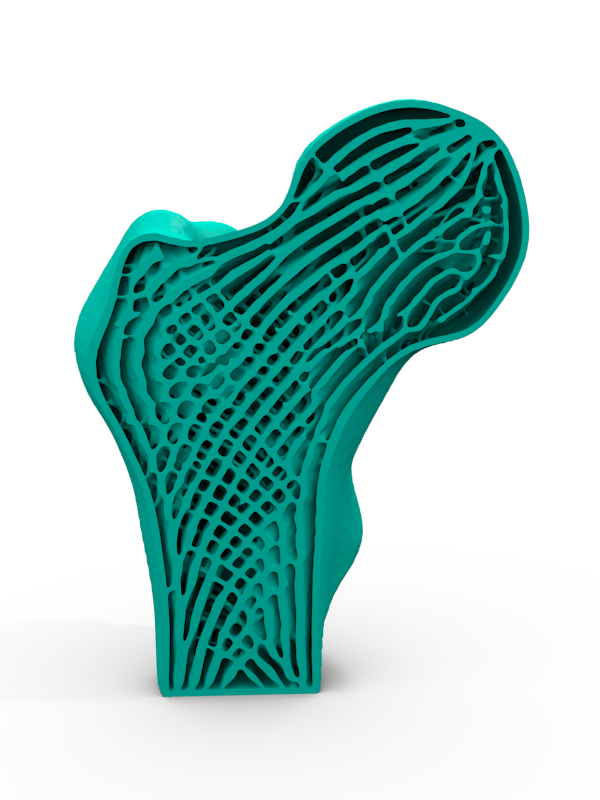

Infill Optimization: Wu et al. 2017

Infill Optimization: Wu et al. 2017

Desktop CNC milling

Pocket NC Version 2 - YouTube

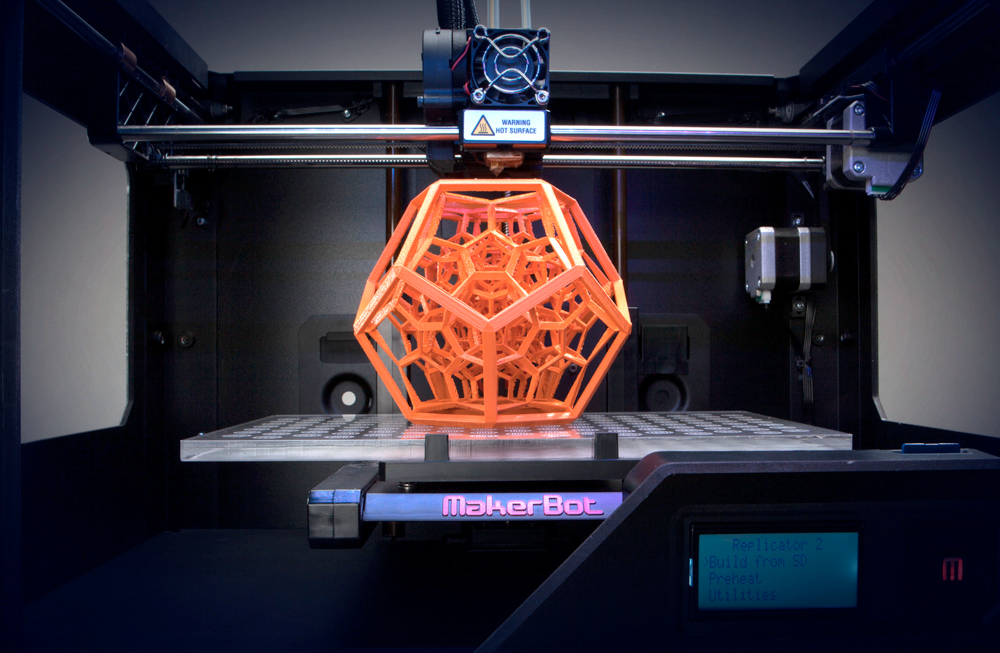

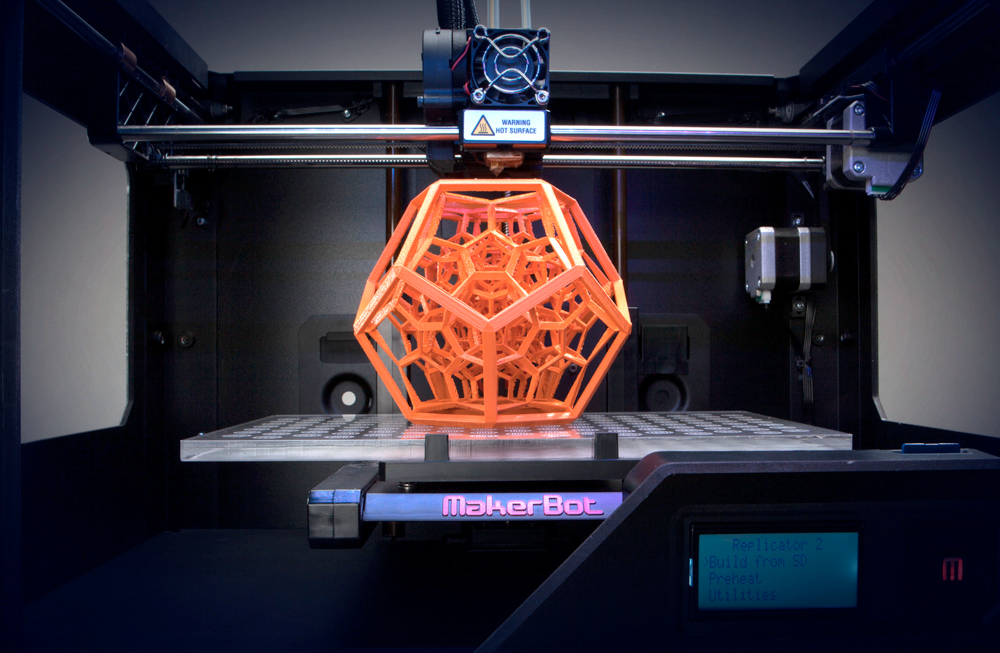

3D printing

- Slice 3D object into many layers

- Fabricate layers one at a time, from bottom to top

3D printing: advantages

- Pay only for the material you use

- Material isn’t wasted like in CNC milling

- Cost and fabrication time independent of complexity

- Objects with highly complex topology can be fabricated

- “Just click print”

- Less complicated planning process than CNC

- Shorter turn-around time

Infill Optimization: Wu et al. 2017

Infill Optimization: Wu et al. 2017

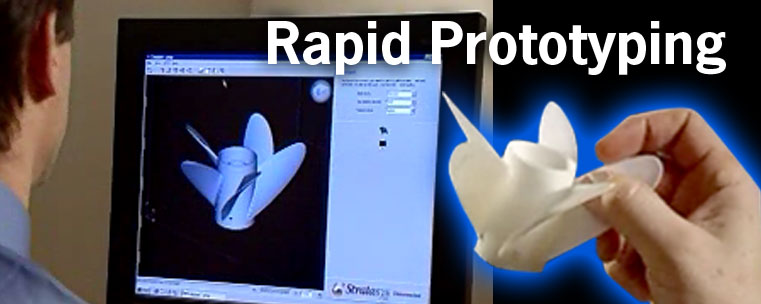

Applications: industrial design

Rensselaer Polytechnic Institute

Rensselaer Polytechnic Institute

Applications: customized products

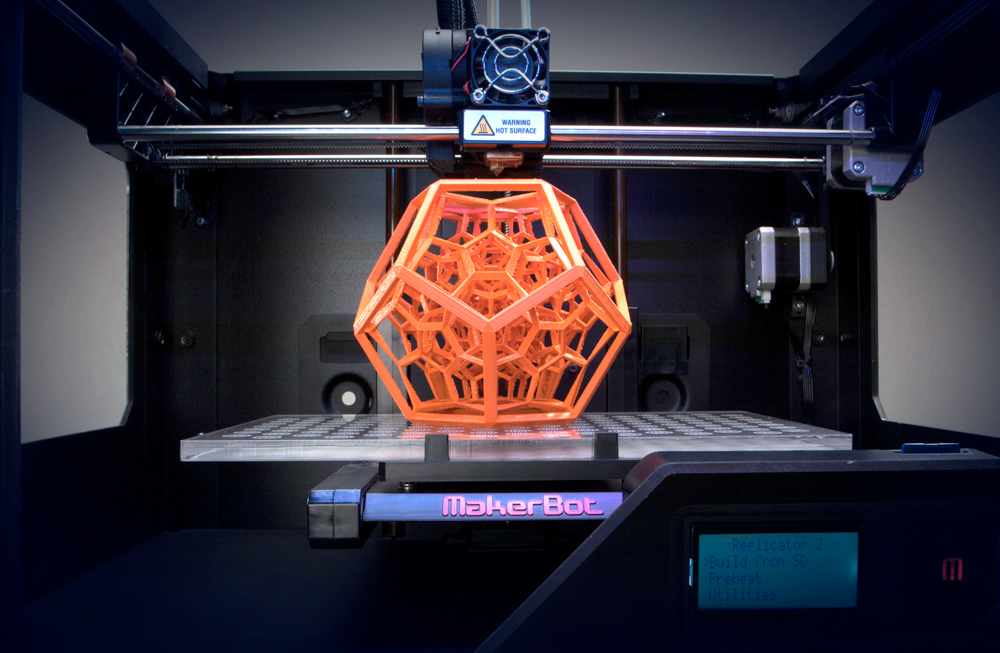

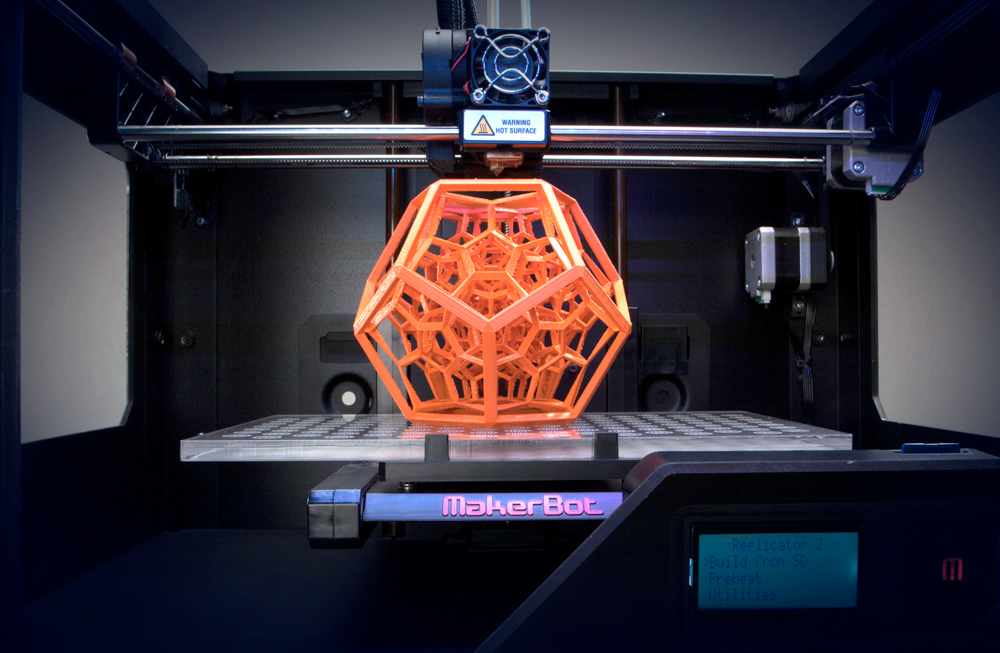

Makerbot

Makerbot  Makerbot

Makerbot

Applications: aerospace

Boeing 787 - Wikipedia

Boeing 787 - Wikipedia  Titanium Part for 787 - Norsk Titanium

Titanium Part for 787 - Norsk Titanium

Boeing is saving $3 million on each 787 jet using 3D printing

(by avoiding material waste).

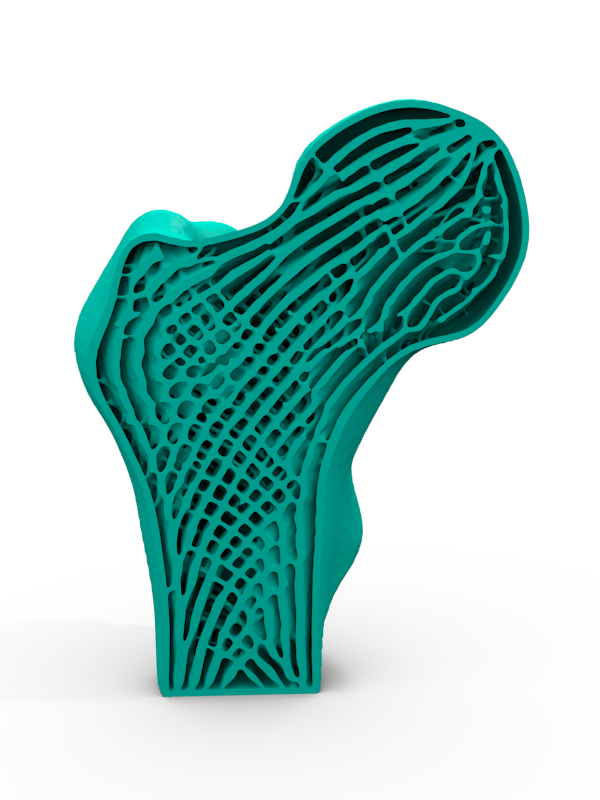

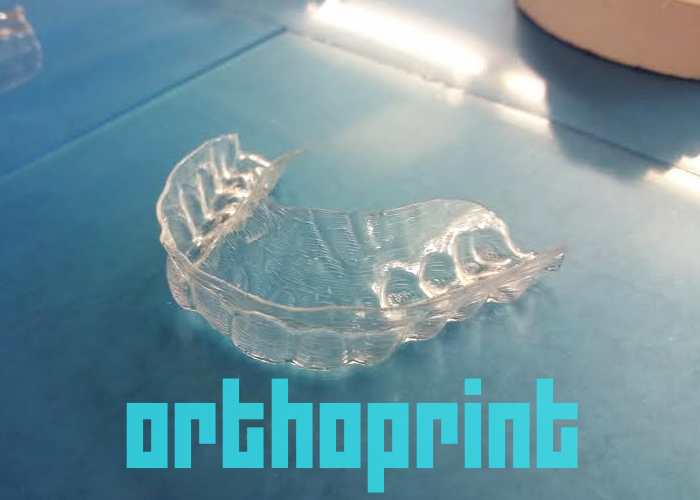

Applications: medical/dental

Robohand

Robohand  Amos Dudley

Amos Dudley

Applications: new materials

James Zhou

Create new materials by printing microstructure

Applications: shoes

Adidas and Carbon3D

Adidas and Carbon3D

Spatially varying properties for optimal sports performance

Applications: mechanical clock!

Christoph Laimer - YouTube

3D printing: technologies

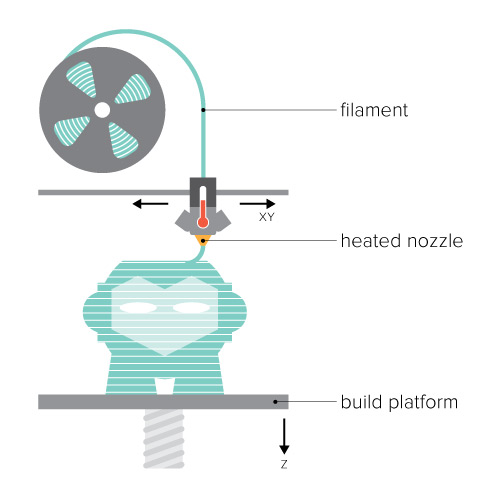

- Fused Deposition Modeling (FDM)

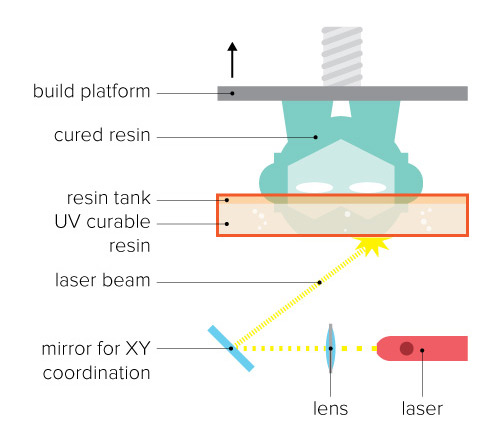

- Stereolithography (SLA)

- Selective Laser Sintering/Melting (SLS/SLM)

- Material Jetting (MJP)

- …

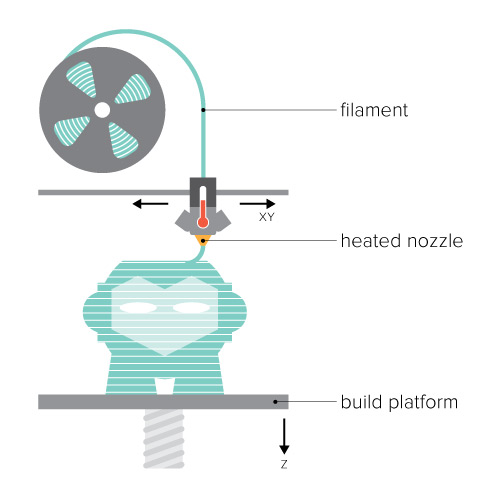

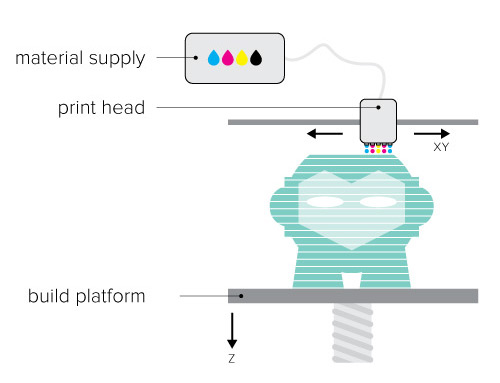

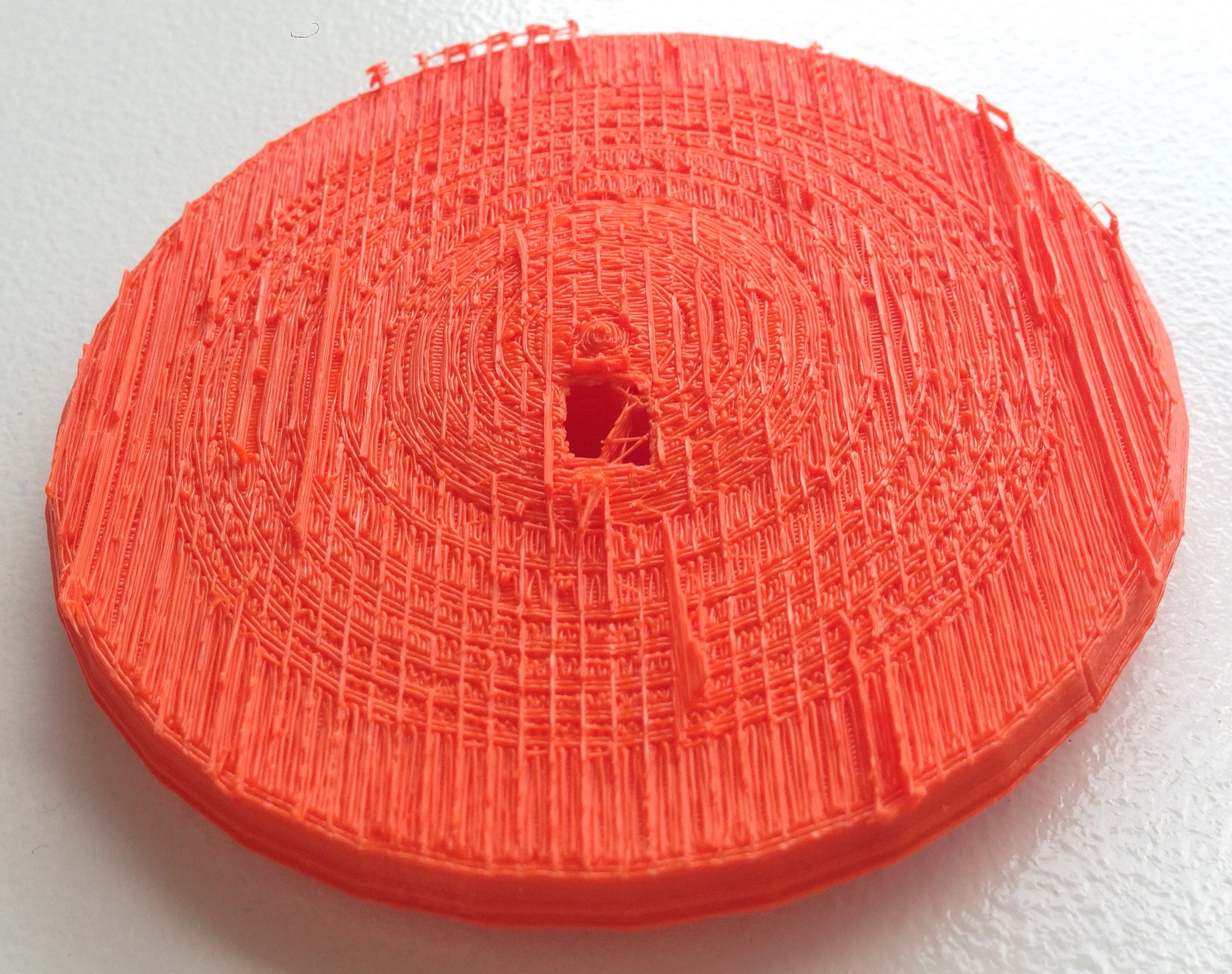

FDM technology

3D Hubs

3D Hubs

Extrude melted plastic through a nozzle to form each layer

FDM limitations

- Lower resolution; limited by

- nozzle diameter

- spatial precision of extruder head

- flow of melted plastic

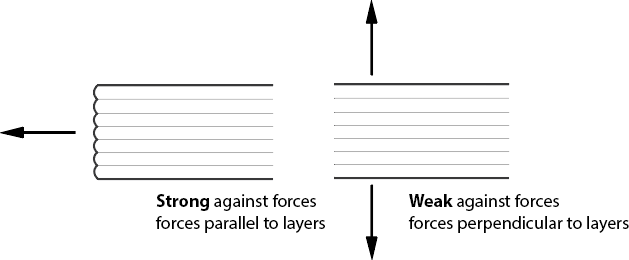

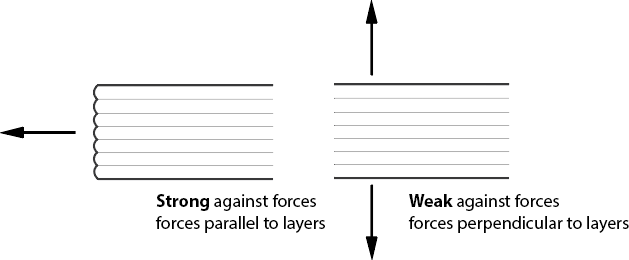

- Poor bonding between layers (anisotropic properties)

3D Hubs

3D Hubs

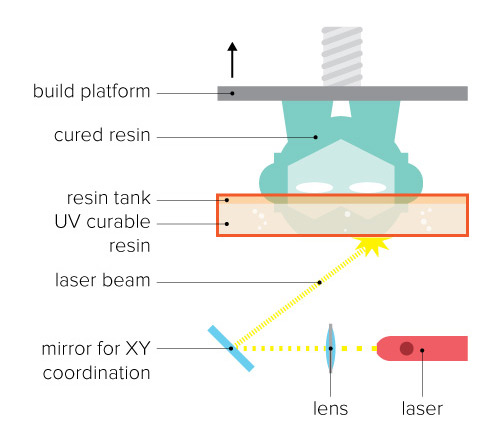

SLA Technology

3D Hubs

3D Hubs

Cure liquid resin into a solid by shining UV light

3D printing: DLP SLA (B9 Creator)

Project and cure entire layer geometry simultaneously

SLA pros and cons

- Advantages

- Excellent resolution (25um layer height)

- Layers almost perfectly bind; isotropic properties

- Wide range of resins to choose from

- Disadvantages

- Requires cleaning and curing postprocess (place in UV oven)

- Color and mechanical properties shift over time as curing continues

- Only one material at a time

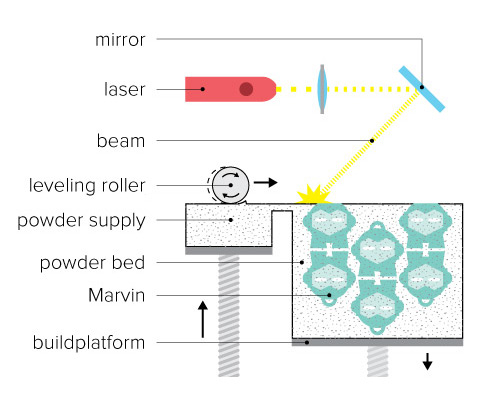

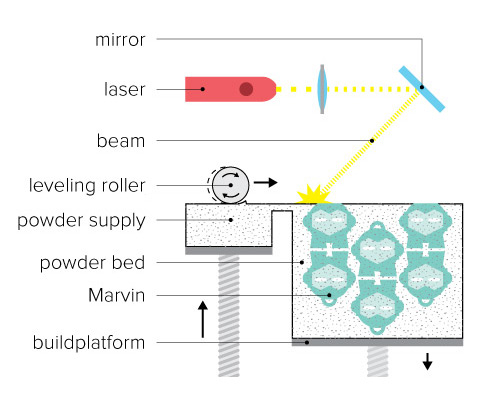

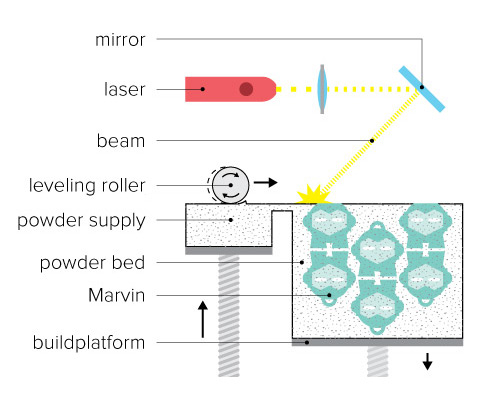

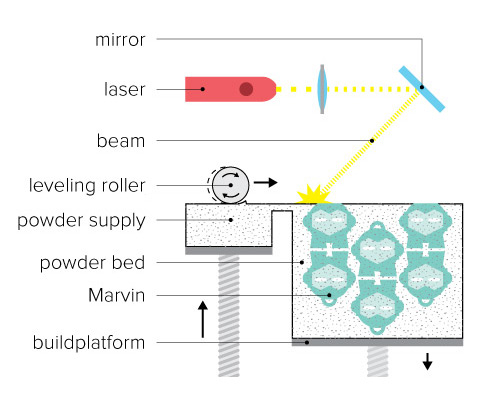

SLS/SLM Technology

3D Hubs

3D Hubs

Laser shines on a bed of plastic or metal powder, fusing or melting the particles into a solid part.

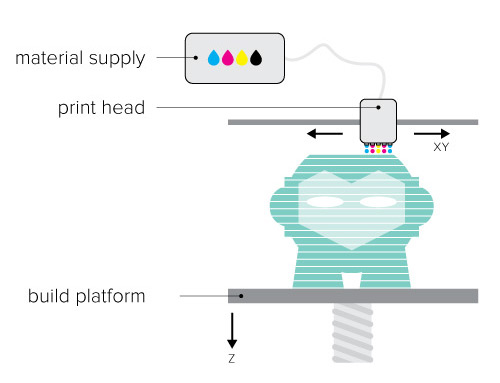

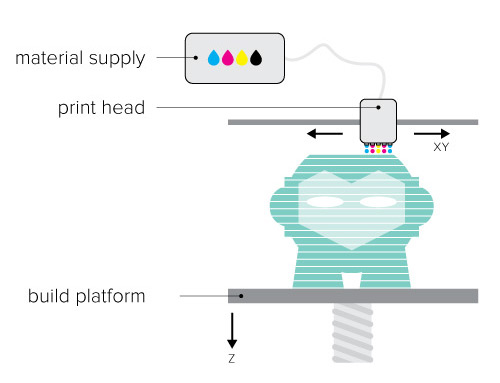

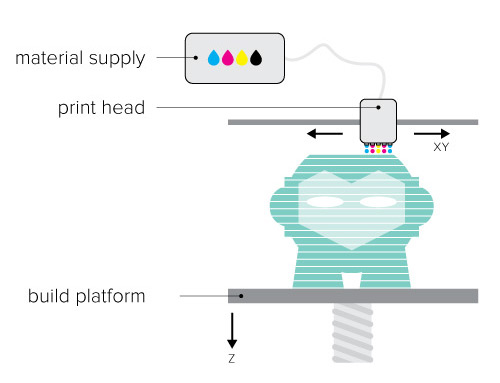

Material Jetting Technology

3D Hubs

3D Hubs

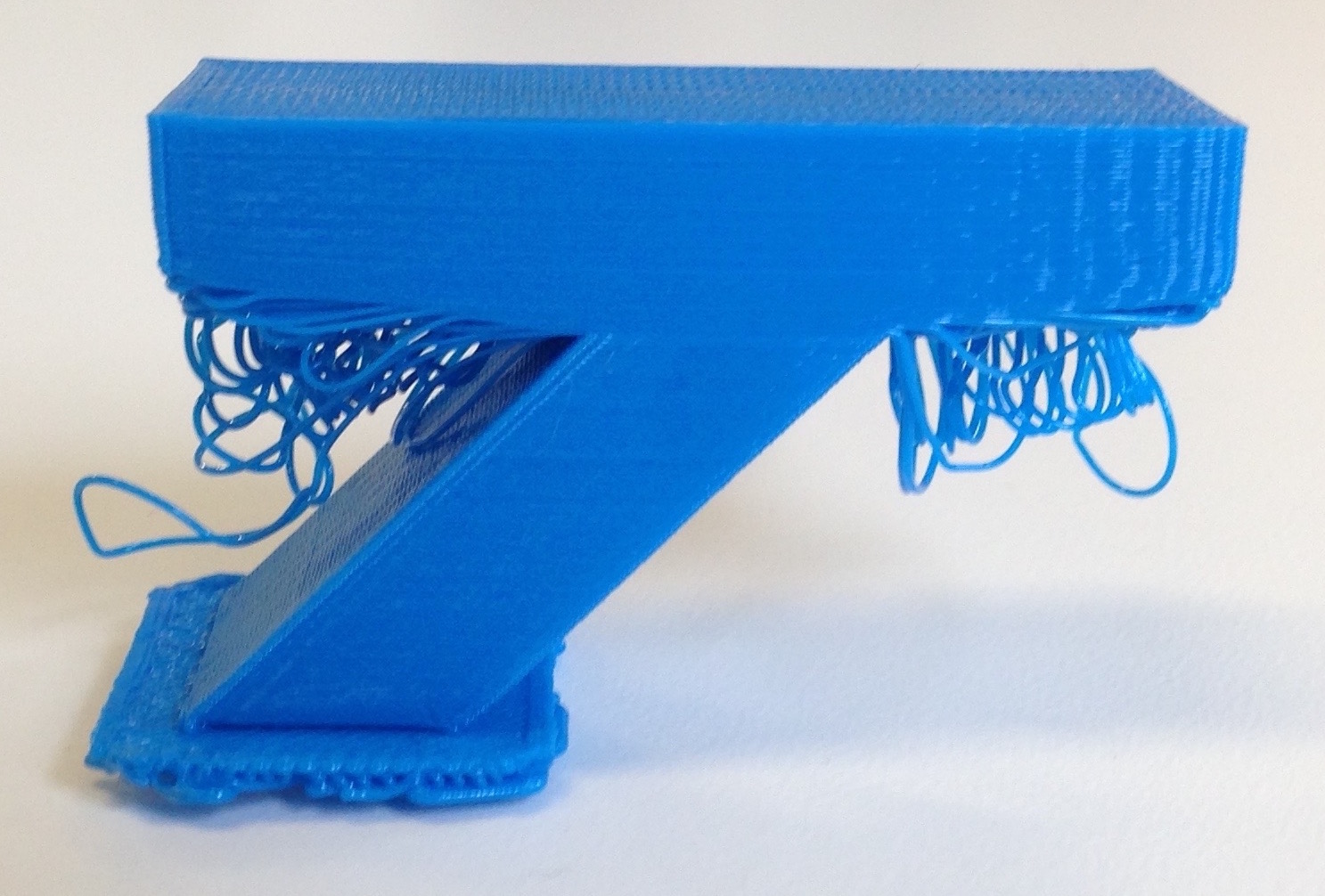

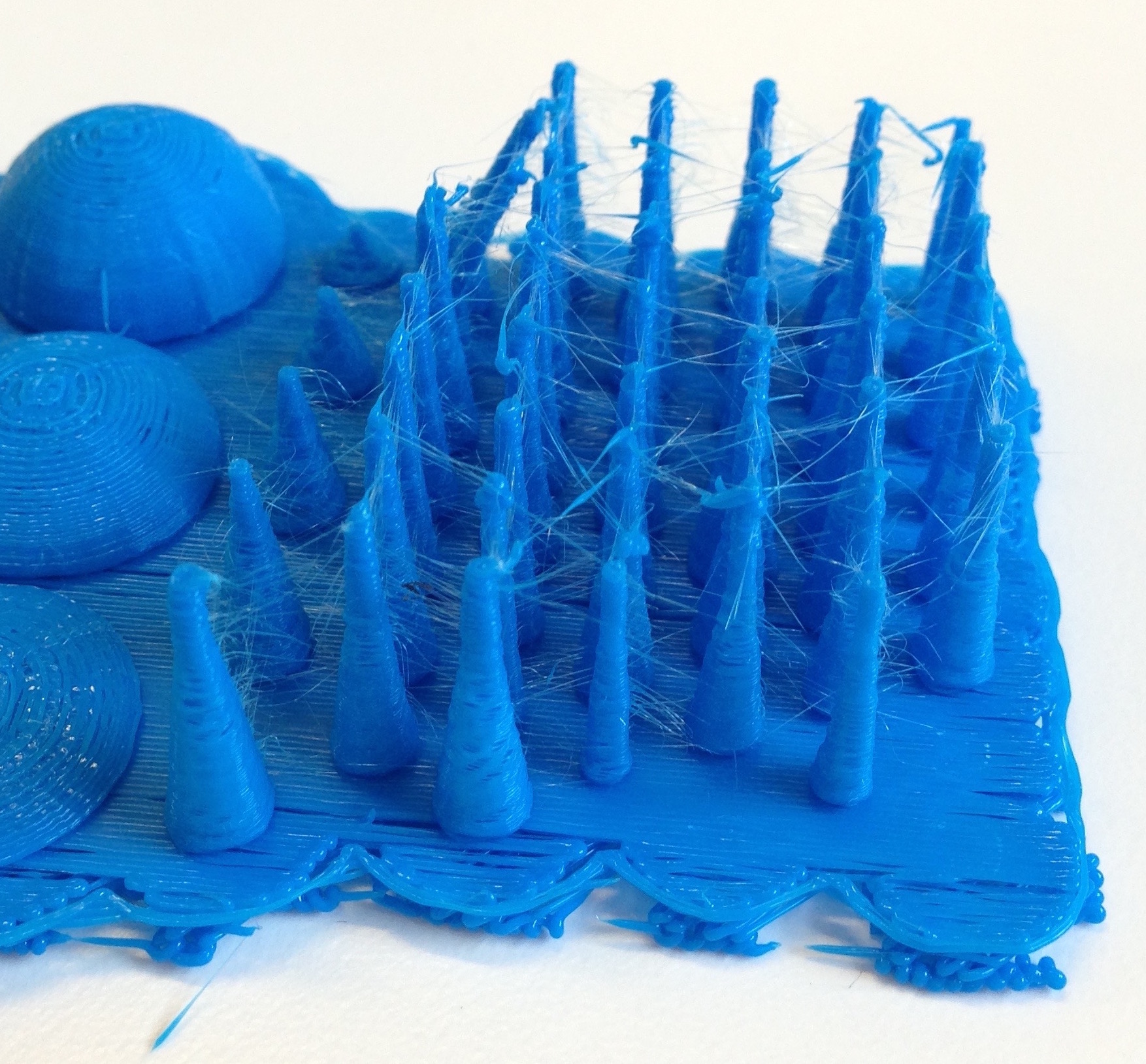

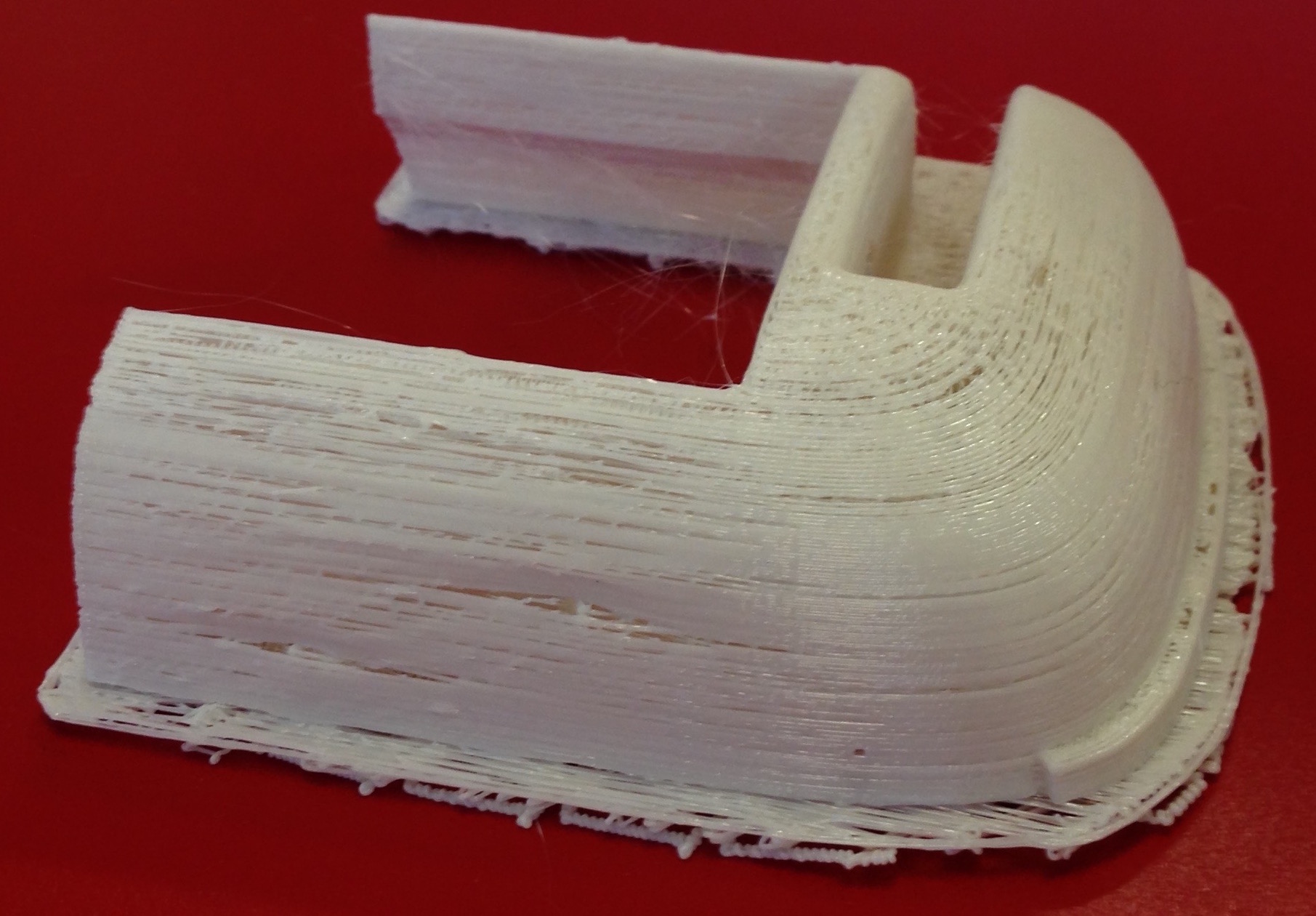

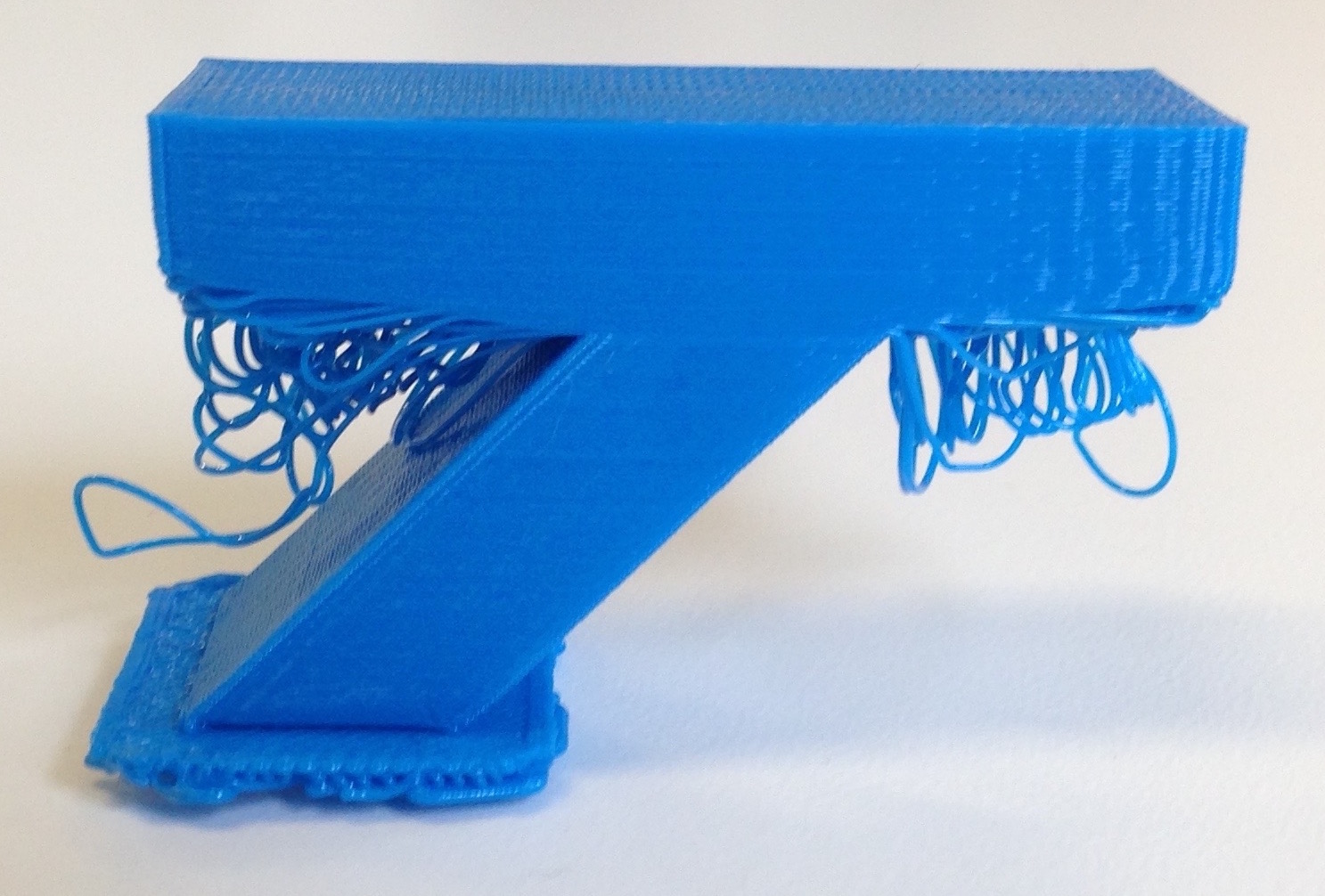

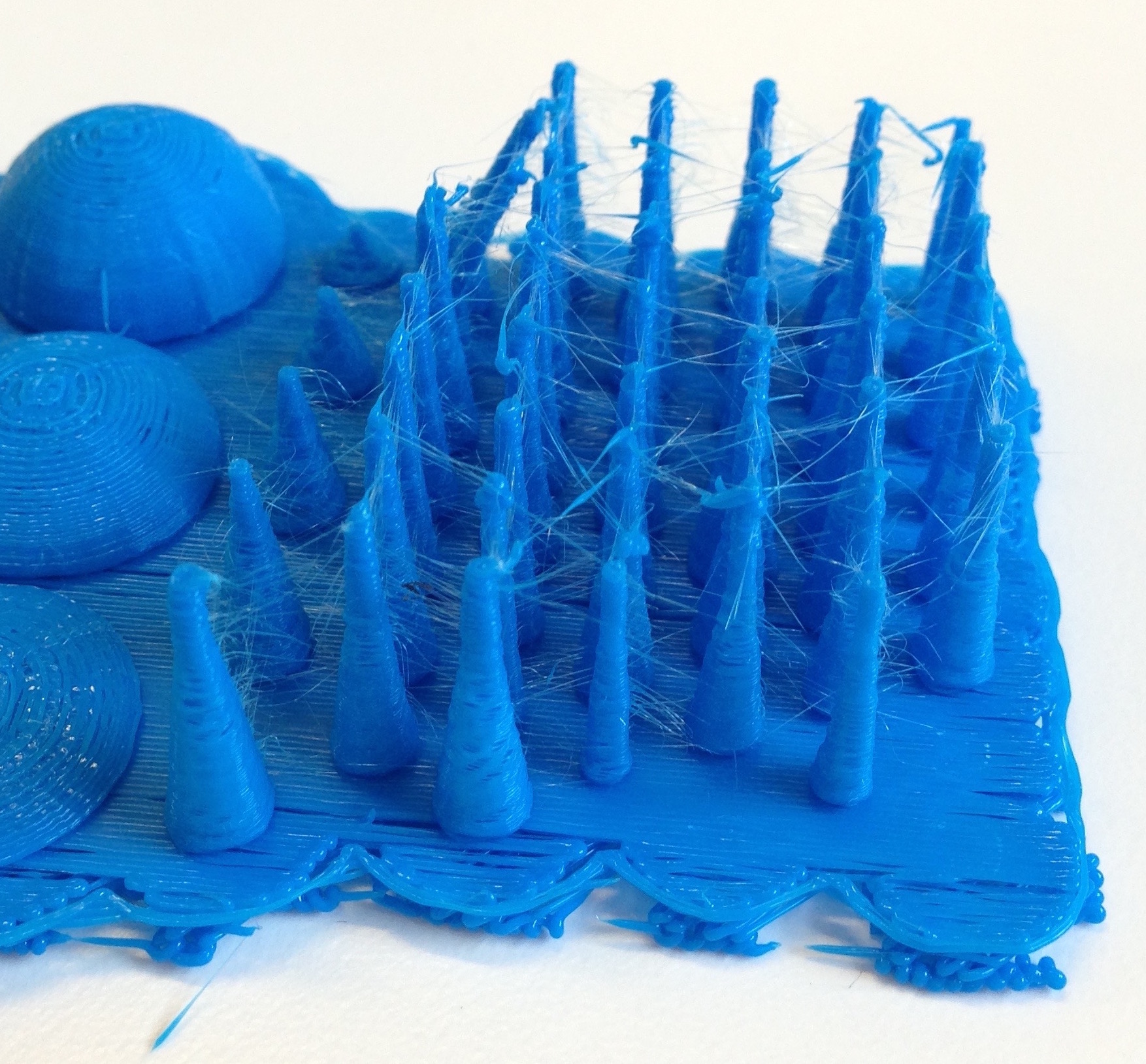

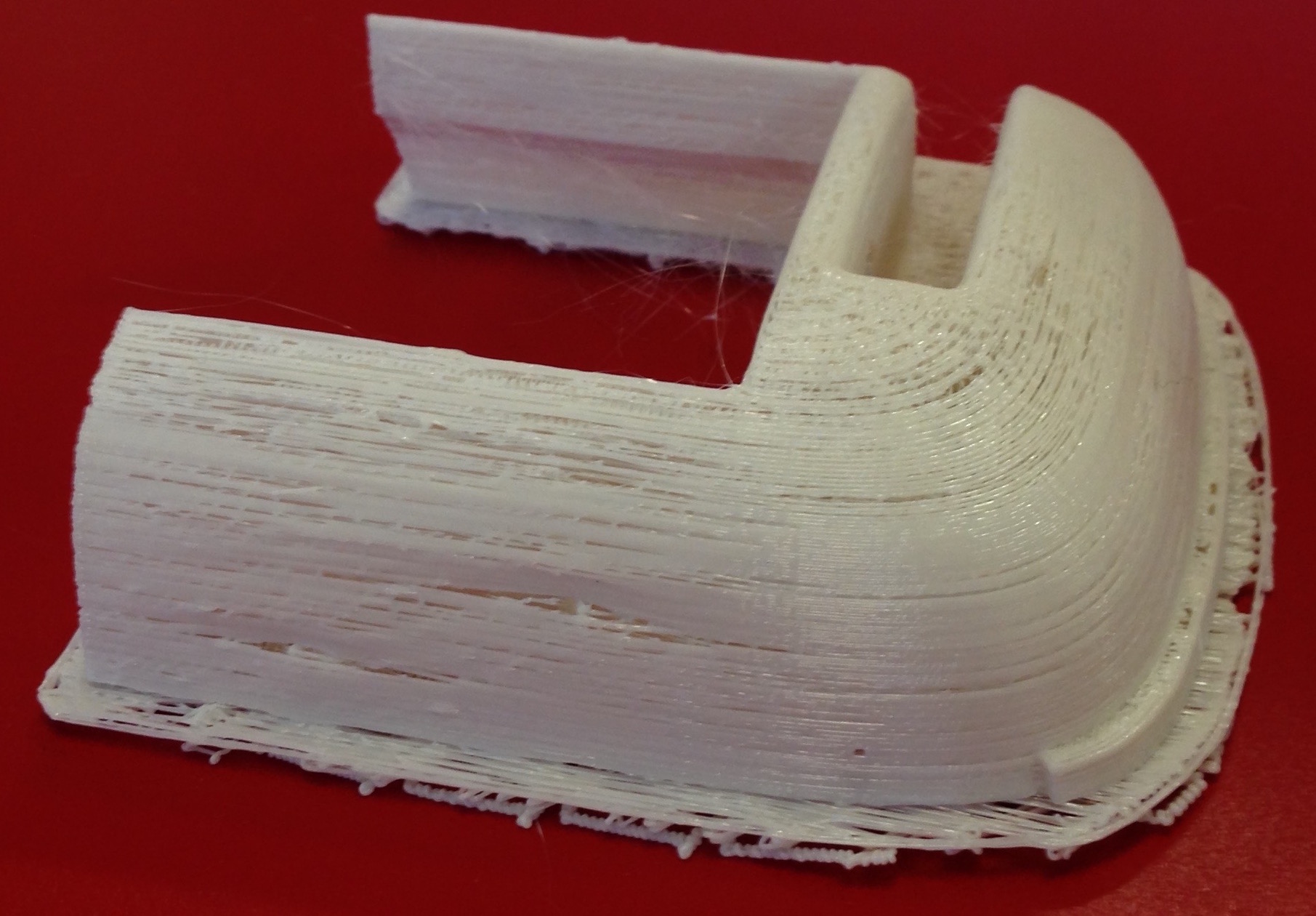

3D printing: what can go wrong?

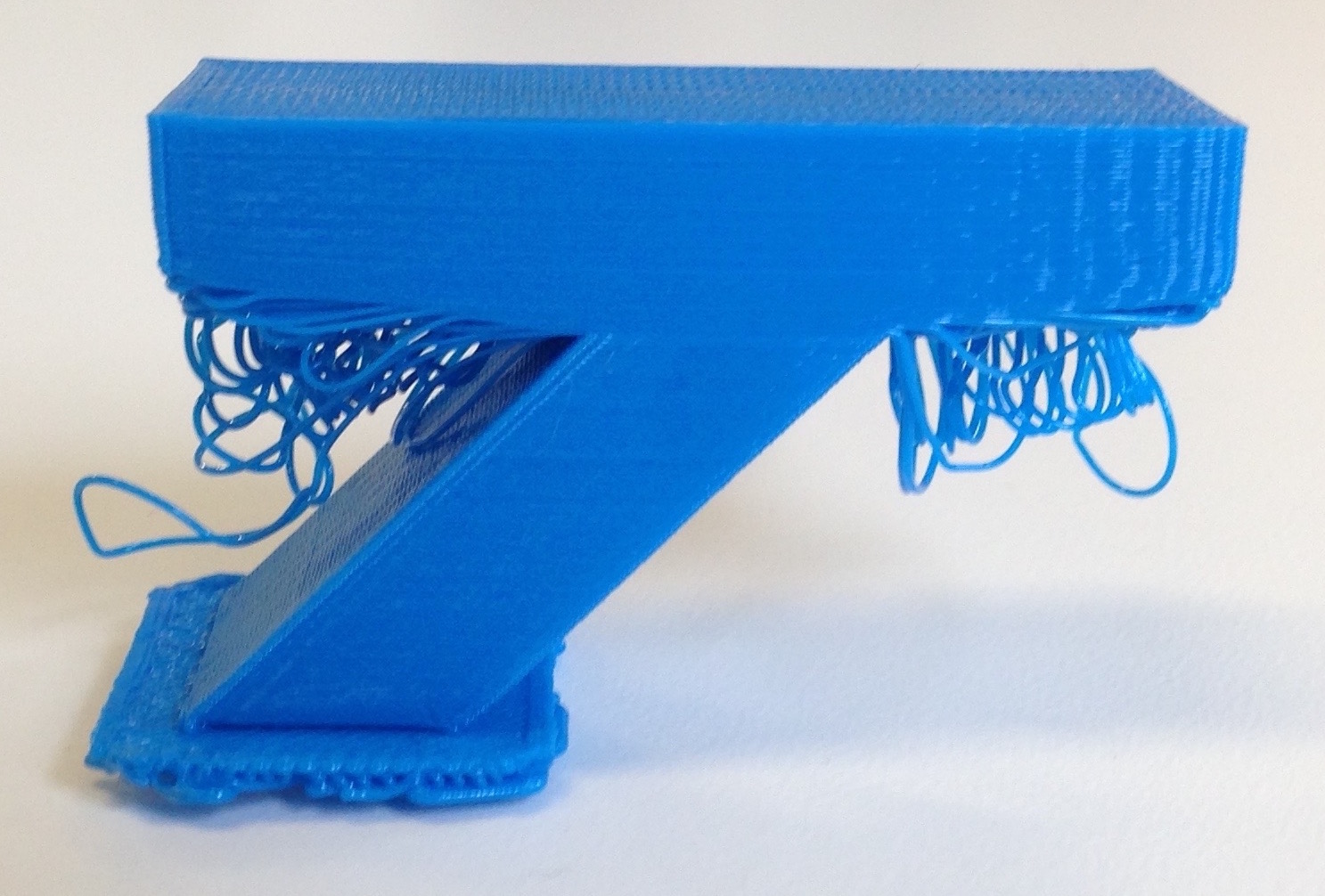

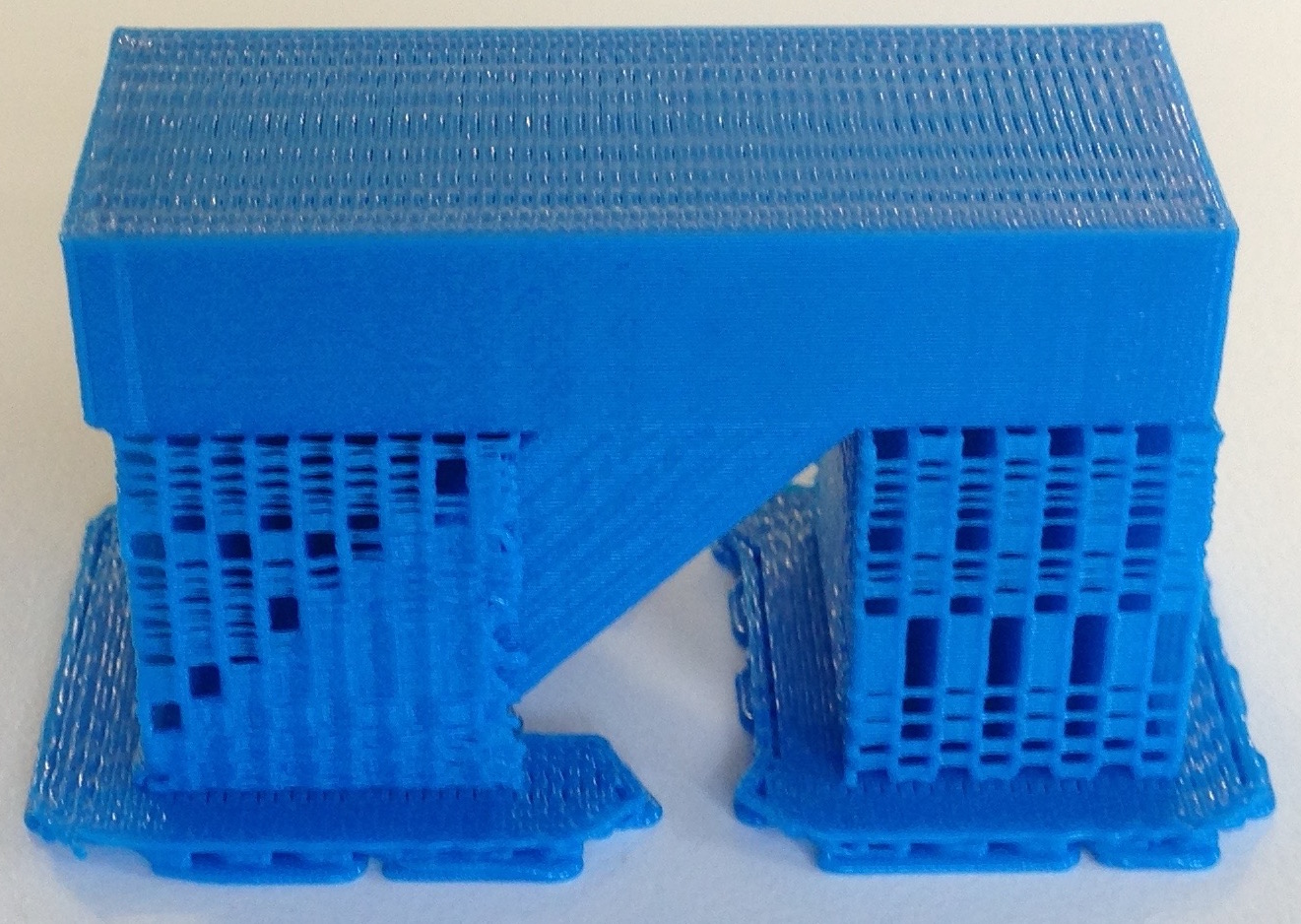

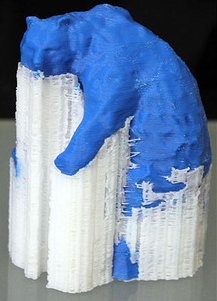

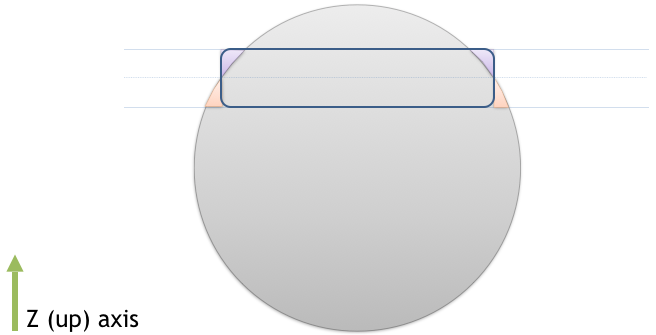

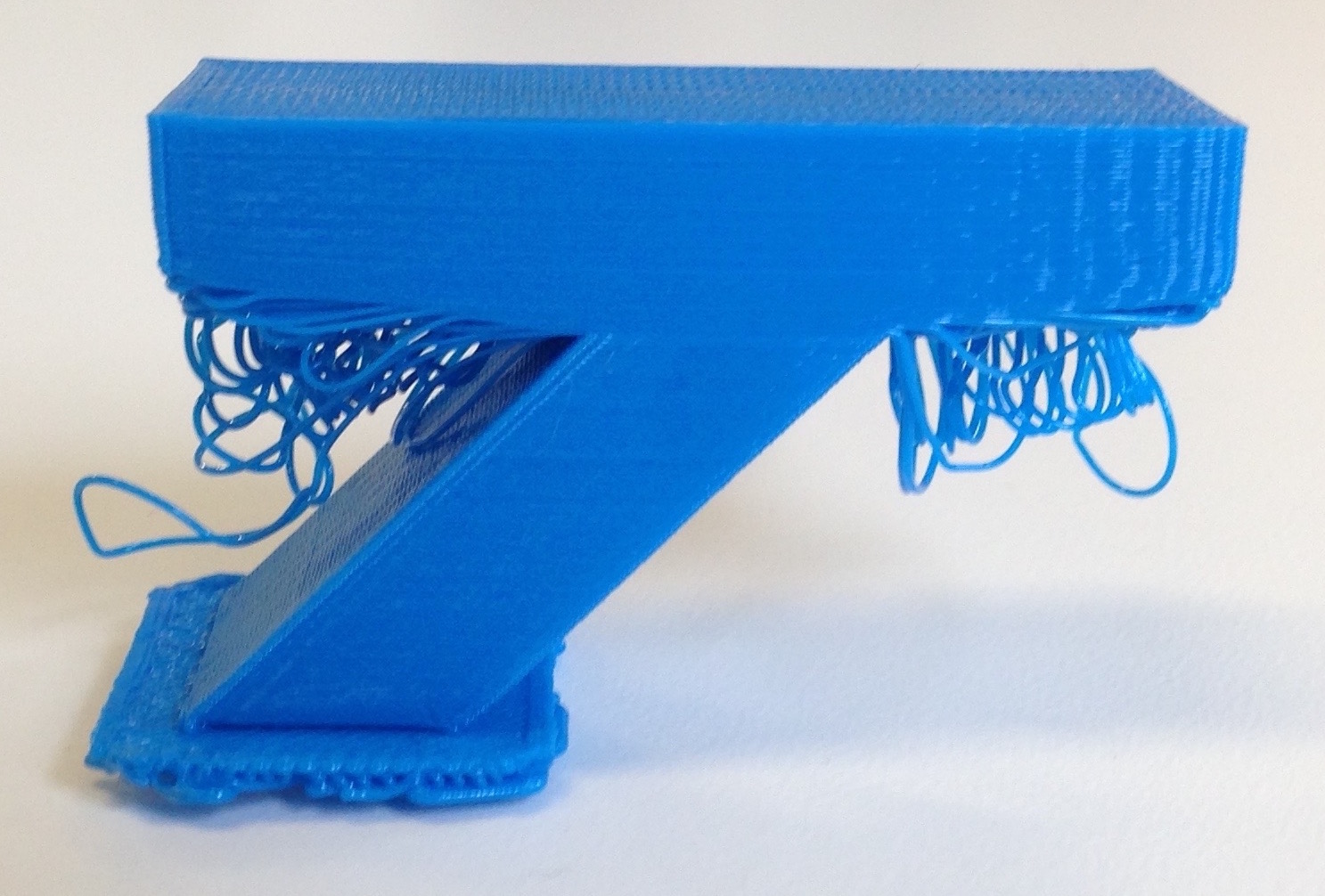

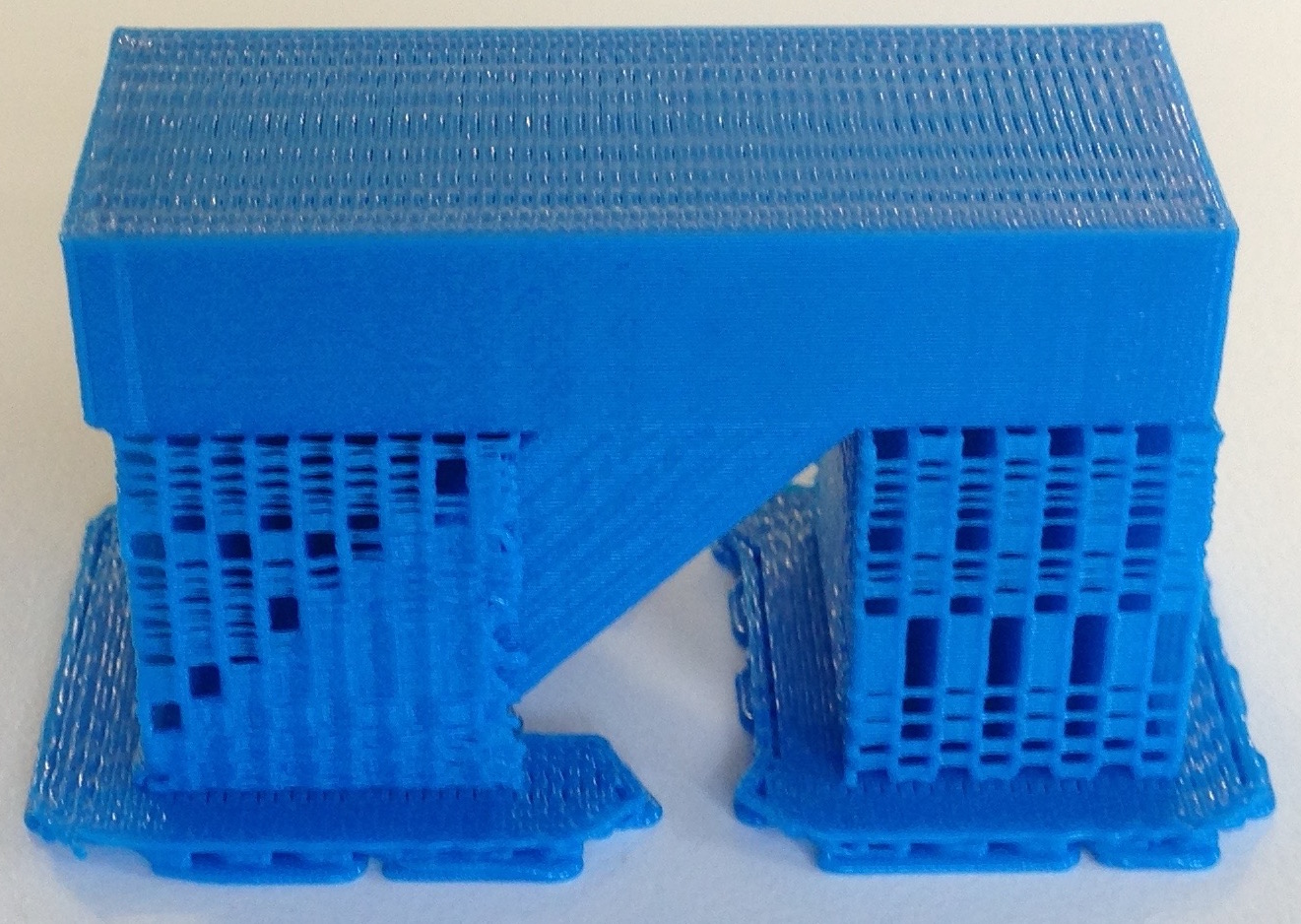

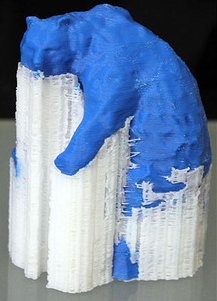

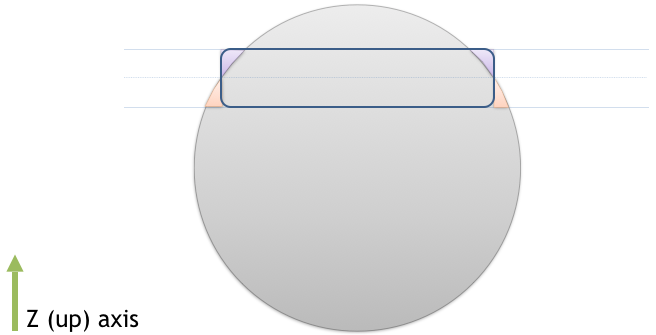

3D printing: support structure

The defect on the overhanging feature is caused by insufficient support; support structure required.

SLA can print overhangs, but not local minima (e.g., bear hand).

3D printing: support structure removal

Removing support can be difficult or completely intractable.

3D printing: support structure for SLS

3D Hubs

3D Hubs

SLS doesn’t need support structure!

3D printing: support structure for Multijet

3D Hubs

3D Hubs

Multijet printers can print with dissolvable support!

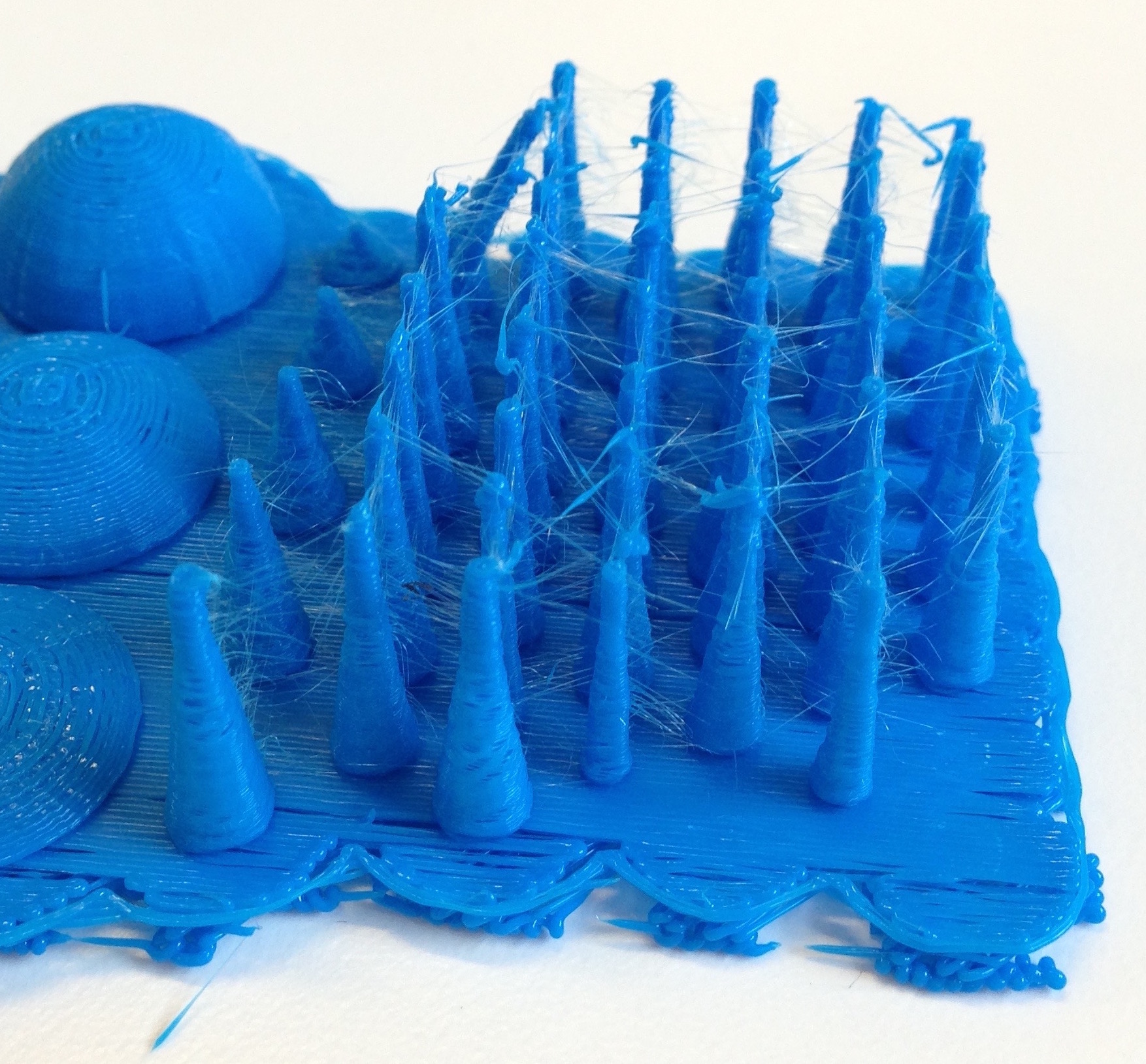

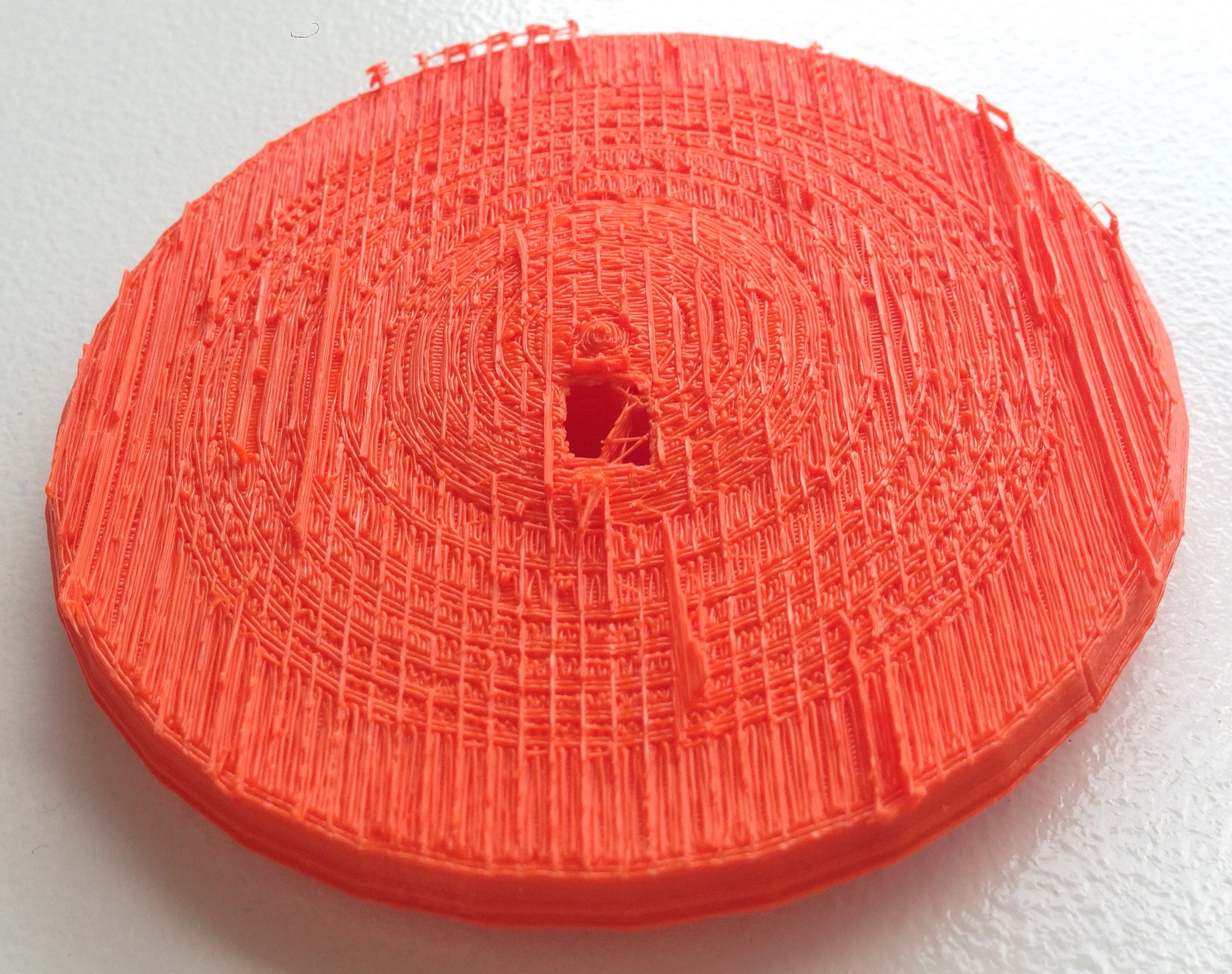

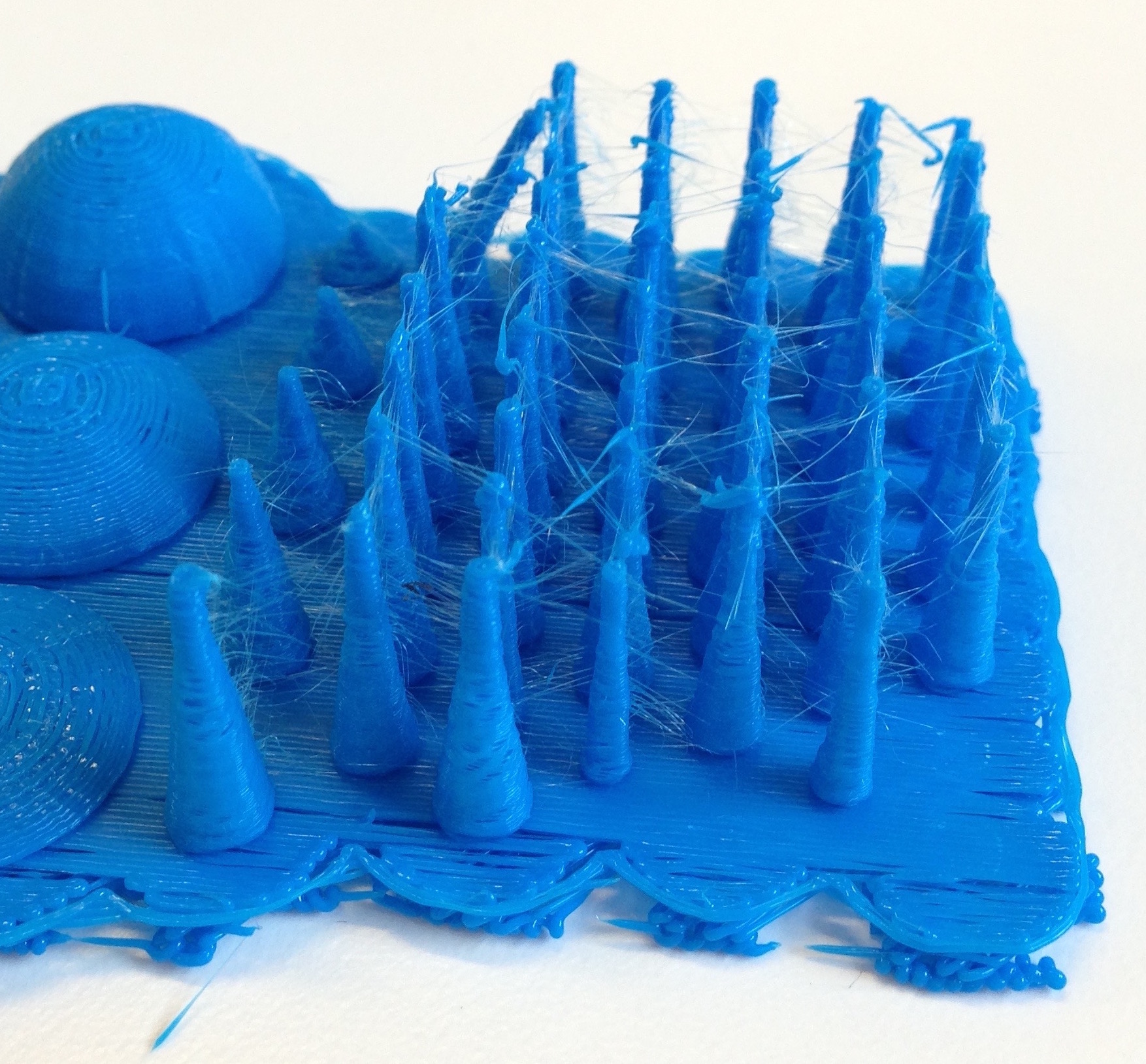

3D printing: stringing and gaps (FDM)

Stringing can be fixed by lowering temperature/speed or asking printer to retract filament.

Gaps can be fixed by increasing the extrusion rate.

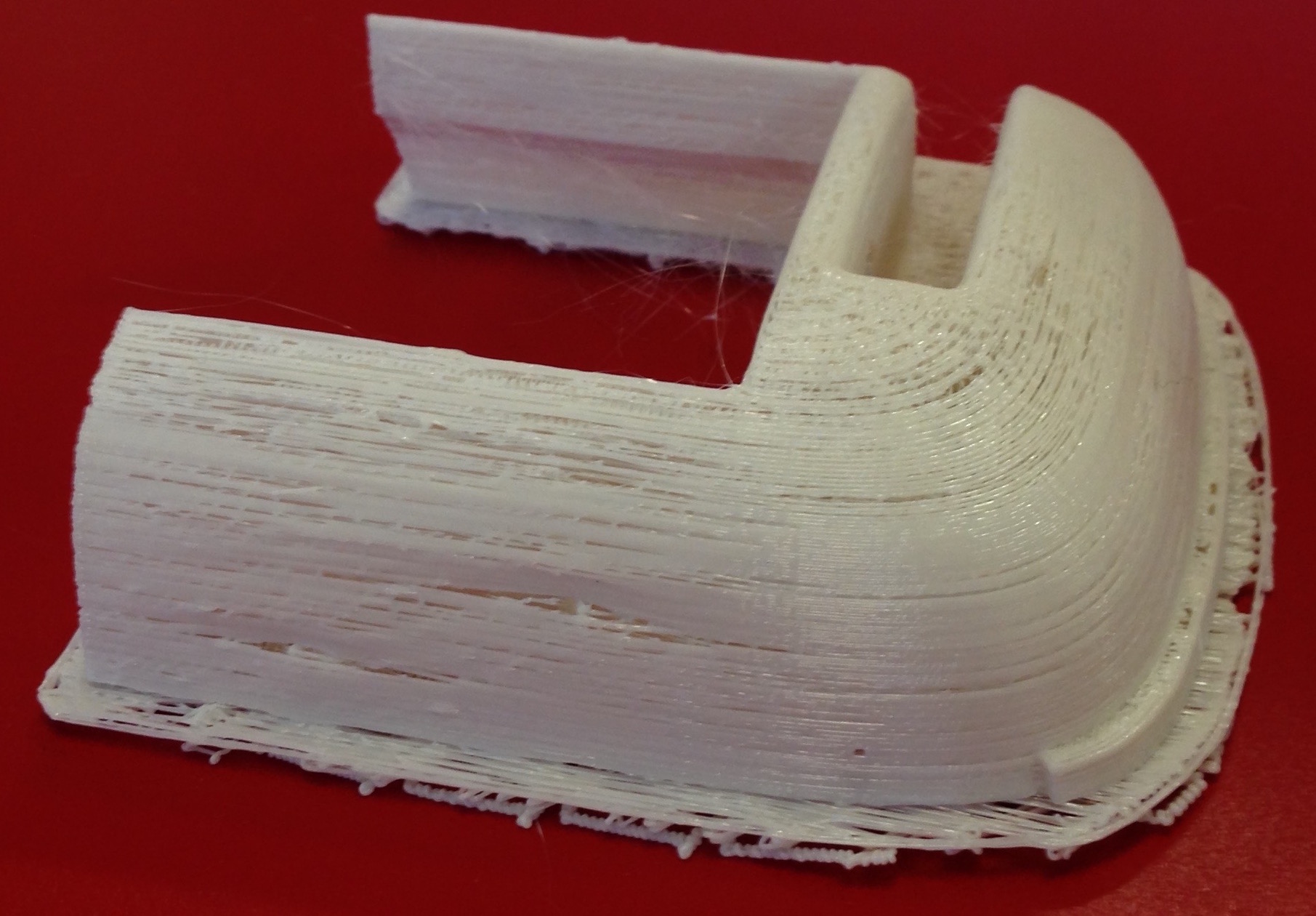

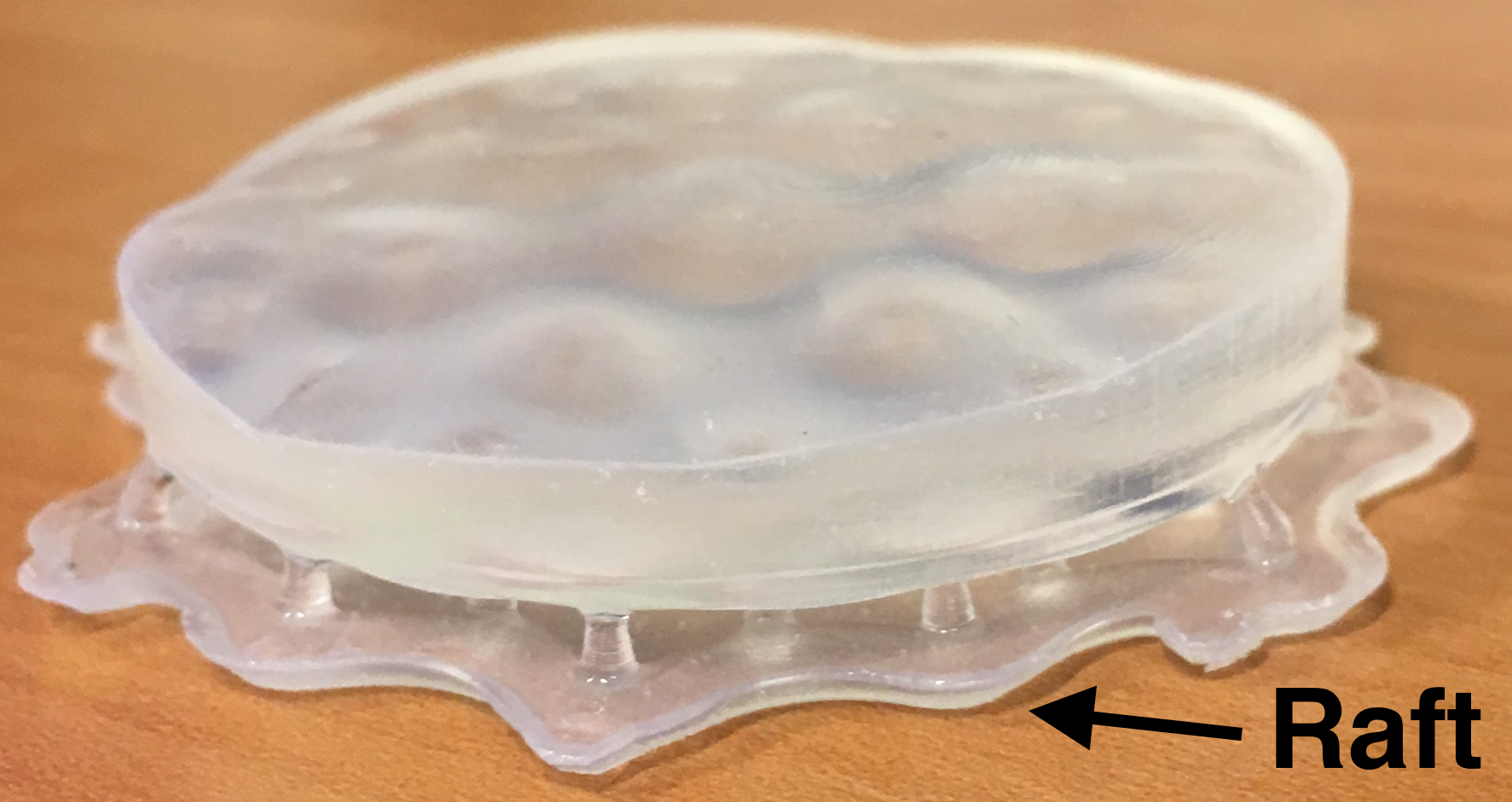

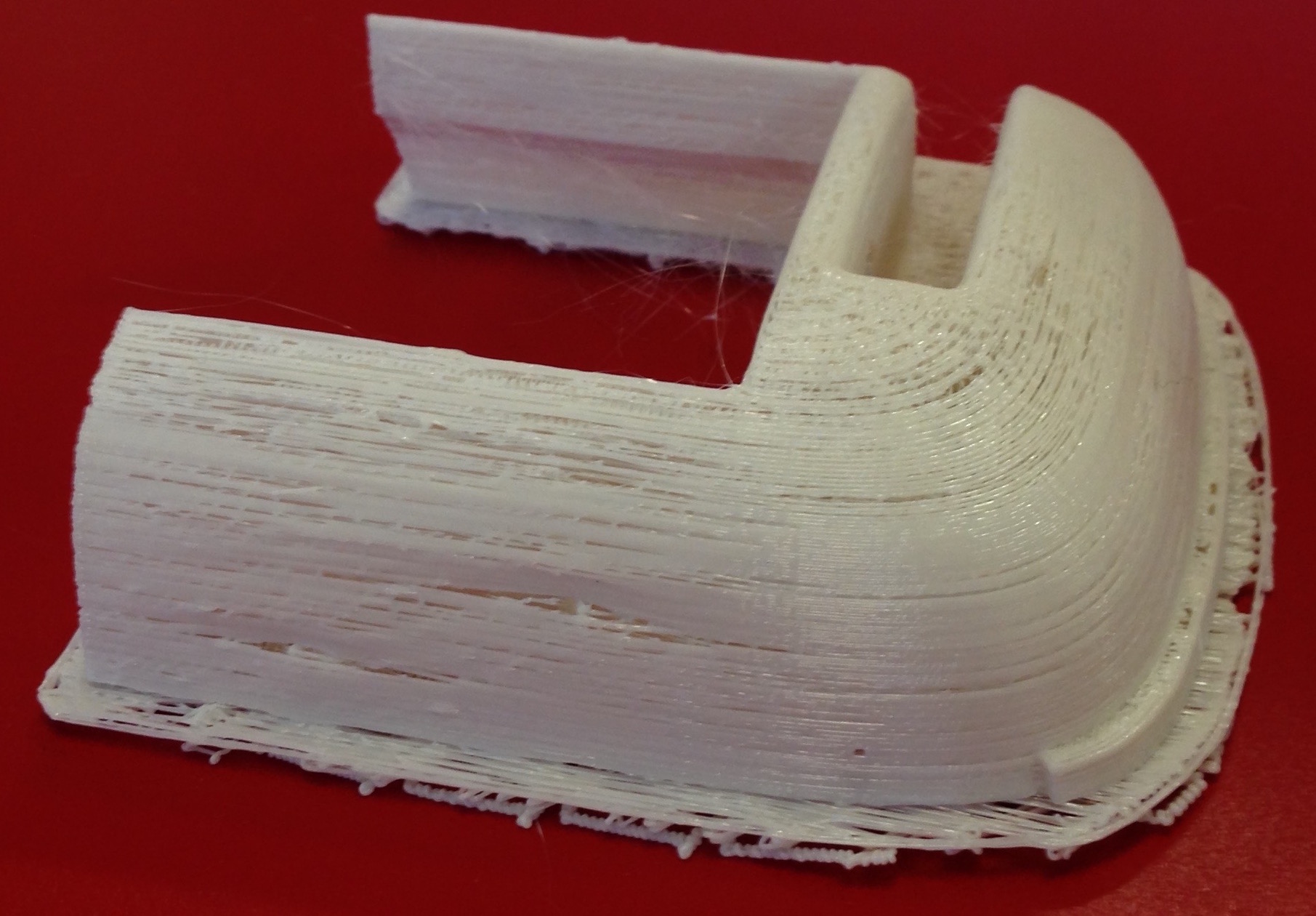

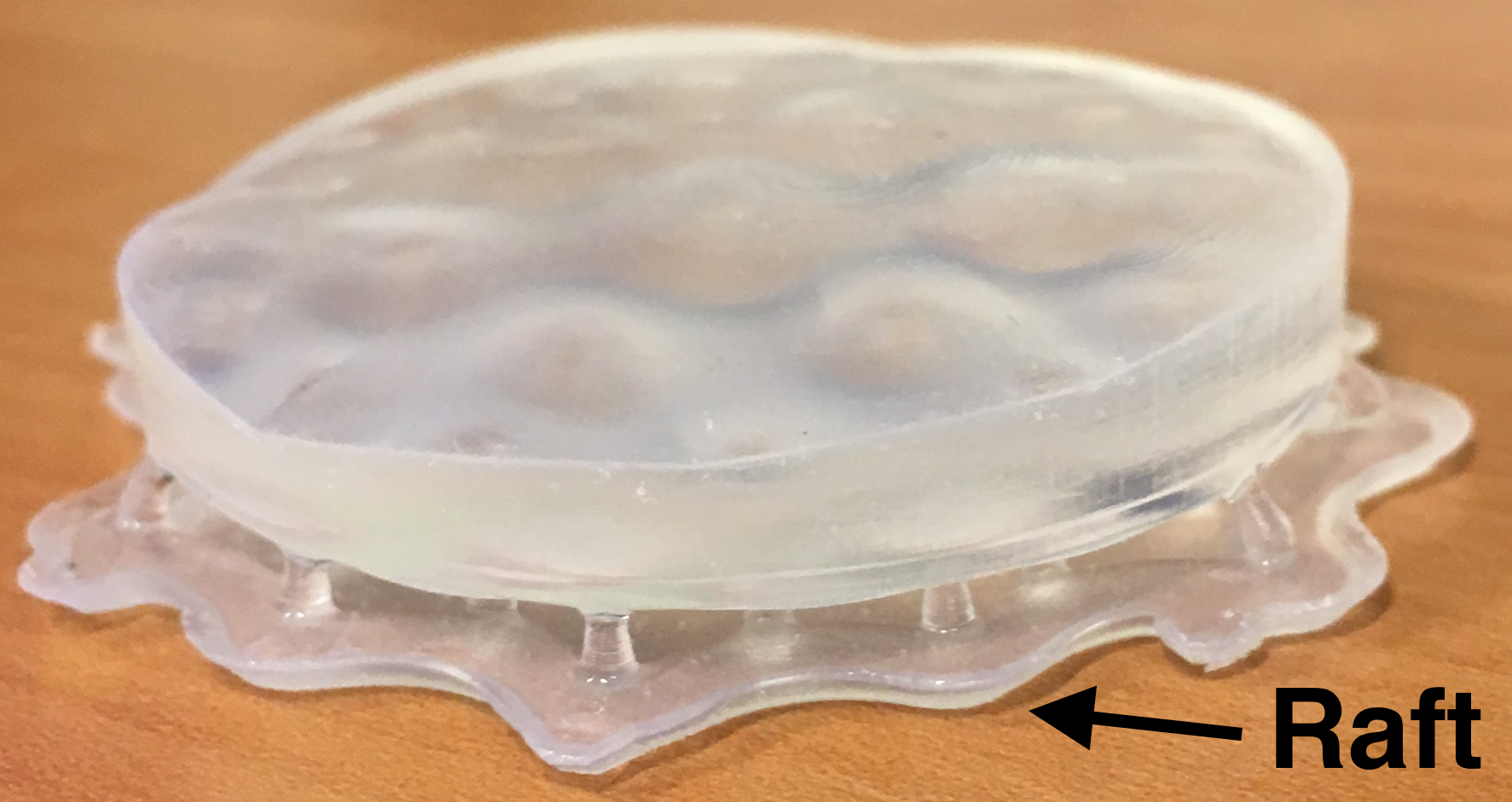

3D printing: warping (FDM and SLA)

First few layers can warp/peel from build platform.

Consider printing on “raft.”

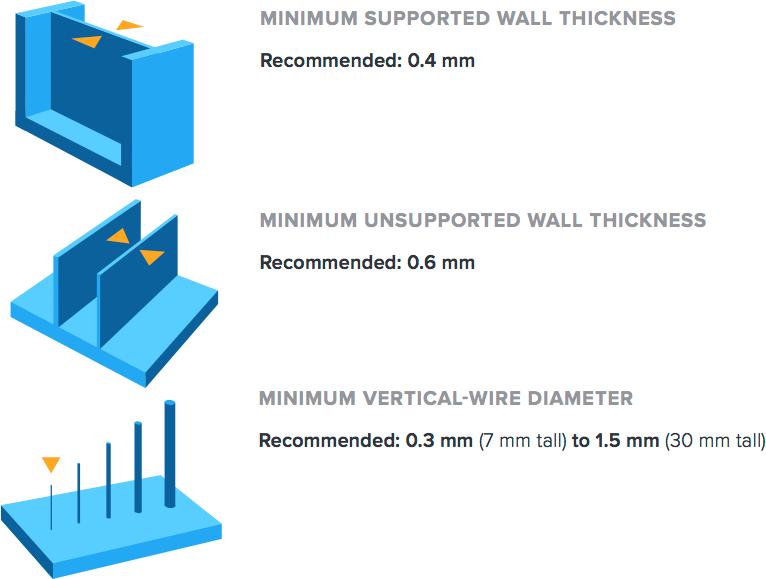

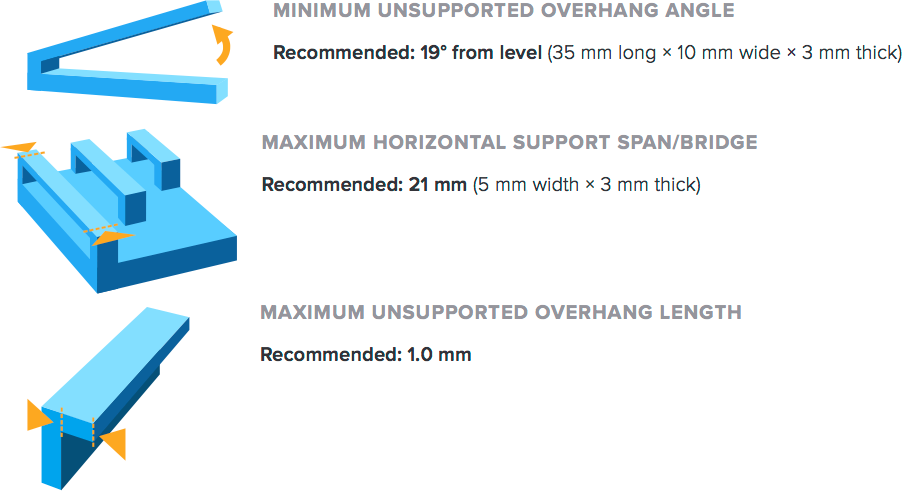

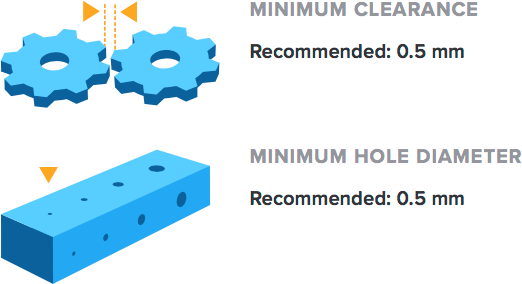

3D printing: design rules

- Minimum thickness constraints

3D printing: design rules

- Minimum thickness constraints

- Support requirements

3D printing: design rules

- Minimum thickness constraints

- Support requirements

- Clearance requirements

3D printing: design rules

- Minimum thickness constraints

- Support requirements

- Clearance requirements

- No enclosed voids (SLA/SLS)

Optimizing for 3D printing

What exactly can we optimize?

- Printing parameters

- Support structure

- The design itself

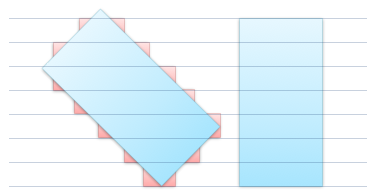

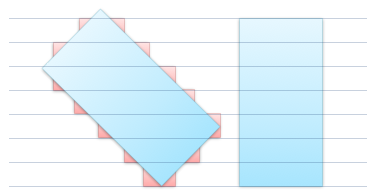

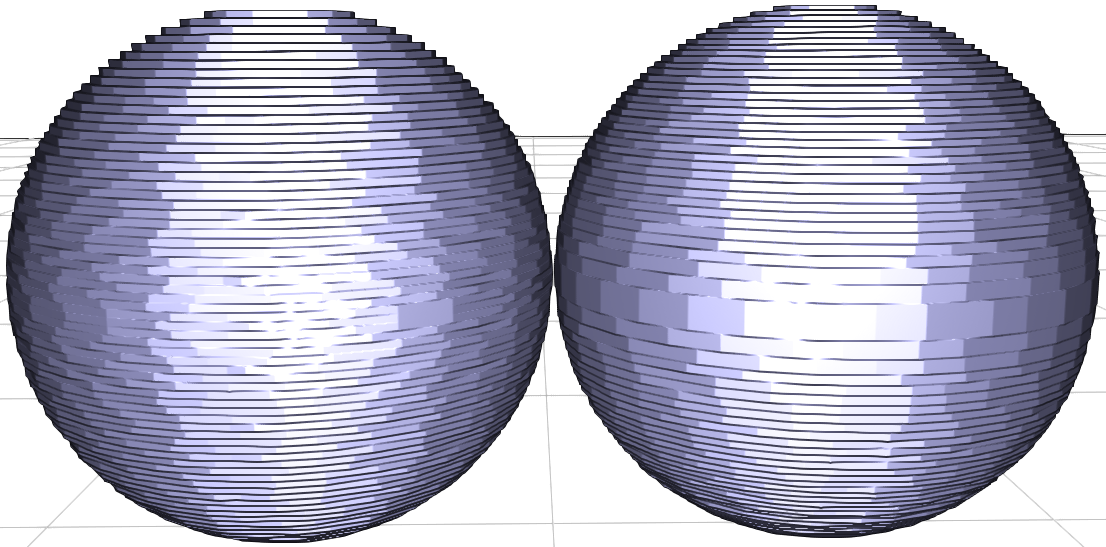

Optimizing printing parameters

- Adjust orientation/slicing to

- minimize print error

- keep prints fast: use adaptive slicing!

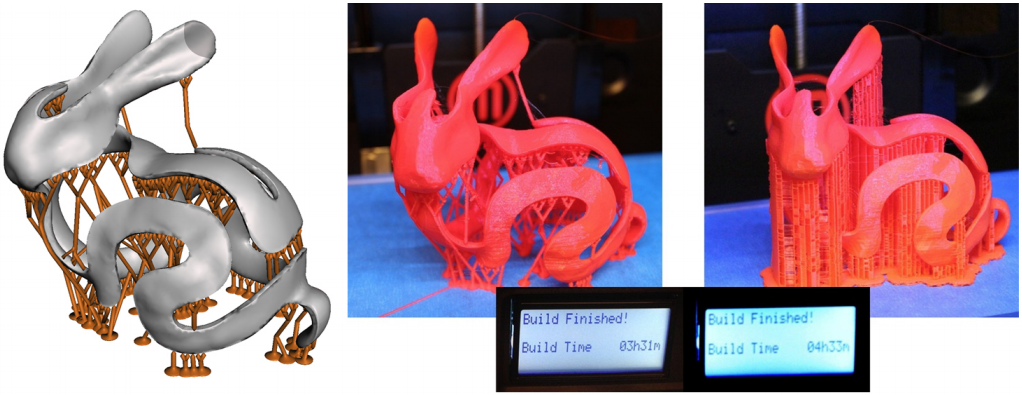

Optimizing support structure

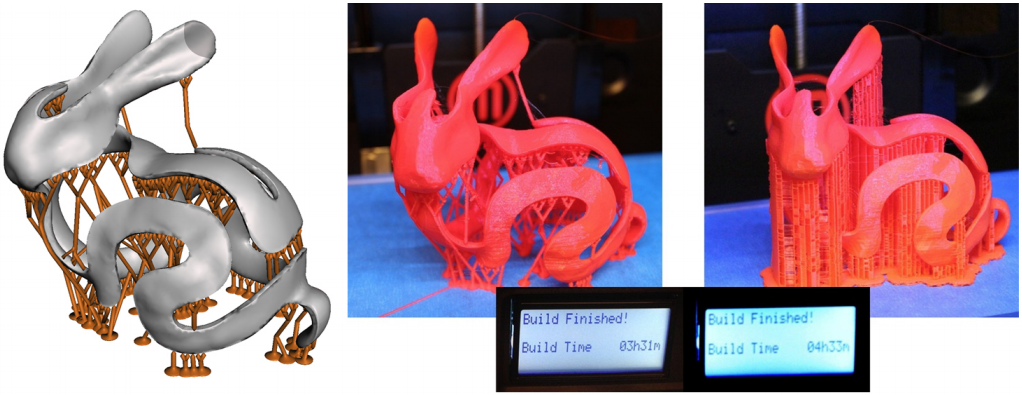

Branching Support Structures for 3D Printing: Ryan Schmidt and Nobuyuki Umetani

Branching Support Structures for 3D Printing: Ryan Schmidt and Nobuyuki Umetani

These branching supports use 75% less material than the manufacture’s default support structure–reduce print time/cost.

(Note: part orientation matters here too!)

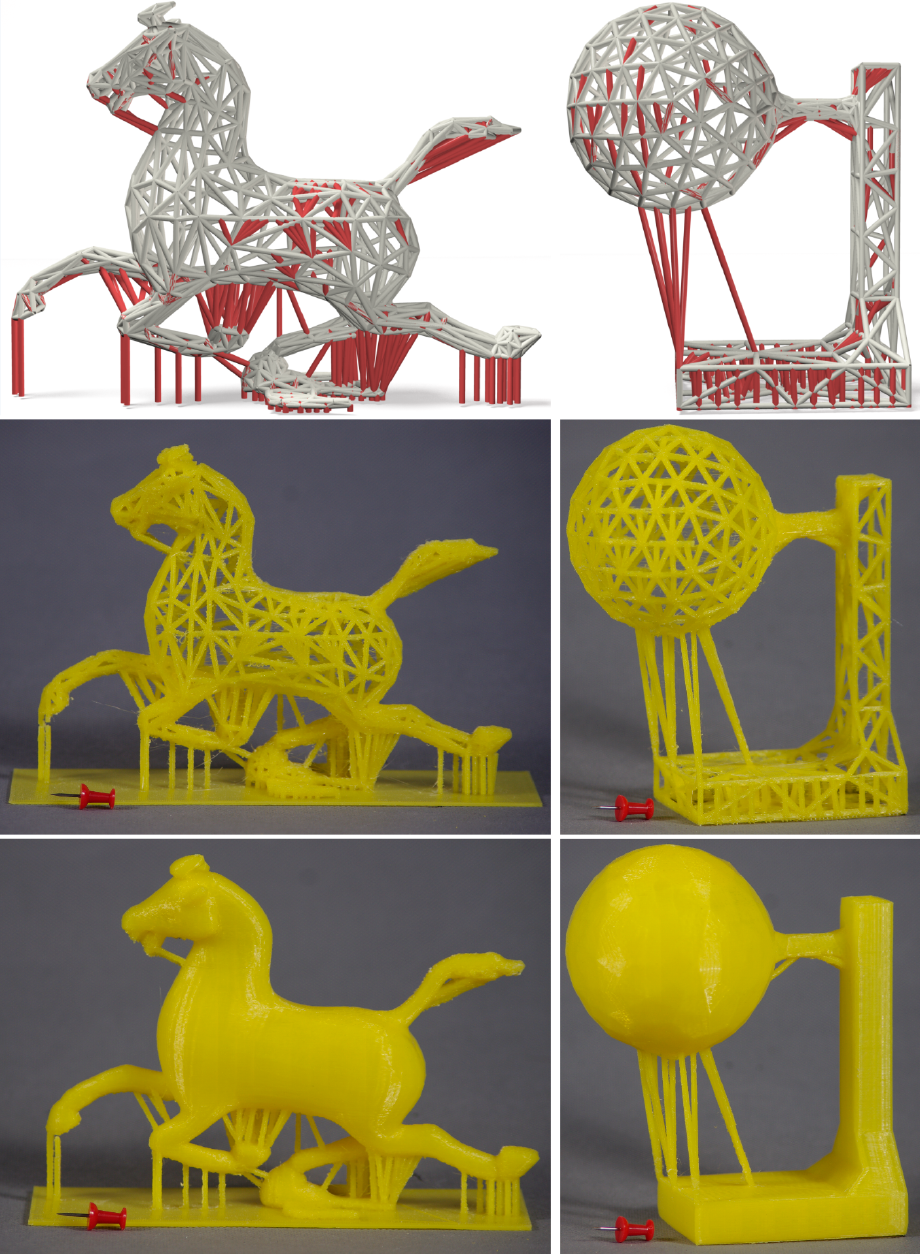

Minimize printing costs/maximize robustness

- Optimize printed design itself

- minimize printed volume without breaking

- maximize resilience for given print volume

- Cost-effective Printing of 3D Objects with Skin-Frame Structures

[Wang et al. 2013]

Fabrication services

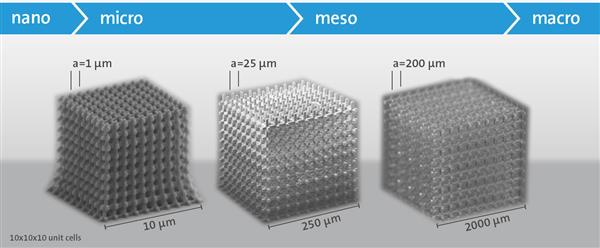

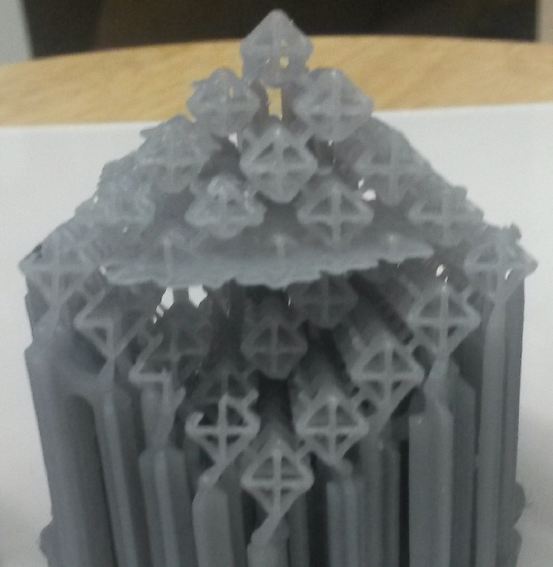

Pushing 3D printing to the extremes

Large scale: concrete printers

Andrey Rudenko - Youtube

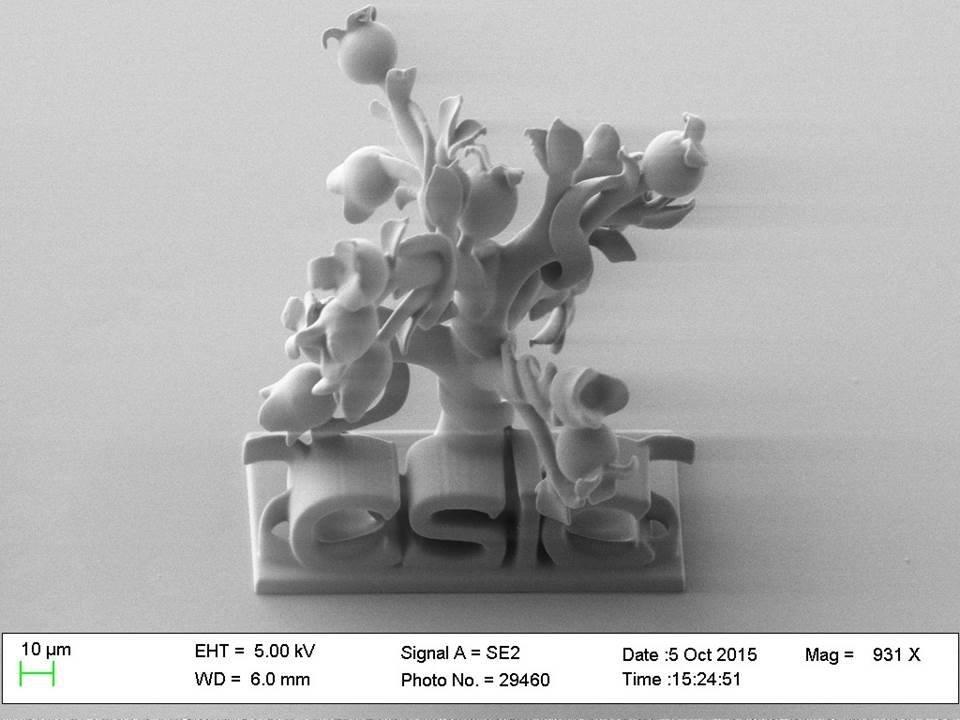

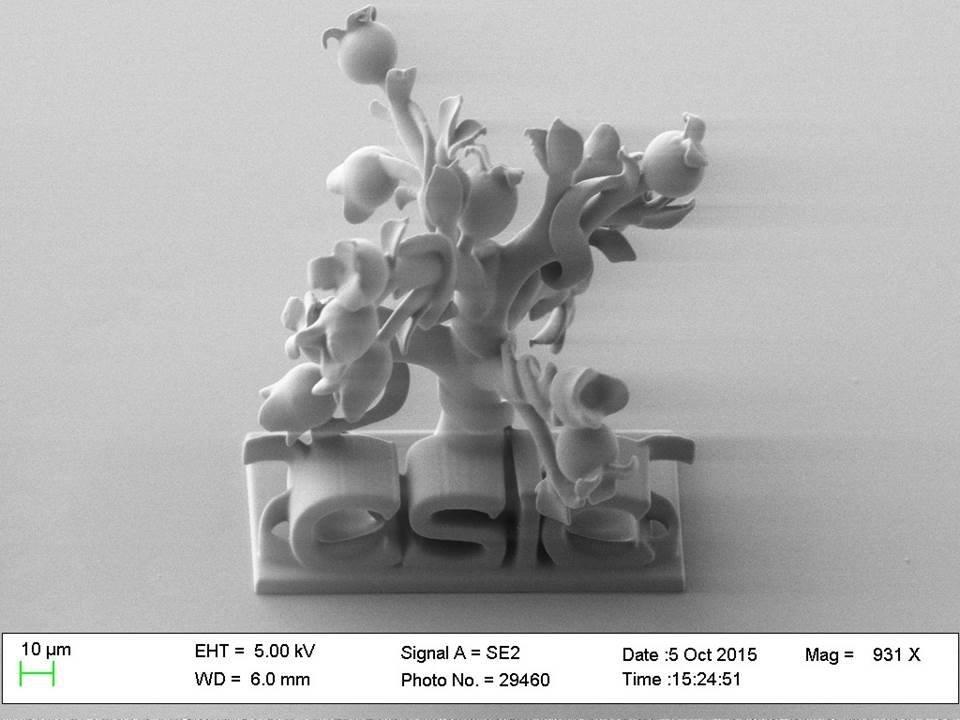

Pushing 3D printing to the extremes

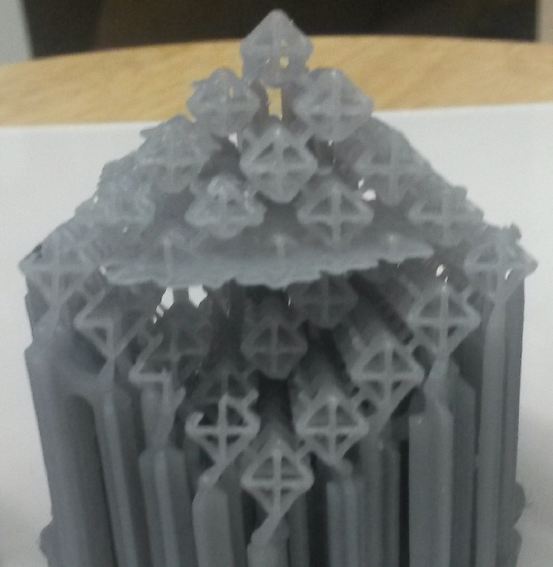

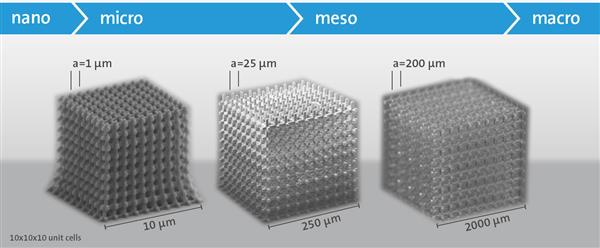

Small scale: nanophotonics

Nanoscribe

Nanoscribe  Two photo lithography - nffa.eu

Two photo lithography - nffa.eu

Microstructure with nanoscribe

Microstructure with nanoscribe